deuce

Senior Member

Offline

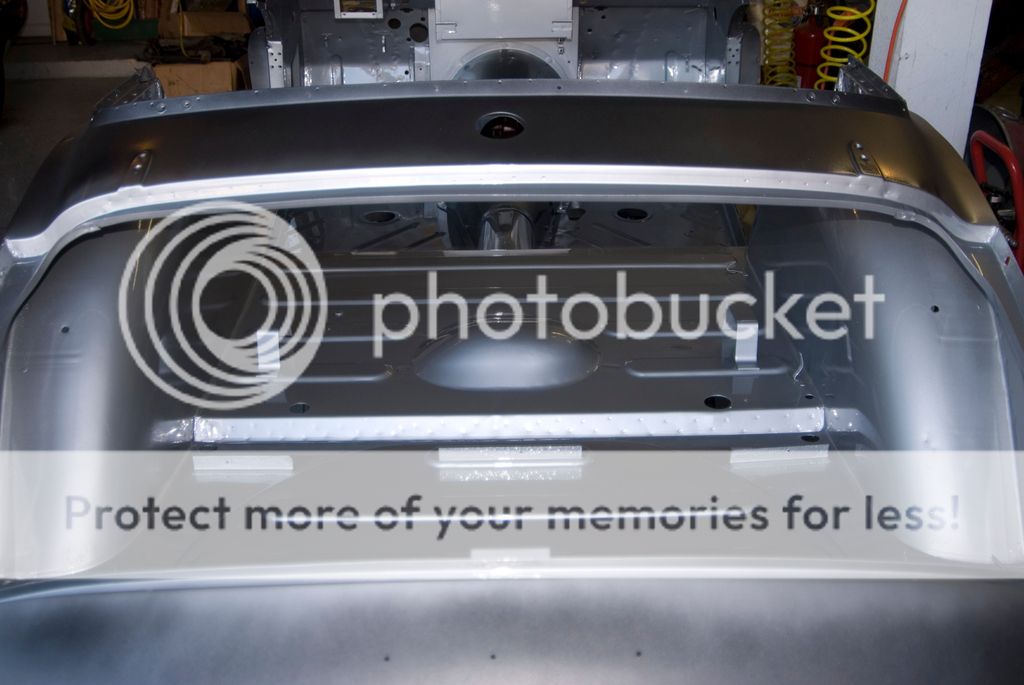

Hello TR3 guys..I am working on the rear shelf of my TR3-a. Have any of you fabricated the differential dome? I have been trying to use the old shelf as a pattern and it's driving me crazy. My brother was a metal fabricator. He's talking about pi times this and dividing by that. There must be an easier way. I saw something in the Roger Williams book but there's little detail. A layout would be great. Advise would be great. Thanks in advance

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>