TOC said:If the .086" is down between the shims and third gear, too much. The only other thing I can think of to look for is tapered (worn) engagement dogs on third gear. These are the second set of "teeth" that the synchro ring actually engage. On other marques, see high-mileage tansmissions where those are worn on one (or maybe both) sides to a taper pointing towards the synchro.

Get a good light and maybe a magnifying glass, and look at them, comparing shape to 4th, second and first teeth.

Just in case.

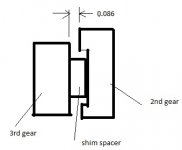

.086" is the gap between the rear face of the 3rd speed gear and the front face of the 2nd speed gear. See attached image of what I am talking about. You will notice that 2nd speed gear has an undercut in which the shim is inset into it.

I took a look at the dogs and don't see any issue, all look the same. This transmission was rebuilt by a local shop about 5000 miles ago or so.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>