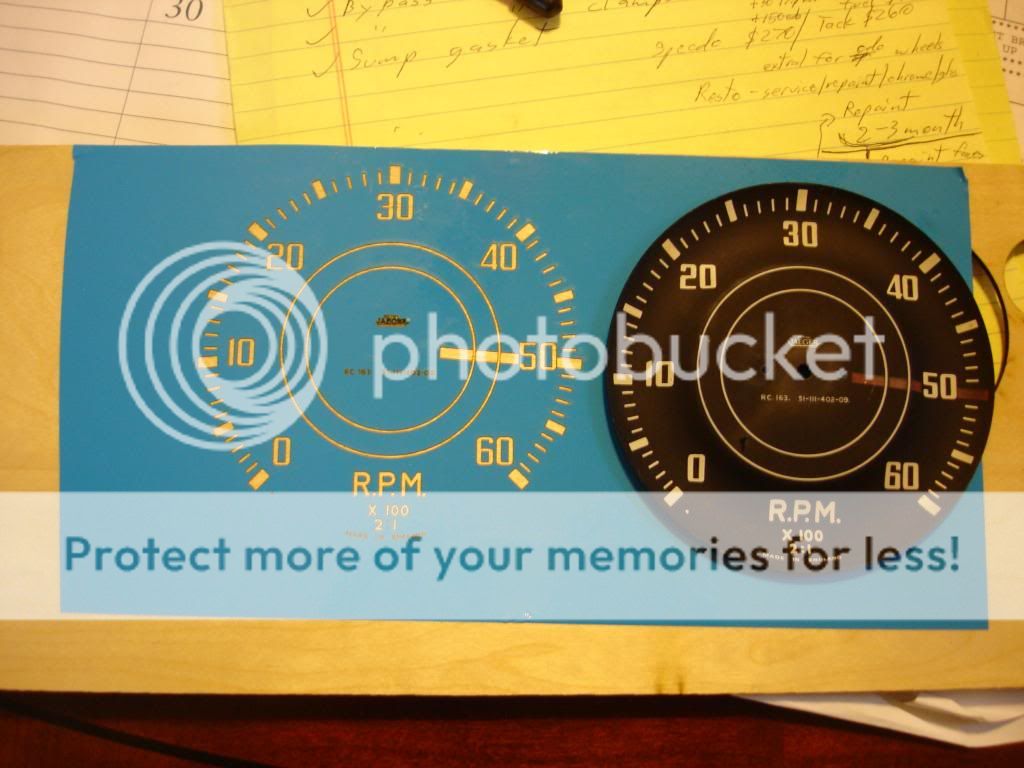

At this point, you have a good view of the faces, and have cleaned them with a soft brush. If you are lucky, they will be good and re-usable as-is. You can skip ahead to where I rebuild them and calibrate. If you are like me, and not so lucky, the following many posts will be about restoring the faces, so I can get to the rebuilding and calibrating. So, here goes the face resto...

