Luke_Healey

Jedi Trainee

Offline

I popped off my hubcaps to examing my wheel bearings tonight and I'm at a loss as to what to do.

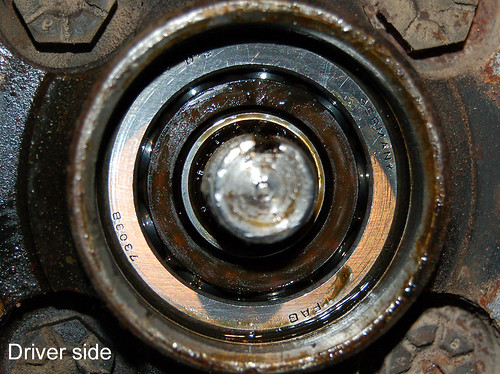

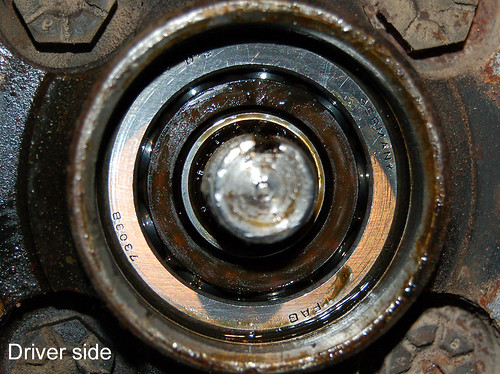

The driver's side outter bearing seems to be installed backwards to me (thick face of outter bearing facing outward..)

Also, on both sides, the castleated nut was only finger tightened and then backed off to the nearest available castle dip. When I tightened each nut to 45 ft/lb, the wheels would not spin freely. So what's the story with that? I have not verified that my car has it's spinder spacers in there yet. Do the bearings pull out easily, or will I have to remove the brake calipers to get an eye on the interior of the hub?

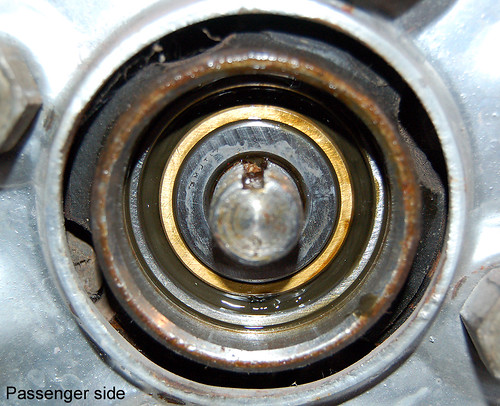

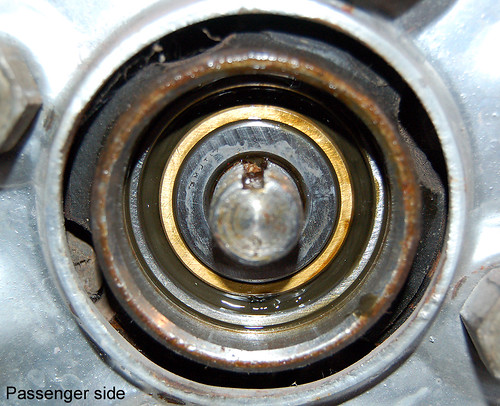

My next observation was that the bearings are not even the same. So apparently one side of the car has been serviced at a different time than the other. They each had a spacer/washer thing between the nut and bearing. I removed those for these photos to show the inner races.

Driver's side:

Passenger's side (wheel still on hub):

So, I'm looking for opinions on any immediate avenues to persue. I'd like to ensure that the car quits shaking at about 53mph and becoming very unstable in a corner. The tie rod ends are tight, as is the steering rack (seemingly.) Do I keep using these bearings? Is there any way to tell if they are bad? Why do they bind up at proper torque spec?

The driver's side outter bearing seems to be installed backwards to me (thick face of outter bearing facing outward..)

Also, on both sides, the castleated nut was only finger tightened and then backed off to the nearest available castle dip. When I tightened each nut to 45 ft/lb, the wheels would not spin freely. So what's the story with that? I have not verified that my car has it's spinder spacers in there yet. Do the bearings pull out easily, or will I have to remove the brake calipers to get an eye on the interior of the hub?

My next observation was that the bearings are not even the same. So apparently one side of the car has been serviced at a different time than the other. They each had a spacer/washer thing between the nut and bearing. I removed those for these photos to show the inner races.

Driver's side:

Passenger's side (wheel still on hub):

So, I'm looking for opinions on any immediate avenues to persue. I'd like to ensure that the car quits shaking at about 53mph and becoming very unstable in a corner. The tie rod ends are tight, as is the steering rack (seemingly.) Do I keep using these bearings? Is there any way to tell if they are bad? Why do they bind up at proper torque spec?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>