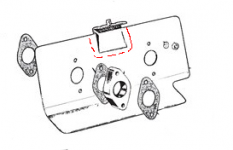

I'm eying my so-so heat shield (and the large crack in it) and contemplating making a new one out of stainless.

Any advice on how to set up that top bit that holds the throttle cable? I wondered about cutting the top part off the original and adding it to the new one.

Any advice on how to set up that top bit that holds the throttle cable? I wondered about cutting the top part off the original and adding it to the new one.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>