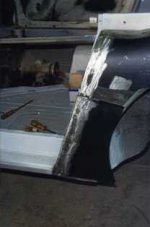

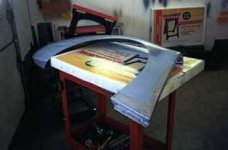

Hi Bob, As Roscoe said put in plenty of bracing. I braced my door openings with one horizontal brace at the top of the openings. Since I didn't have to remove my inner sills I figured that the inner sills would ensure that the lower part of the door opening would stay consistent. the inner sills are about the only thing that I didn't have to remove, I also had to replace the latch pillars as well as the rear outriggers and floor, part of the driveshaft tunnel and the rear bulkhead behind the seats, also the fenders, that is a story in itself I hope you don't have to go to the extent that I did with the fenders. As far as locating the outriggers, I didn't read one body spec from any publication. I created datum lines and measuring points myself and put the outrigger back in exactly the same spots the old ones were. My main data line for the outriggers was one of the braces that I welded in to brace the cockpit. I welded it in laterally right across just behind where the seat were and directly above the outriggers. It was welded to the tops of the inner fender panels a few inches above the rear seats but directly about the outriggers. I dropped measurements from this bar (it was 1/2 " angle iron) to the outrigger especially to the outer end of the outrigger. I took measurements also from rear seat vertical bulkhead at its lowest point near the floor and at the point where it joined the inner fender panel. That point would not be moving while I had the outriggers out. My springs fit in perfectly when the job was done. I did keep the engine and trans mounted in the car while I did the body. I believe this does help to keep the body from shifting some while doing the work and it maintains the stress on the frame that is normally present. I have a few pictures that I can attach to show some of the work that can be done, I hope you don't have to go to the extent that I did to get panel to match. I bought new fenders for the rear that didn't even come close to fitting the car. I don't know who made the fenders but they were way off and I bought them with the agreement of no return so I decided to make them fit. Unfortunately I can't find pics of the outrigger installation. But in a few pics I can show you wil see (just barely) the cross brace that I used to drop measurements for the outriggers. i have 5 pics I may have to put a couple in another post. Dave.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>