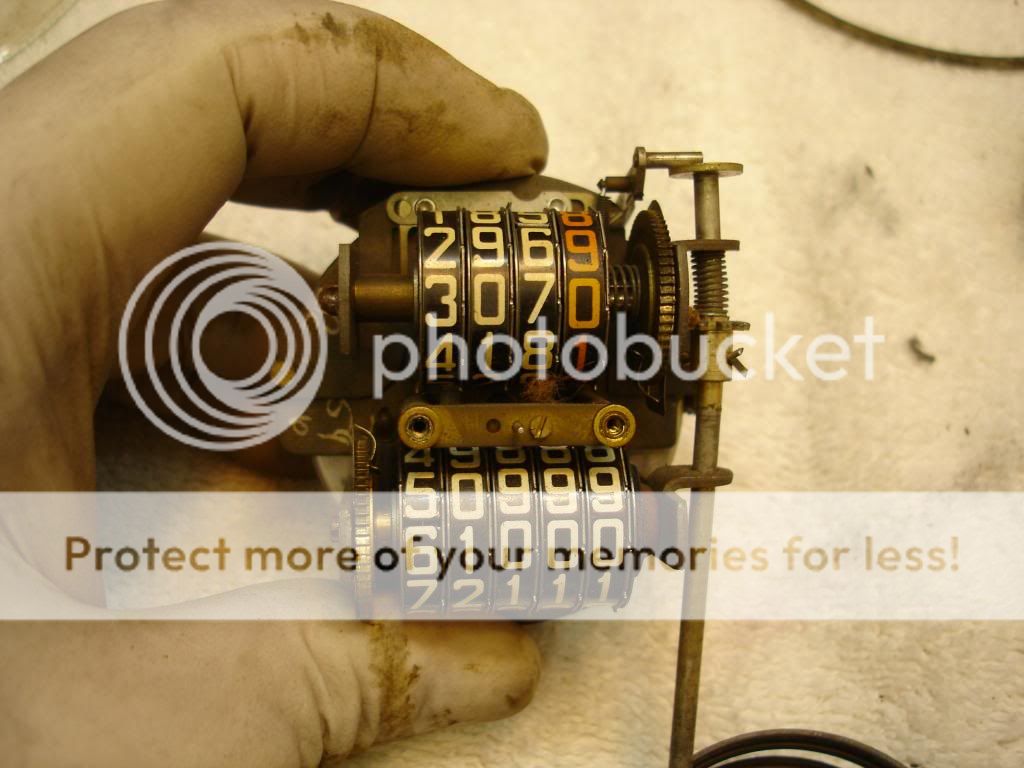

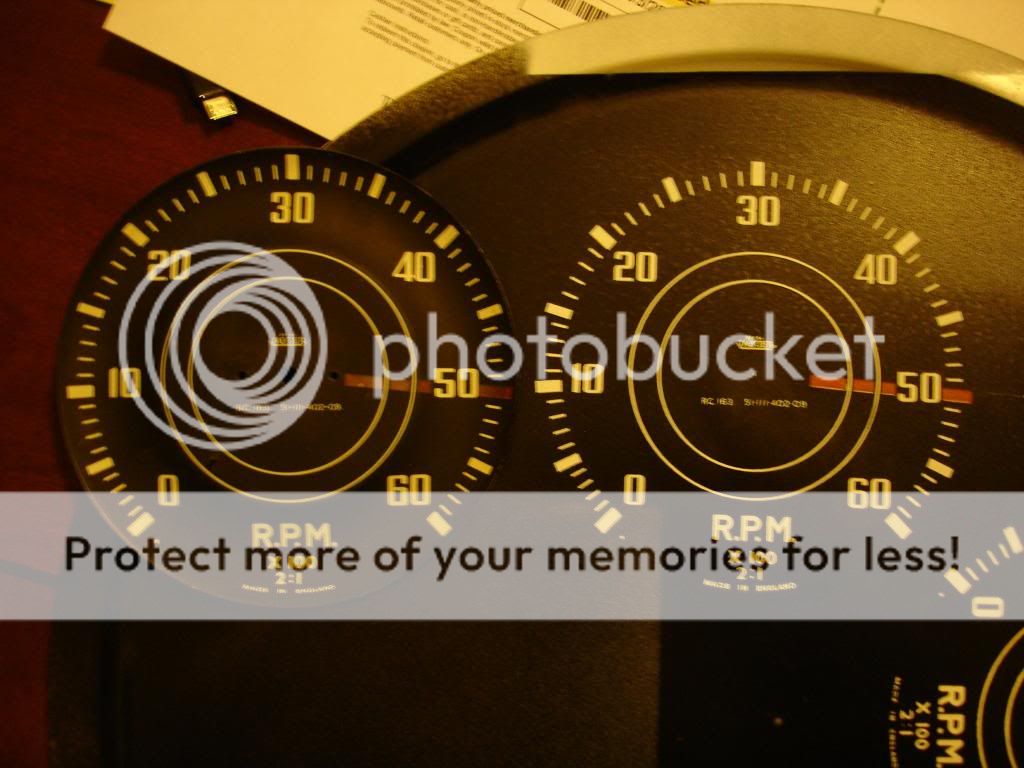

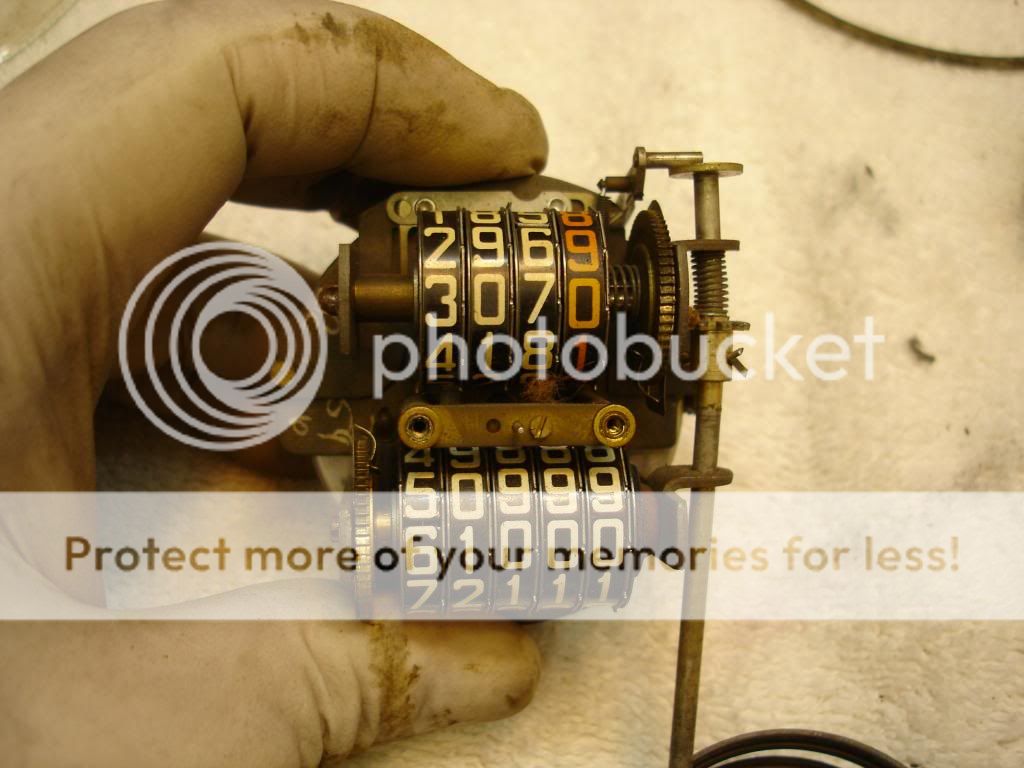

The tach and speedo are built under similar principals. A magnet spins, which imparts a force on an aluminum spinner. The needle is attached to the spinner, and a small spring brings the needle back to zero. The speedo is complicated by the addition of the odometer.

