-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A Body Restoration - Inner Sill Replacement

- Thread starter Joel M

- Start date

charleyf

Luke Skywalker

Offline

I agree with David. Your No. 7 --repairing the dog leg panel needs to wait until the B post is welded onto the frame. In fact to make it easier on yourself you will need to open that dogleg panel up to access the weld on the rear side of the B post.

On my first inner sill replacement, I only had to do one side. Instead of totally removing the tub from the frame. I removed the frame to tub bolts on the affected side and loosened the frame bolts on the other side. I also used interior supports as well. I was able to lift the body off the frame a few inches on the affected side while leaving the body resting on the frame on the other side. My advantage was that I did not want to allow the body to get distorted. I was successful on that point but it was a bit more difficult.

--I would only remove and replace one sill then move to the second side and remove and replace that sill.

Prior to welding the A and B posts to the sill put the door on the body and align the rear edge of the door with the Body.

Take a good look at the rear door edge before you take the car apart. You may or may not be able to improve an existing bad fit. But if it fits poorly now you will at least know that.

On my first inner sill replacement, I only had to do one side. Instead of totally removing the tub from the frame. I removed the frame to tub bolts on the affected side and loosened the frame bolts on the other side. I also used interior supports as well. I was able to lift the body off the frame a few inches on the affected side while leaving the body resting on the frame on the other side. My advantage was that I did not want to allow the body to get distorted. I was successful on that point but it was a bit more difficult.

--I would only remove and replace one sill then move to the second side and remove and replace that sill.

Prior to welding the A and B posts to the sill put the door on the body and align the rear edge of the door with the Body.

Take a good look at the rear door edge before you take the car apart. You may or may not be able to improve an existing bad fit. But if it fits poorly now you will at least know that.

I would be prone to leave the tub on the frame and crib/block and shim one side up at a time, giving enough room to get the sill in place. I like Charley suggestion about putting the doors on before you go any further to see what you started with and yes the B post side is the complicated side also. The A post side uses the inner kick panel like a straightedge; plus on the front section of the tub some sheet metal hangs down below the inner sill proving a stopping point to set the front , so the back length should be close enough also.

The next problem is do the out-riggers on the tub/floor line up with the out riggers on the inner sill.-- They should if made correct-- I used 8 inch drift pins and dropped them down from the top to insure the 2 would fit onto each other. Again, I found this easier by leaving the tub on the frame by lifting one side at a time, but again I had the floor out and put the floor in after the sill—I do not know how it would work with the floor in place; on the other hand, I can how leaving the floor in could be helpful because having the floor in the tub is held in the front and back with the floor ends the tub would not twist.

Looking good keep posting

The next problem is do the out-riggers on the tub/floor line up with the out riggers on the inner sill.-- They should if made correct-- I used 8 inch drift pins and dropped them down from the top to insure the 2 would fit onto each other. Again, I found this easier by leaving the tub on the frame by lifting one side at a time, but again I had the floor out and put the floor in after the sill—I do not know how it would work with the floor in place; on the other hand, I can how leaving the floor in could be helpful because having the floor in the tub is held in the front and back with the floor ends the tub would not twist.

Looking good keep posting

I did not consider the welds on the back side of the B-post when thinking through the process. Is there a way to gain access other than completely cutting out the lower quarter panel? I was planning on removing just the rusted out section, but that would not give me access to welds. If I have to cut out a significant portion, I think I would order a new one and cut out a repair panel to weld in place.

There are a lot great suggestions in this thread. I will definitely check the doors before I get started to understand the current condition. And I like the idea of leaving the tub on the frame. I may give it a try. I guess I can always remove it to finish the job if it doesn't work.

There are a lot great suggestions in this thread. I will definitely check the doors before I get started to understand the current condition. And I like the idea of leaving the tub on the frame. I may give it a try. I guess I can always remove it to finish the job if it doesn't work.

charleyf

Luke Skywalker

Offline

First the dogleg piece I bought was a VERY poor fit. I only used the very bottom of it , which is about the same size that you are missing some metal. Even at that the bottom took a lot of reworking to fit. Bought it from TRF and they alerted me that it was a poor reproduction. They may well now have something better. You need to check before ordering.

As To the area needed for the B post weld, we cut a three sided piece and pulled it forward leaving the fourth side attached. Size was about 4" high and three inches wide. Using a MIG welder we could insert the tip in easily to access the weld. If you decide on this I can try to give you an indication of the location for the cuts.

As To the area needed for the B post weld, we cut a three sided piece and pulled it forward leaving the fourth side attached. Size was about 4" high and three inches wide. Using a MIG welder we could insert the tip in easily to access the weld. If you decide on this I can try to give you an indication of the location for the cuts.

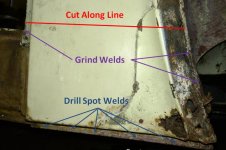

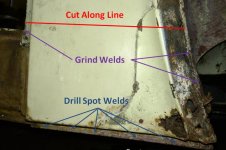

Charley, I would definitely like to see where you made the cuts. I just looked at the quarter panel, and it seems like it would be straight forward to grind and drill a few welds and then make a straight cut just above the sill. The lower 1/4 panel would then be completely removed for sill installation, and then welded back into place once complete. What do you think?

