Offline

Hi all,

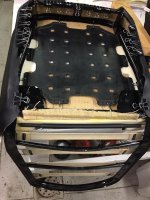

Just curious what the collective wisdom is for using contact adhesive on open cell foam. I am rebuilding the seats on my TR4A, and am using Weldwood high temp Landau adhesive https://www.dap.com/dap-products-ph/weldwood-landau-top-trim-high-heat-resistant-contact-cement/ at the suggestion of several folks here as well as on a hot-rodding forum. I am brushing, not spraying it on.

I have made a few trial bonds with the stuff and am struggling to get a strong bond... I am not getting an "instant" bond, and am able to pull apart the pieces a few hours after assembly. Some seem better than others, but none are "strong".

Questions

1. How thick should I spread the stuff? Right now I am putting down one coat on the foam followed immediately by a second coat. Should I put one coat, let it soak in and cure (~10 minutes), and then a second coat?

2. I am using a foam brush - should I use a bristle brush to apply more adhesive?

3. How important is clamping? When I assemble the seat, it may be difficult to get a strong "clamp" while not distorting the thick foam and seat cover.

Thoughts and suggestions are appreciated!

Thank you,

Just curious what the collective wisdom is for using contact adhesive on open cell foam. I am rebuilding the seats on my TR4A, and am using Weldwood high temp Landau adhesive https://www.dap.com/dap-products-ph/weldwood-landau-top-trim-high-heat-resistant-contact-cement/ at the suggestion of several folks here as well as on a hot-rodding forum. I am brushing, not spraying it on.

I have made a few trial bonds with the stuff and am struggling to get a strong bond... I am not getting an "instant" bond, and am able to pull apart the pieces a few hours after assembly. Some seem better than others, but none are "strong".

Questions

1. How thick should I spread the stuff? Right now I am putting down one coat on the foam followed immediately by a second coat. Should I put one coat, let it soak in and cure (~10 minutes), and then a second coat?

2. I am using a foam brush - should I use a bristle brush to apply more adhesive?

3. How important is clamping? When I assemble the seat, it may be difficult to get a strong "clamp" while not distorting the thick foam and seat cover.

Thoughts and suggestions are appreciated!

Thank you,

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>