-

Hey Guest!

Hey Guest!

British Car Forum has been supporting enthusiasts for over 25 years by providing a great place to share our love for British cars. You can support our efforts by upgrading your membership for less than the dues of most car clubs. There are some perks with a member upgrade!**Upgrade Now**

(PS: Upgraded members don't see this banner, nor will you see the Google ads that appear on the site.)

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Victories.....for Mac

- Thread starter Tr3aguy

- Start date

Tr3aguy

Jedi Knight

Offline

So I am boxing up the carbs to send off for a rebuild! I have spares, so I am sending these to have for testing and I can hook them up to get the blue car running. I have a line on a lift and I just have to find a way to get it here! It would be great, it is a nice 4 post, pics hopefully to follow!

M_Pied_Lourd

Darth Vader

Offline

Cool. When is your garage get together? You could have a lift installation party

Cheers

Tush

Cheers

Tush

M_Pied_Lourd

Darth Vader

Offline

Then, Friday is the day I'll be envious

Cheers

Tush

Cheers

Tush

Tr3aguy

Jedi Knight

Offline

Why underwater rating! The motor does sit up pretty high on the post!

Uuuuuew...Aaaaaahhh! I want one!

Is it even underwater rated?

Tr3aguy

Jedi Knight

Offline

Ahhh sometimes you just need to pay attention to the obvious. Someone was a little sticker Happy.

It sports a scuba flag!?!

Tr3aguy

Jedi Knight

Offline

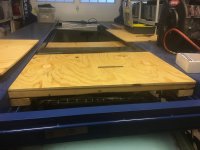

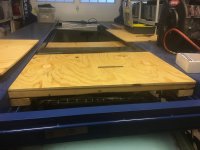

So today's project was to create more ample storage on the top part of the lift. I wanted something removable in sections and fairly strong but could not pay the manufacture pricing. After throwing some ideas around I settled on 2 x 4s and plywood. So it turned out that with all of regular dimension of the lumber I would just need to screw together after cutting to size. I opted for two foot wide sections, that way it could be removed fairly easily. As the project progressed I realized another bow of screws would be on the list so off to Home Depot.

This is really to store the body of the Tr3 and give it a stable base because of the narrow width of the Tr3 sans the frame. So here is a picture of one finished panel in place

So after tomorrow I should be able to get the rest of the panels complete and move the body over so I can resume tear down on the frame. Once that frame gets to the point of restored and rolling I see the two parts changing places so I can address more sheet metal repairs. I would put it in the house but my wife it not as accommodating as some forum members I know (John).

oh FYI the black part behind the plywood is the steel lift support that comes with the unit. I plan on keeping that in the center of the body just as extra safety.

This is really to store the body of the Tr3 and give it a stable base because of the narrow width of the Tr3 sans the frame. So here is a picture of one finished panel in place

So after tomorrow I should be able to get the rest of the panels complete and move the body over so I can resume tear down on the frame. Once that frame gets to the point of restored and rolling I see the two parts changing places so I can address more sheet metal repairs. I would put it in the house but my wife it not as accommodating as some forum members I know (John).

oh FYI the black part behind the plywood is the steel lift support that comes with the unit. I plan on keeping that in the center of the body just as extra safety.

CJD

Yoda

Offline

I hate to admit...but many of the best things in life are made from 2x4's and plywood!

Oooops.

Had to wipe the drool from my face from looking at the pic of the that nice, clean, beautiful lift again!!

Edit...and don't worry. These Triumph projects last so long that she will eventually break!

Oooops.

Had to wipe the drool from my face from looking at the pic of the that nice, clean, beautiful lift again!!

Edit...and don't worry. These Triumph projects last so long that she will eventually break!

Tr3aguy

Jedi Knight

Offline

So today my helper gave me some final resolution to extra support on the center section of the lift. So here he is with expert cordless drill handling skills. Of course we had to make sure it would bear weight!

The next step was to unclutter the current Tr3 frame and todecide what was going to the top of the lift. I called in a few favors with friends and neighbors to lift the body off of the frame, then position it on the lift. The hardest part was clearing the shock housing on the frame to get the body off, using 3 people. I decided to grab the rear end of the car coming out off the garage because I knew what to step over. It was also the heaviest part of the car.

So now we have a working area in the garage again. I picked up a couple new additions for the garage to make life a little easier. I have a retractable hose reel for air and electrical lines. I need to mount them and I am still searching for the optimum locations.

Here is the last picture to show that I will have plenty of room to operate once the cars are drive able. The windscreen is not on the blue car which is why I am able to set the lift so low. I still have a good 3 to 3 1/2 feet left to go before I top out on max lift height.

The lonely frame sits in the other bay awaiting tear down. I am saving that for the GYHD(Get Your Hands Dirty) session our car group has. I will have them over on March 25th. Any tips on how to properly check the frame for damage would be greatly appreciated. I am trying not to miss any crucial details before building it back up.

Now back to some car work.

JP

The next step was to unclutter the current Tr3 frame and todecide what was going to the top of the lift. I called in a few favors with friends and neighbors to lift the body off of the frame, then position it on the lift. The hardest part was clearing the shock housing on the frame to get the body off, using 3 people. I decided to grab the rear end of the car coming out off the garage because I knew what to step over. It was also the heaviest part of the car.

So now we have a working area in the garage again. I picked up a couple new additions for the garage to make life a little easier. I have a retractable hose reel for air and electrical lines. I need to mount them and I am still searching for the optimum locations.

Here is the last picture to show that I will have plenty of room to operate once the cars are drive able. The windscreen is not on the blue car which is why I am able to set the lift so low. I still have a good 3 to 3 1/2 feet left to go before I top out on max lift height.

The lonely frame sits in the other bay awaiting tear down. I am saving that for the GYHD(Get Your Hands Dirty) session our car group has. I will have them over on March 25th. Any tips on how to properly check the frame for damage would be greatly appreciated. I am trying not to miss any crucial details before building it back up.

Now back to some car work.

JP

M_Pied_Lourd

Darth Vader

Offline

I said it before but, man, am I envious!

Cheers

Tush

Cheers

Tush