So im working on restoring an early midget. This car has a bit more rot than i thought it would. looks like im going to be doing the inner sill, rocker, a post, and floors. The question is where should i start? everything is connected to each other. i was thinking that inner sills would be first then a-post to check the door gap, then the outer rocker panel followed by the a post skin. then when all this is done on both sides do the floors. does this sound about right? I have heard about tweaking the door gaps by jacking up under the transmission tunnel with the car sitting on jack stands. do you get the door gap where you want it then weld the inner sill? or would you all ready have the inner sill welded up and lock the door gap in when you weld the rocker? im just trying to wrap my head around this. i know i have allot of work ahead of me and i just have to do it one step at a time, i just want to get those steps in the right order so i don't have problems later.

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

inner sills, outer sills, a post...where to start?

- Thread starter seanb

- Start date

Offline

A couple of thoughts - Whatever you do, brace the car really well. Adjusting the door gap by bending the car probably doesn't bode well for the future of the car - don't forget you will never get "Honda" gaps.

Your order sounds pretty good - inner, post, outer. (I don't do body work though so let someone else confirm)

I don't know if you are a welder but another thought is another body. It might be worth having your VIN plates <ahem> fall onto another body. There seem to be a few around,

Don't know how solid this is

https://asheville.craigslist.org/cto/2866965838.html

or

https://asheville.craigslist.org/cto/2821625190.html

even this might be worth it if you cost it out

https://asheville.craigslist.org/cto/2831007572.html

Your order sounds pretty good - inner, post, outer. (I don't do body work though so let someone else confirm)

I don't know if you are a welder but another thought is another body. It might be worth having your VIN plates <ahem> fall onto another body. There seem to be a few around,

Don't know how solid this is

https://asheville.craigslist.org/cto/2866965838.html

or

https://asheville.craigslist.org/cto/2821625190.html

even this might be worth it if you cost it out

https://asheville.craigslist.org/cto/2831007572.html

G

Guest

Guest

Guest

Offline

I'm with Jp, lotsa time and $$$ to do all that.

Four years two months and I don't even want to know how much in tools and parts

https://www.spritespot.com/gallery/1960-bugeye-refurb

https://www.spritespot.com/gallery/1960-bugeye-refurb

well guys the deal is i have a completely custom front suspension welded in the car now. i bought it that way and specifically for that reason. I had pondered with cutting out the suspension and moving it to another car but i think i will just repair the car i have. its an early midget and that's what i wanted anyways.

Mark-that photo album is full of great information. you must be a master at welding and bodywork by now! funny thing is my car also has a replacement rockers pop riveted over the old rockers just like your car had. mine also has holes in the floor with steel pop riveted over to patch it. i guess the guy didn't have a welder.

Mark-that photo album is full of great information. you must be a master at welding and bodywork by now! funny thing is my car also has a replacement rockers pop riveted over the old rockers just like your car had. mine also has holes in the floor with steel pop riveted over to patch it. i guess the guy didn't have a welder.

RickB

Yoda

Offline

When you have the car you want you know it.

That's part of what makes it "your car", and you wanted to brush up on the welding anyway right?

It will add to the sense of accomplishment when it's all done.

Plus there's no better way to really know your car than to rip it apart and put it back together.

Boy, look who woke up on the bright side this morning!

That's part of what makes it "your car", and you wanted to brush up on the welding anyway right?

It will add to the sense of accomplishment when it's all done.

Plus there's no better way to really know your car than to rip it apart and put it back together.

Boy, look who woke up on the bright side this morning!

Your new nick name is SunshineRickB said:When you have the car you want you know it.

That's part of what makes it "your car", and you wanted to brush up on the welding anyway right?

It will add to the sense of accomplishment when it's all done.

Plus there's no better way to really know your car than to rip it apart and put it back together.

Boy, look who woke up on the bright side this morning!

HAN8L1965

Jedi Warrior

Offline

Well I did the same job you are inquiring about but just the driver floor pan. As was suggested brace the car well before removing anything, I actually mounted mine to a platform to keep it as square as possible. Eastway and some others sell a spot weld remover which is a special drill bit, you will go through afew of these but they make the job simpler and easier. You will find that the Inner sills are the true back bone of the car, I bought all my metal from VB and for the most part it fit pretty good but you will have to do adjustments and cutting. If you can get away with doing just the lower A Posts that will give you a little relief, you will most likely have to replace the door hinge, you pretty much have to put the A Post back together skin and all at the same time to get it right. The outer sill is the least of your worries. Use your doors as guides as necessary to make sure thinks are going back together correctly.

Good luck

Mark

Good luck

Mark

G

Guest

Guest

Guest

Offline

seanb said:well guys the deal is i have a completely custom front suspension welded in the car now. .