Regarding the purchased 1/4 panel, do you remember if it was pressed or hand made? I seem to remember reading somewhere that the pressed panels are a good fit, but I could be mistaken.

Regarding the purchased 1/4 panel, do you remember if it was pressed or hand made? I seem to remember reading somewhere that the pressed panels are a good fit, but I could be mistaken.

charleyf

Luke Skywalker

Offline

I believe the panel was hand made. But TRF (Albert) could tell you if the present panels are the same as they had three years ago.

From your picture I would say your situation would not require a new panel piece. But it is your call. I had a lot of rework on my piece on the bends found on the bottom of that new piece. Your proposal to remove the bottom of the 1/4 panel appears a reasonable approach. In fact I am going to reverse myself and say your approach is better than my small hole. The reason being that you need better access to be able to cut the B post from the sill. In my case I did a very tedious convoluted method of removing the rear of the sill. Kind of like building a ship in a bottle .

If you will look at the interior of the body and behind the door and B post. Looking down You can see the rear weld for that B post through the holes in the body . I am sure everything is rusty, but you can follow the sill and see where the B post joins the sill. That is the weld area.

when you cut the lower portion of the panel recognize that at the rear there is a second layer of metal being the inner fender.

From your picture I would say your situation would not require a new panel piece. But it is your call. I had a lot of rework on my piece on the bends found on the bottom of that new piece. Your proposal to remove the bottom of the 1/4 panel appears a reasonable approach. In fact I am going to reverse myself and say your approach is better than my small hole. The reason being that you need better access to be able to cut the B post from the sill. In my case I did a very tedious convoluted method of removing the rear of the sill. Kind of like building a ship in a bottle .

If you will look at the interior of the body and behind the door and B post. Looking down You can see the rear weld for that B post through the holes in the body . I am sure everything is rusty, but you can follow the sill and see where the B post joins the sill. That is the weld area.

when you cut the lower portion of the panel recognize that at the rear there is a second layer of metal being the inner fender.

This a photo of my starting point. The PO had done this at some point.

The door gap was over 1/2" too big so I had to do some re positioning of both the "A" and "B" posts.

I then made a piece to go where the missing piece should have been using the other side as a pattern and the wing as a guide. This patch was made before I got my HF shrinker and stretcher.

I probable should have cut out a bit more to give better access to the "B" post

David

The door gap was over 1/2" too big so I had to do some re positioning of both the "A" and "B" posts.

I then made a piece to go where the missing piece should have been using the other side as a pattern and the wing as a guide. This patch was made before I got my HF shrinker and stretcher.

I probable should have cut out a bit more to give better access to the "B" post

David

So I mounted the body using the recommended number of pads/spacers, and it seems that the body does not rest properly on the outer front frame. The side braces with aluminum spacers/pads hold the body up too high in the front.

What is the preferred method to correct this? Should I add additional mounting strips to the lower side brace and frame, or remove the aluminum spacers from the side brace body mount? The original configuration did have aluminum spacers, and I seem to remember the body was not properly resting on the frame.

What is the preferred method to correct this? Should I add additional mounting strips to the lower side brace and frame, or remove the aluminum spacers from the side brace body mount? The original configuration did have aluminum spacers, and I seem to remember the body was not properly resting on the frame.

charleyf

Luke Skywalker

Offline

The TR3 that I am working also does not sit correct in the front with the recommended spacers. I found that reversing the spacers on the shock tower greatly improved the fit.

For myself I preferred to get the middle or floor spacers set and then use what looked right on the shock towers, front end and rear.

For myself I preferred to get the middle or floor spacers set and then use what looked right on the shock towers, front end and rear.

I would go with what the manual says for now and put the all the shims in--- even the aluminum spacers. I believe 4 on each outrigger and 1 or 2 thick or thin in the front and back. The strip along the frame can wait a while.

The good news is this car has original paint and probably the original shims and does not look like the car had major body damage. The tub probably tweaked when it was unbolted or maybe tweaked a little when you moved it, but no big deal. You are going to be tweaking the tub the whole time you are replacing floors and inner sills; it will come back together probably not like it was, but like it will be when you are done which will be fine.

Yes keep an eye on shims and pads as you weld it back up, so you do not get too far off and do one side at a time. Some say you add shims here and there and that makes all the body panels line up perfect; that has not been my experience.

As you move through this, the doors and the front fenders where the door meet the fenders is the most tricky part, so keep an eye on that and you will be fine. It is a car and not a piano, but they do make music plus the restoration becomes an artistic expression of you--- and it is easy to get in the perfectionist trap and do nothing. I would maintain that this is a learning process and anything you do--- can be undone. The trick is to keep moving because when you are done, you will be able to look back and say I should have done this different, and that will be cool.

steve

The good news is this car has original paint and probably the original shims and does not look like the car had major body damage. The tub probably tweaked when it was unbolted or maybe tweaked a little when you moved it, but no big deal. You are going to be tweaking the tub the whole time you are replacing floors and inner sills; it will come back together probably not like it was, but like it will be when you are done which will be fine.

