Just completing my first year as a BJ8 owner, and am struggling to separate the tranny to replace a failing clutch. I've read darn near every thread here, including TimK's excellent write up at https://www.britishcarforum.com/bcf/showthread.php?77420-Transmission-Removal-Replacement

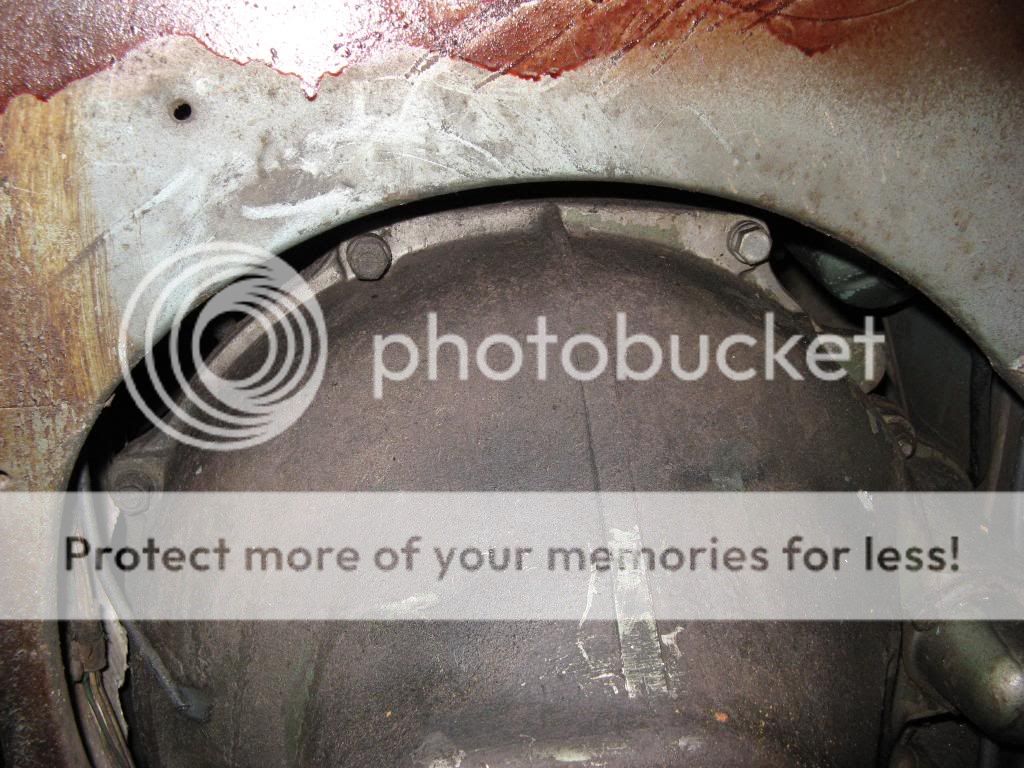

It took all of two and a half hours to get all the connections free, the tranny fully supported, and down to the last two bolts, but try as I might I just can't get access to the dowel bolt at 11:00 or the standard one at 9:00:

All other Bolts were fairly straightforward with sockets or short ratcheting or open end wrenches but these two are so close to the transmission I can't get a socket around them, nor can I use an open end wrench due to the throttle linkage (for the 11:00) or the sides of the tranny tunnel (9:00) limiting access. I tried a thinner 9/16 socket but there wasn't even room to squeeze that between the bolt head and the transmission body.

Best I can find no one here has posted about an issue accessing these two bolts so I must be missing something really simple, but two days later and I still don't know what I'm doing wrong! Any help would be greatly appreciated.

It took all of two and a half hours to get all the connections free, the tranny fully supported, and down to the last two bolts, but try as I might I just can't get access to the dowel bolt at 11:00 or the standard one at 9:00:

All other Bolts were fairly straightforward with sockets or short ratcheting or open end wrenches but these two are so close to the transmission I can't get a socket around them, nor can I use an open end wrench due to the throttle linkage (for the 11:00) or the sides of the tranny tunnel (9:00) limiting access. I tried a thinner 9/16 socket but there wasn't even room to squeeze that between the bolt head and the transmission body.

Best I can find no one here has posted about an issue accessing these two bolts so I must be missing something really simple, but two days later and I still don't know what I'm doing wrong! Any help would be greatly appreciated.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>