~Oh~, ~that car~. The red one the suspension guy had. Seen it at the X.

bgbassplyr

Darth Vader

Offline

Harbor Freight also has the spot weld remover bits.

bgbassplyr

Darth Vader

Offline

There are many places where you can't get a clamp to pull two pieces of metal together, so I tend to rivet it all together...then...weld.

G

Guest

Guest

Guest

Offline

Sean, show 'em what ol' boy did.

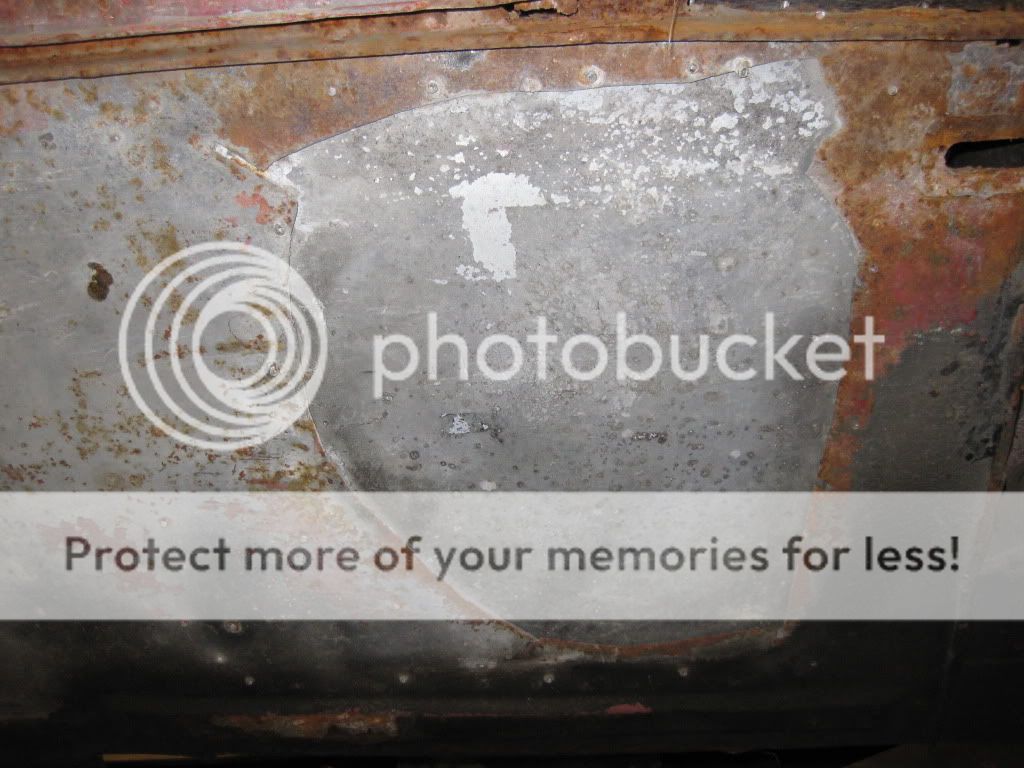

previous attempt at a "restoration" i guess. the entire replacement rocker has been riveted to what was left of the old rocker. you can also see in the pic rusty holes in the floor pan "patched" with thin steel and aluminum rivets. guess the guy didn't think any of this was structural.

G

Guest

Guest

Guest

Offline

Hahaha, no, not that, the suspension mods.

-New Wilwood's tall spindles

-New Heidt's Superide II narrowed tubular upper and lower control arms.

-New Afco double adjustable coil over shocks with 4" stroke

-New 10.5" vented rotors with Wilwoods four piston calipers

-New Schroeder torsion bar

-New modified Triumph Spitfire quick steer rack 2.5 turns lock to lock.

-The complete suspension hub to hub is only 1.5" wider than the stock front end was.

that was copied directly from the add when the car was listed for sale. the PO worked for Heidts (they do muscle car suspension) and had an engineer friend design the suspension. Now he works for speedway. it really is beautiful, the coil over and top A arm brackets are tig welded. The a arms are tig welded, looks like the same guy did all the tig work, maybe a heidts welder but im just speculating. if i can get the rest of the car up to snuff i think it will be a sweet ride!

-New Heidt's Superide II narrowed tubular upper and lower control arms.

-New Afco double adjustable coil over shocks with 4" stroke

-New 10.5" vented rotors with Wilwoods four piston calipers

-New Schroeder torsion bar

-New modified Triumph Spitfire quick steer rack 2.5 turns lock to lock.

-The complete suspension hub to hub is only 1.5" wider than the stock front end was.

that was copied directly from the add when the car was listed for sale. the PO worked for Heidts (they do muscle car suspension) and had an engineer friend design the suspension. Now he works for speedway. it really is beautiful, the coil over and top A arm brackets are tig welded. The a arms are tig welded, looks like the same guy did all the tig work, maybe a heidts welder but im just speculating. if i can get the rest of the car up to snuff i think it will be a sweet ride!