Yes keep an eye on shims and pads as you weld it back up, so you do not get too far off and do one side at a time. Some say you add shims here and there and that makes all the body panels line up perfect; that has not been my experience.

As you move through this, the doors and the front fenders where the door meet the fenders is the most tricky part, so keep an eye on that and you will be fine. It is a car and not a piano, but they do make music plus the restoration becomes an artistic expression of you--- and it is easy to get in the perfectionist trap and do nothing. I would maintain that this is a learning process and anything you do--- can be undone. The trick is to keep moving because when you are done, you will be able to look back and say I should have done this different, and that will be cool.

steve

CJD

Yoda

Offline

Like Steve says...start with the manual recommended shims. It will give you a starting reference point to work from. If you start off, then all you do will be off. . Later you may need to “tweak” the door gaps by altering shims, making it important that you have shims there to tweak.

I'm sorry guys, but my last post was in error. The pictures I attached are with the number and location of sill spacers that were removed 15 years ago. That is, 2 square spacers on the front sills, and 3 square spacers on the rear sills. If I install the recommended number of square sill spacers (4 all around), the whole body is lifted and the recommended number of pads/aluminum spacers in the engine compartment seem to be about right. The only problem is that the engine compartment body mounting holes on both sides are now partially blocked! I ground them out just slightly, but you can see where the mounting bolts wore into the hole edges over the years. And there is really no slack to move the tub front-back or left-right. So the only way to install the recommended number of pads/spacers is to enlarge these 4 body mount holes.

Having said that, I guess I'm still a bit fuzzy as to how to prepare the body for sill replacement. My thinking was that I needed to get the body mounting pads correct (meaning good for door gap and panel alignment) and then brace the tub front-back and left-right for sill removal and replacement. If everything held in place then no further action would be necessary once complete. But after reading your comments, I'm thinking I should secure the tub with recommended pads/spacers, brace the body, and then replace the sills. As long as everything doesn't move too much, door and panel gaps can be set by adjusting the shims later. Is this the best method?

Having said that, I guess I'm still a bit fuzzy as to how to prepare the body for sill replacement. My thinking was that I needed to get the body mounting pads correct (meaning good for door gap and panel alignment) and then brace the tub front-back and left-right for sill removal and replacement. If everything held in place then no further action would be necessary once complete. But after reading your comments, I'm thinking I should secure the tub with recommended pads/spacers, brace the body, and then replace the sills. As long as everything doesn't move too much, door and panel gaps can be set by adjusting the shims later. Is this the best method?

CJD

Yoda

Offline

You will be setting the door gaps when you weld in the A and B posts to the new inner sill. As you line up the A and B posts you very likely will be able to correct the front 45’s alignment issue too. If the doors are good now, then you can brace the door openings now. If your door gaps are currently off, then I would not brace now, as you’ll be bracing to an “off” position. If all works out you will start with the recommended shims and never change them. If you get through painting and something is slightly off...then you only have shimming to try to correct the problem without having to repaint.

Yes getting the sill out is a big step and project. Try and think of the body as flexing and twisting other than sliding, but yes the tub will slid also. When you stand back now, you can see that the inner sill removal is going to come out like pulling a tooth. So Be less intrusive as you can, but grind and drill out everything that has to be moved out of the way. To get started you can go onto the kick panel under the dash and undo the spot welds like on the outer sill. If things get too floppy, you can run some screw into the 2 pieces to hold things in place for a while. I suggest tipping the tub up on the frame maybe 8 inches; you can put some wire through the holes of the tub to the body mounts on the frame on adjacent side to keep the tub from sliding off the frame. I say this because I could move the tub around that way plus keep an eye on the mounting points. You mention you want to use or keep the floors in or reuse them and that sounds like something I would do, but I am not sure if it is way to go, maybe.

There are many ways to do this; I did not have the room to pull the tub and cut out the inner sill with the tub off the frame, so maybe that would be better for you I do not know.

For now, I would not enlarge any holes because the new sills are going change everything a little. The car panels like the front fenders bolt to the sill and the little rear quarter panel laps over and welds to the sill under by the B post on the inside and outside, so the most the cars is inter-woven back on the sill, so getting the sill back into its new home helps align the placement of the sill, and requires a lot of fiddling, so things are going to be a little different, so I would suggest not enlarging any holes for now. Like John maintained the A and B post get welded later for the precise door opening. You got this; it is not too difficult.

Steve

There are many ways to do this; I did not have the room to pull the tub and cut out the inner sill with the tub off the frame, so maybe that would be better for you I do not know.

For now, I would not enlarge any holes because the new sills are going change everything a little. The car panels like the front fenders bolt to the sill and the little rear quarter panel laps over and welds to the sill under by the B post on the inside and outside, so the most the cars is inter-woven back on the sill, so getting the sill back into its new home helps align the placement of the sill, and requires a lot of fiddling, so things are going to be a little different, so I would suggest not enlarging any holes for now. Like John maintained the A and B post get welded later for the precise door opening. You got this; it is not too difficult.

Steve