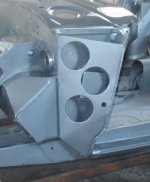

The rear shock tower brace is impressive engineering. Presumably, it will solve the recurring problem--if you drive your car enough, you'll have it--of the rear shock bolts working themselves loose. IMO, putting just a couple bolts in shear to secure the rear shocks--with no bracing--in an application with major shear forces is one of worst engineering faux pas on our cars. I've solved the front shock bolts working loose problem on my cars, but I just spent a couple hours replacing the standard split lock washers on both my Healeys' rear shocks with Nord Lock washers, secured with blue threadlocker. If that doesn't work I'm out of ideas for a permanent fix, and will just have to remember to re-torque those bolts every year or so, a job made more onerous due to the difficulty of getting a socket on the bolts and nuts (my BN2 has two 6V batteries and the trays make it impossible to get anything but an open end wrench on the nuts, and the cutouts for the bolt heads are borderline too small).

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>