twas_brillig

Jedi Knight

Offline

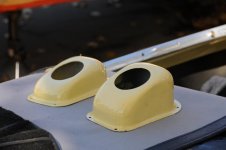

Jeff (known here as 67hardtop) has created a fibreglas duplicate of the BE shifter cupola in fibreglas, but an inch lower. It takes the standard BE shifter boot, but is now low enough to allow the five speed to be shifted without interference.

You can see the original metal, primrose yellow, version and the rattle can painted fibreglas semi-clone. Apologies, but the only photo if have of it installed is in the white, unpainted, protoype form. Jeff's looking into producing more if there's interest. It works well on our yellow 59, and we'll put one in on the 60 Silver BE as well.

You can see the original metal, primrose yellow, version and the rattle can painted fibreglas semi-clone. Apologies, but the only photo if have of it installed is in the white, unpainted, protoype form. Jeff's looking into producing more if there's interest. It works well on our yellow 59, and we'll put one in on the 60 Silver BE as well.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>