-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

jack/jackstand placement bj7

- Thread starter Roberte

- Start date

Keoke

Great Pumpkin

Offline

if I want to raise the entire front/rear end of my car where do I place the jack? After car is raised where do I place the jack stands?

Rear end Jack:

Under the pumpkin

Jack Stands:

Under the diff housing at each end.

Front end Jack:

A support must be used with the Jack that covers,protects and spans the front cross member.

Front end Jack Stands:

Under each spring pan

NOTE!!

First set emergency Brake then Jack the front & add Jack stands

Second jack the rear and add Jack stands.

She will be up on all fours now--

Offline

I've used a wooden 2 x 4 under the front cross member. Extend it to the seams in the middle of the main rails.

BTW, if I'm lifting the whole car, I have to do the rear first. If I do the front first, I can't get the jack under the rear. Only those guys with BJ8s with the high rear ends can do the front first.

BTW, if I'm lifting the whole car, I have to do the rear first. If I do the front first, I can't get the jack under the rear. Only those guys with BJ8s with the high rear ends can do the front first.

Offline

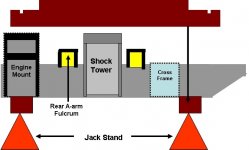

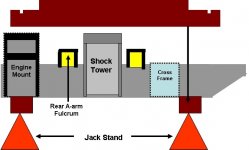

I'll just re-enforce what has already been said. Jack up the back first with a walker undercar jack under the pumpkin. Put a heavy rag on the jack pad to not scratch the pumpkin. Put jack stands under the frame rails about in line with the rear axle. Use a piece of plywood about 3" square between the jackstand and the frame rail. This will help from marking the frame and also help to keep things from slipping around. Put a 2x4 wood under your front crossmember all the way from under one frame rail to the other frame rail. Jack up front with the same jack on the wood. Put Jack stands under the frame rails just behind the wood piece that is across the crossmember. Use small pieces of plywood here as well. Here's some pic that might help to see it.

Attachments

Offline

Jacking up my Healey is a piece of cake compared to some of the race cars, esp. the Ginetta which has long overhangs fore and aft and extremely low ground clearance. This Harbor Freight jack

https://www.harborfreight.com/2-ton...vy-duty-floor-jack-with-rapid-pump-68050.html

makes it all a piece of cake and I can easily raise the front of the Healey, put it on tall jack stands, and still be able to get under the back of the car. BTW I use the crossmembers as jacking points.

https://www.harborfreight.com/2-ton...vy-duty-floor-jack-with-rapid-pump-68050.html

makes it all a piece of cake and I can easily raise the front of the Healey, put it on tall jack stands, and still be able to get under the back of the car. BTW I use the crossmembers as jacking points.

RAC68

Darth Vader

Offline

Hi Robert,

Take a look at the supports I created when working on the frame quite a while ago. These wooden supports allowed for the frame to be raised and held without causing any deformation during the raised by jack or maintained with jack stands. I also used a straight board under each end of the rear cross member in concert with these 2 front supports.

Hope it helps,

Ray(64BJ8P1)

Take a look at the supports I created when working on the frame quite a while ago. These wooden supports allowed for the frame to be raised and held without causing any deformation during the raised by jack or maintained with jack stands. I also used a straight board under each end of the rear cross member in concert with these 2 front supports.

Hope it helps,

Ray(64BJ8P1)

tahoe healey

Yoda

Offline

I fit a hockey puck to my floor jack (they are a hard rubber) to protect the frame and pumpkin. On the front end I attached another hockey puck to a 1/4 inch thick steel slab 12 1/2 inches long (5 inches wide with a 1 inch lip) to fit the front cross frame.

For the rear drive onto two 6 inch wide "ramps". I have screwed two 2 x 6 blocks of wood together (one 24 inches and 28 inches long making a kind of step to drive up) set flush to one end. This gives me 4 extra inches to clear the rear exhaust with my rolling floor jack. I set the floor jacks as above. Don't forget to place a block in each of the front shock "A" frame to prevent the front from hanging. This has always worked for me but every one has their own method.

By the way, used hockey pucks can be had at second hand sports shops for 50 cents US.

For the rear drive onto two 6 inch wide "ramps". I have screwed two 2 x 6 blocks of wood together (one 24 inches and 28 inches long making a kind of step to drive up) set flush to one end. This gives me 4 extra inches to clear the rear exhaust with my rolling floor jack. I set the floor jacks as above. Don't forget to place a block in each of the front shock "A" frame to prevent the front from hanging. This has always worked for me but every one has their own method.

By the way, used hockey pucks can be had at second hand sports shops for 50 cents US.

Offline

....

By the way, used hockey pucks can be had at second hand sports shops for 50 cents US.

One can probably find them lying around for free in Canada.

58 special

Freshman Member

Offline

Years of coaching and 50 years of playing. Ive given away 3 - 5gallon pails recently still find pails full of pucks hidden away in corners.

RAC68

Darth Vader

Offline

WoW, never thought of using Hockey Pucks for jack buffers. Using old puck after cutting a groove for the center frame weld would provide an even better center-positioning reasonably secure support for general purpose quick lifts. However, if you intend to keep the frame in the air with major components (engine, transmission, etc.) still installed, I would suggest you use a more substantial support system (as described above) that locks the frame's main weight carrying sections into proper position and support for an extended lift.

Ray(64BJ8P1)

Ray(64BJ8P1)

Jim 58 BN6

Jedi Trainee

Offline

One can probably find them lying around for free in Canada.

Years of coaching and 50 years of playing. Ive given away 3 - 5gallon pails recently still find pails full of pucks hidden away in corners.

Look under the sofa, I mean chesterfield, cushions as well. They're probably mixed in with loose change...

Lots of constructive info here. I'll add another--I think it's helpful. If the front is jacked up under the frame, even with a two by four or whatever to spread the load, the weight of the wheel and suspension assembly crushes down on the rubber rebound buffers, Moss part no. 031-279. I have replaced the damaged buffers on my car, and should note that Steve G, a regular poster here, has an excellent shortcut for making that replacement on his Web site. I think concern for the buffers is one reason to rest the car weight under the spring pans. Unfortunately, it can be difficult to get a floor jack under them. I have my car in the air right now, and I have padded jack stands under the frame and jacks under the spring pans. You can also put a wood block under the pad-like portion of the upper wishbone to prevent buffer compression.

Offline

.... You can also put a wood block under the pad-like portion of the upper wishbone to prevent buffer compression.

Yes, a 2" block of wood will keep the front suspension in it's normal running position.

Offline

The concern to protect the rubber bumper on the front suspension is a worthy concept. But beyond the concern about the rubber, the front suspension can hang fully dropped, completely assembled for an indefinate amount of time. I've done it many times and in the most recent episode my BJ7 sat on those jack stands during body reconstruction, with engine and transmission in place, with the front suspension in place for over 4 years. There is no damage, the car tracks and steers perfectly.

Attachments

red57

Jedi Knight

Offline

They put the rubber buffers there for a reason, and that means when you jack it up they are doing what they are supposed to do - prevent metal to metal contact. I too have had my car on stands for long periods and never found them damaged, or anything misaligned. Beyond that, they are really easy to replace if needed.

Offline

I have a jack saddle made by Lin Cline (sadly no longer with us) that encases the crossmember (front or back) preventing dents, etc. Go here and scroll down to post #10 for some photos and discussion:

https://www.britishcarforum.com/bcf...ealey-jacking-points-and-jack-stand-placement

https://www.britishcarforum.com/bcf...ealey-jacking-points-and-jack-stand-placement