Jim 58 BN6

Jedi Trainee

Offline

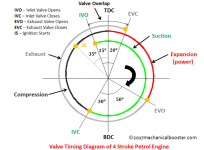

Wow 90degrees. Randy is, as usual, correct, and I apologize if I contributed to the confusion. When you said that both valves were closed at TDC, and the crank and pointer basically lined up, I figured there wasn't a cam timing problem - I mean, the valves were closed, right? Then I looked at a valve timing diagram, and lo and behold, with the cam 90degrees advanced*, both valves look to be "closed", and 180 cam degrees later, the intake is opening (or open), and exhaust is closed. Just like your pictures. The timing diagram is attached (generic, not Healey specific).

Anyway, I'm glad you found the problem. It might be worthwhile to have a friendly discussion with the engine builder. Good Luck, Jim

*Edit: I guess I meant retarded...

Anyway, I'm glad you found the problem. It might be worthwhile to have a friendly discussion with the engine builder. Good Luck, Jim

*Edit: I guess I meant retarded...

Attachments

Last edited:

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>