Hawkscoach

Jedi Hopeful

Offline

gentlemen,

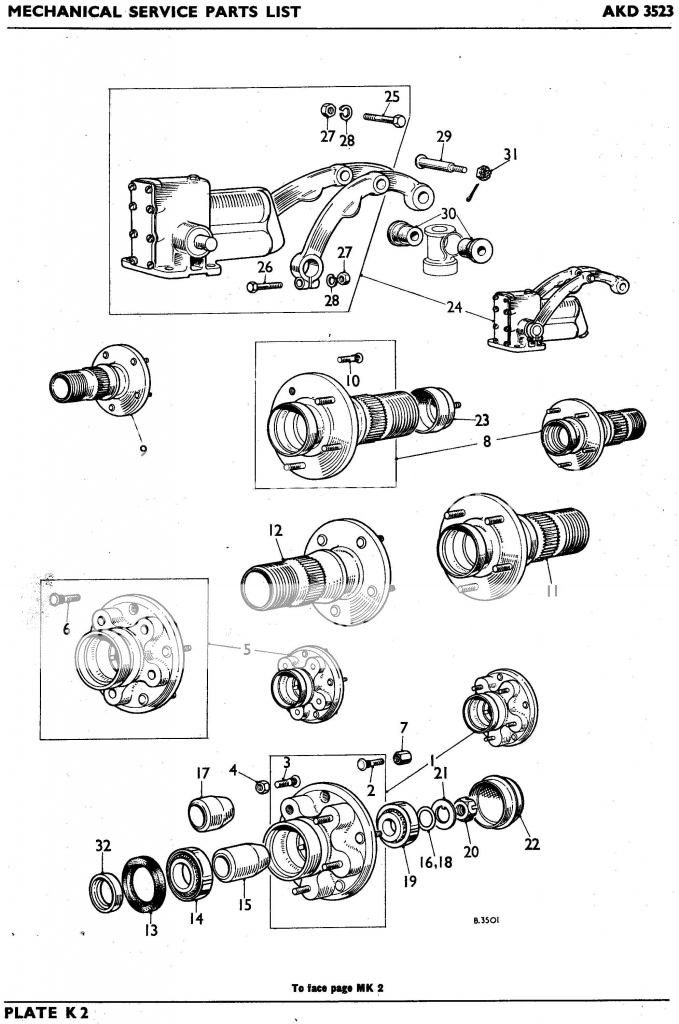

I was able to remove the dust cover (thanks to some previous advice from this site) using a small block of wood with a hole drilled through the center and a nut/bolt, some careful prying and out she came. guess i was lucky with this side. the cotter pin is a pain to remove, however, with some careful patience, it came out. I have NO IDEA how to put another back in? Anyway, my question is; to remove the nut inside, is this a reverse thread? or normal direction? It is tight and I didn't want to force it so I put it down last night and seek your direction..........thanks in advance.

Doug

I was able to remove the dust cover (thanks to some previous advice from this site) using a small block of wood with a hole drilled through the center and a nut/bolt, some careful prying and out she came. guess i was lucky with this side. the cotter pin is a pain to remove, however, with some careful patience, it came out. I have NO IDEA how to put another back in? Anyway, my question is; to remove the nut inside, is this a reverse thread? or normal direction? It is tight and I didn't want to force it so I put it down last night and seek your direction..........thanks in advance.

Doug

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

. The trick with the split pin is to make sure that the length is right to allow you to just spread it with a screw driver just below the nut.

. The trick with the split pin is to make sure that the length is right to allow you to just spread it with a screw driver just below the nut.