nichola

Jedi Hopeful

Offline

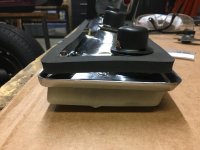

Can anyone recommend a decent gasket for sealing the tail lamp assembly to the body for a TR6? The one I received is a terrible fit (see pics), requiring a LOT of stretching to get it anywhere near where it needs to be. Alternatively, has anyone tried making their own, perhaps using a round foam cord? Thanks for any advice.

While on the subject of rear tail lamps... the replacement bulb holders are also worthless. Better off trying to rescue the originals.

While on the subject of rear tail lamps... the replacement bulb holders are also worthless. Better off trying to rescue the originals.

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>