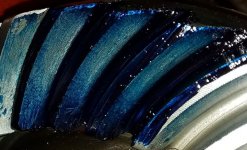

I'm currently rebuilding the differential on my 3A. Never done one of these, and would appreciate some help interpreting the gear markings. This is the first cut with original shims and exact Timken replacement bearings except for the pinion head (used a 3188 instead of a 3188s). Pinion pre-load and backlash were in spec at 18 in-lbs and 5-mils respectively.

Drive

Coast

Drive

Coast

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>