Hi Everyone. I have done this job on multiple spitfires and even a TR4 by myself. Here is whats going on. I pulled the gearbox from my TR6 and replaced the clutch/had flywheel remachined/new pressure plate, etc. Clutch alignment tool worked well. Now I am having a horrible time getting the gearbox to mount to the motor. I pulled the gearbox from the inside of the car. Should I pull the driveshaft? It is just so awkward and difficult to handle. I may have to enlist some friends but I would rather do it myself. I know TRF has some pins that go on the sides of the bellhousing to help align things. PLEASE HELP!!!

-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR6 Help installing the Gear Box 1972 Triumph TR6

- Thread starter spicybbq

- Start date

alanjohnturner

Jedi Trainee

Offline

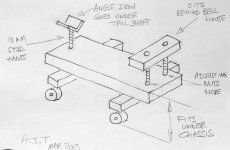

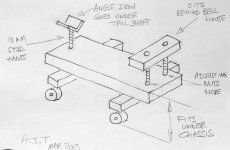

I have a wooden trolley made like this. It slides under the car and then you fit two adjustable jack-screws.

You can set the gearbox height exactly and then just run it up and mate the input shaft.

You can concentrate on rotating the spines so they slip in.

Break off, have a beer, and come back and the gearbox is waiting there for you.

You can set the gearbox height exactly and then just run it up and mate the input shaft.

You can concentrate on rotating the spines so they slip in.

Break off, have a beer, and come back and the gearbox is waiting there for you.

TR3driver

Great Pumpkin - R.I.P

Offline

Uhm, if you cannot get the gearbox mated, how do you know the alignment tool worked well? I've not tried the TR6 tool, but the TR2-4 tool I got from Moss was nearly useless. After several hours of trying to get things mated, I pulled the gearbox back out and felt down the hole with my fingers, to discover that the plate was significantly off-center to the crank. When I recentered just by feel, it all slid together easily.Clutch alignment tool worked well. Now I am having a horrible time getting the gearbox to mount to the motor.

Now I always use an old input shaft. The fit is obviously much more precise than the tool, as the tool would wobble around even with the pressure plate bolts tight, while the input shaft will only move by a few .001".

Geo Hahn

Yoda

Offline

Similar to Alan's trolley, I have used a HF Transmission Jack.

I have also had occasion to slip a metal rod (an old jack handle) under the tailshaft so it is supported yet can be rolled for & aft.

Finally, I made some headless bolts to temporarily screw into the engine side to guide the bellhousing home:

All these were on a 4-cyl gearbox -- not all were used each time, just a matter of what seemed right for the job at hand.

I have also had occasion to slip a metal rod (an old jack handle) under the tailshaft so it is supported yet can be rolled for & aft.

Finally, I made some headless bolts to temporarily screw into the engine side to guide the bellhousing home:

All these were on a 4-cyl gearbox -- not all were used each time, just a matter of what seemed right for the job at hand.

mrv8q

Luke Skywalker

Offline

So, a couple questions about spicybbq's situation. Generally, do you raise the car on jackstands high enough to clear rolling the now-unmated gearbox on a trolley under the car and out? Or do you leave the car on it's tires, drop the gearbox on a trolley, and then horse it out thru the interior?

How do you support the engine whilst the gearbox is out? 2X4 across both fenders, and a chain from the rear engine hoist bracket to the 2X4?

Thanks for the opportunity for letting me use whilst....

How do you support the engine whilst the gearbox is out? 2X4 across both fenders, and a chain from the rear engine hoist bracket to the 2X4?

Thanks for the opportunity for letting me use whilst....

If you haven't done so, join the Portland Triumph Owners Association, many members would be glad to help or advise. I have found that the secret to getting the trans. to mate with the engine is keep the gap even all the way around as the trans is moved forward. The dowels also help to support the trans and prevent damage to the clutch disc and imput shaft. As mentioned, a trolley jack is helpful to adjust the heighth and forward movement. Raising the engine as high as possible may also help. R&R the trans. is about a 4 Chiropractor visit job, depending on age, strength, and if an OD is attached. Berry

I have the front and rear of the car on jackstands. I am not supporting the engine but I do have a cherry picker I could use to support it. I know the alignment tool worked because it fully inserts and the end piece fits into the bushing in the flywheel. I confirmed this. I like Alan's diagram. I may try to build one of those units.

poolboy

Yoda

Offline

Did you jack up the engine enough to make it level again after having removed the gearbox ?

Do that; have the 2 alignment dowels on the engine plate inplace and a hand on the tranny's mainshft flange to align the mainshaft spilines with the clutch and some grunting. ..that and a 3rd hand really helps .

Do that; have the 2 alignment dowels on the engine plate inplace and a hand on the tranny's mainshft flange to align the mainshaft spilines with the clutch and some grunting. ..that and a 3rd hand really helps .

Offline

OK, this is not the finesse precise intellectual response, but the garage ape approach, but has worked well for me when I have put trannys in by myself, usually pretty easy to get the first part started, but then many times hangs up, but get it started and aligned as well as possible. At this point put a thick towel or some padding on the emergency brake, sit down on the e-brake, put your feet on the flanges on each side of the bell housing of the tranny, and your hands on the end of the tailshaft, from this position you can alter the angle of the tranny slightly and also turn the splines by turning the flange on the end of the tranny. Of course you don't want to get to crazy, but with a little up and down and side to side with some forward pressure from the legs, and you can usually find the sweet spot and slide it the rest of the way in.

Make sure the fork pins are still in the groove on the throw-out bearing sleeve. You can put a piece of wire around the fork pulling it back so the bearing sleeve does not slide forward and disengage the pins. Make sure you are able to pull the wire back out before bolting things up. If this happens you will not be able to close the 1.5" gap between the engine and the bell housing, which is a good thing. As mentioned above make sure you jack up the engine so it sits level with the trans.

Offline

I used a small bottle jack under the engine to help align the shaft in addition to the alignment dowels. It is a job, there is no doubt about it, but you will get it.

Last edited:

RomanH

Jedi Knight

Offline

To add to all of the sound advice above another little trick that helps, along with having the rear of the engine supported, is it may help to put the trans in gear and rotate the output flange to try and get the input shaft splines to align with the splines on the clutch. All while applying forward pressure on the trans.