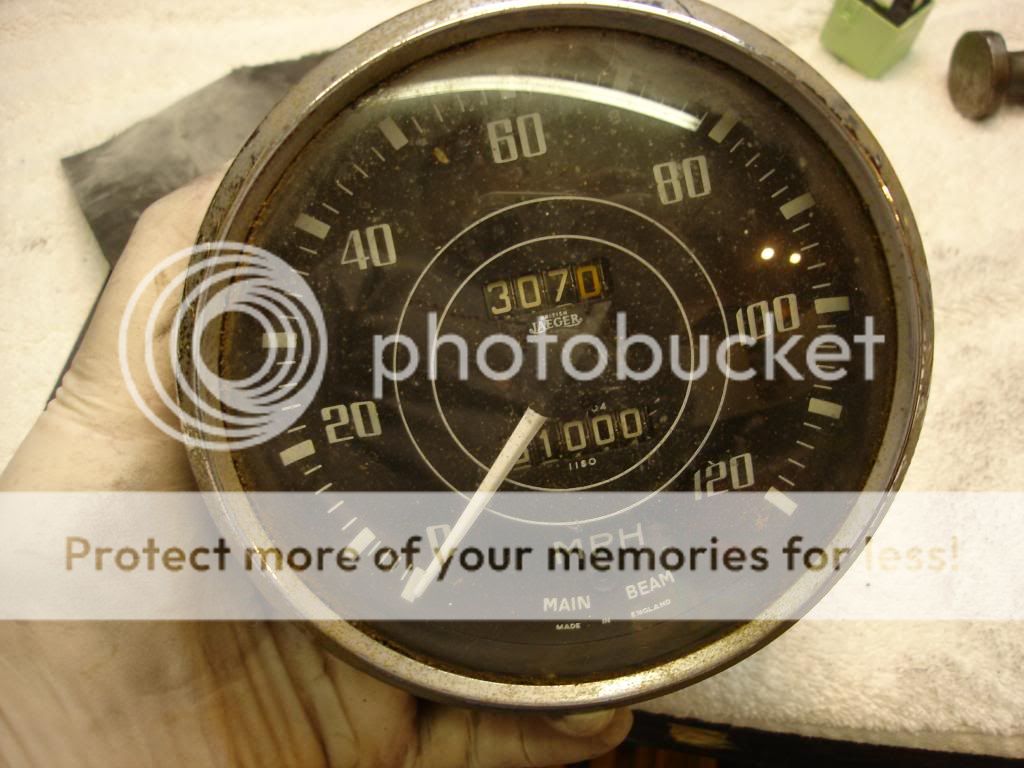

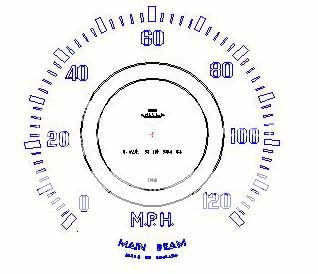

2 screws remove the assemblies from the housing. Remove the needle by holding the aluminum disc in the rear as you gently twist the needle away from the "0" and pull. Do not force...it comes off easily if you are doing it right. Now remove the face by removing 2 small jewelers screws. Here is what I had on the speedo, showing the small light for the high beam:

The light comes out by gently punching the back while supporting the front:

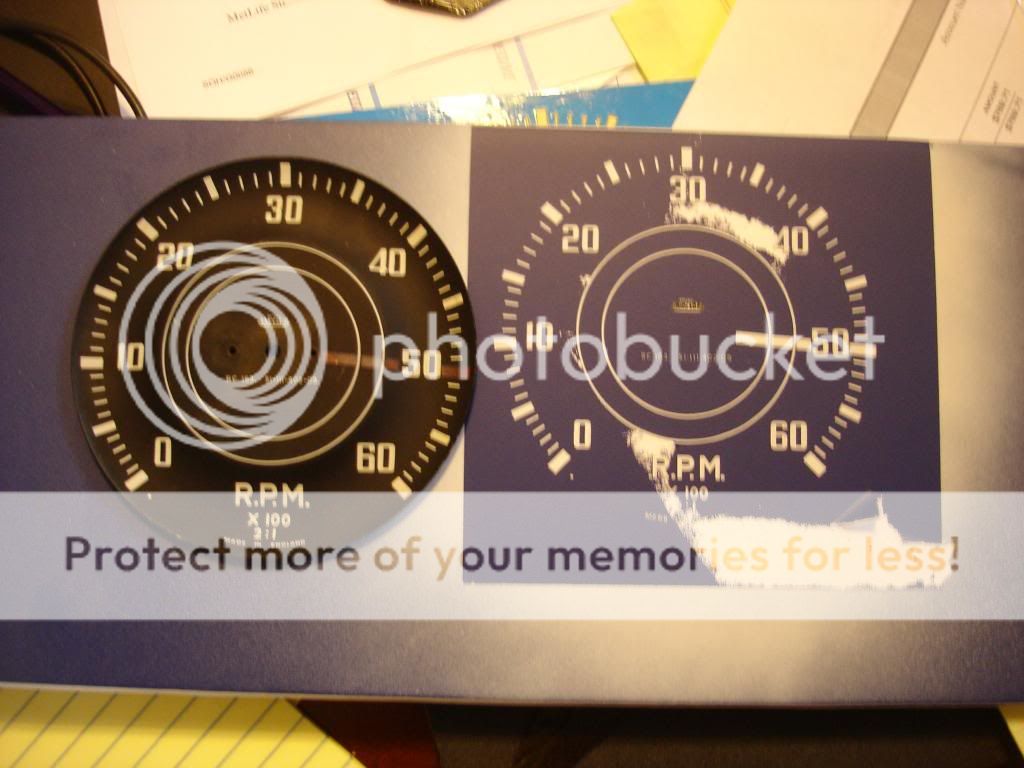

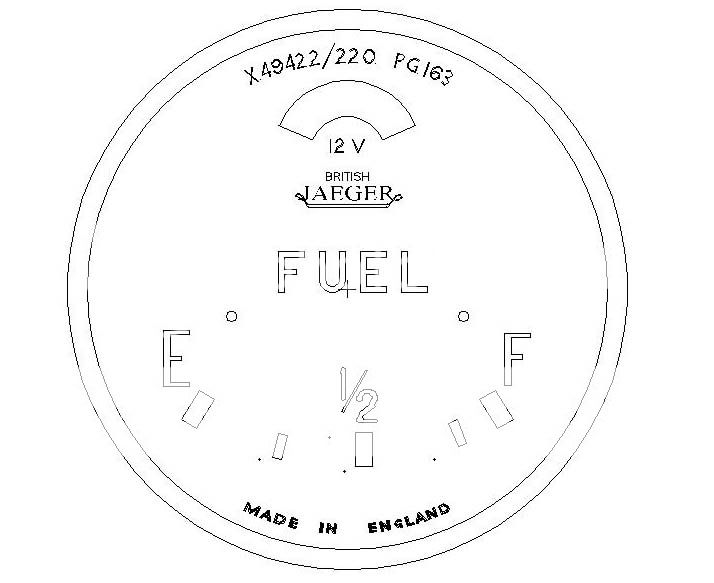

Here is the back of a typcial gage. Note that there is a bit of overspray around the edges. This tells me that the factory painted the white first, and then just flipped it over and sprayed the black on the front, with little or no masking.

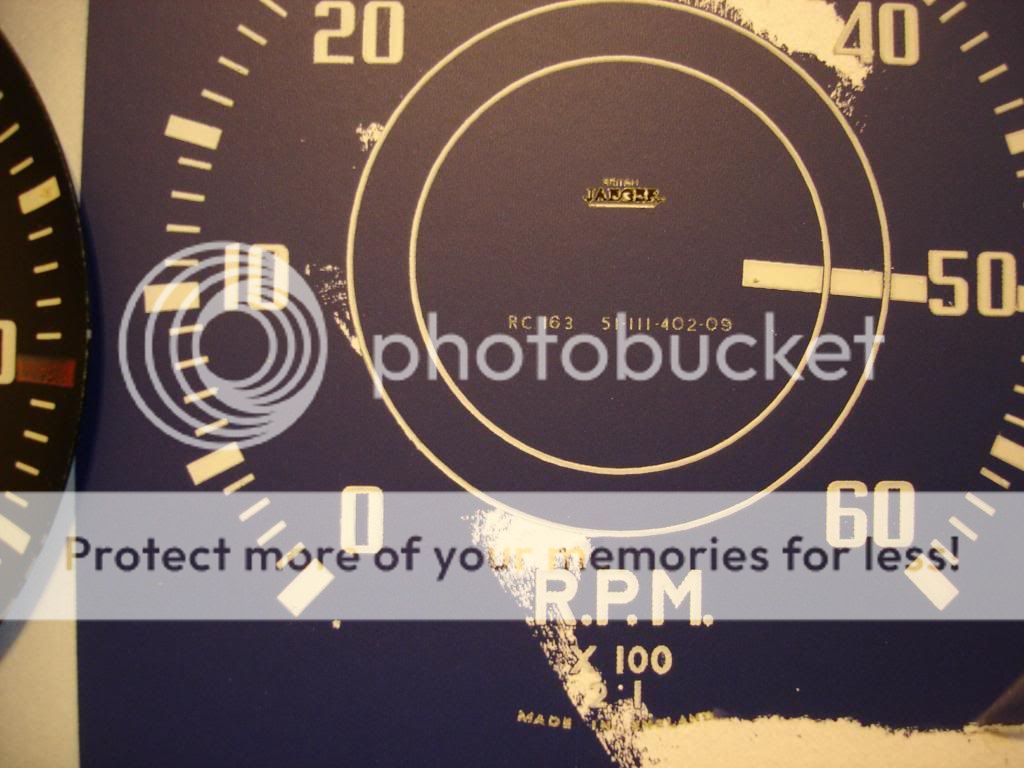

I photo's the faces in very fine detail. It will be the last time I get a chance to see them as...here is the sanded tach face:

There is no turning back now! My only fear in repaintinf is that the mask will pull up the base paint. I made sure to get a very rough surface to bond the paint to, to at least give it a fighting chance of staying on.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>