Offline

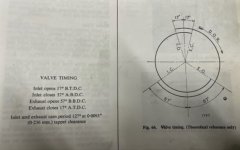

Taking back up on this fine old topic, and seeing some of what Mike (Popeye) and others have said, here's my issue. I followed both the Yakov Youtube video and a few good articles. I have TDC right on the mark. I also "degreed" the camshaft using Yakov's #1 cylinder intake valve lift methodology, and I set the maximum fully open point at which the crankshaft was set to 110 degrees after TDC (using the specs in the Triumph Shop Manual).

Yakov says I'm done and that I can fix the chain and move on, but I'm puzzled why I can't verify any of the other timing data shown in the Shop Manual. For example, shouldn't I be able to rotate the crank and see valve cam action corresponding to shop manual specs?

Also, I’m wondering about the two crank strokes, compression and exhaust. If I had the intake for Piston #1 at its highest point and set the crank to the correct corresponding degree (110 ATDC), and then verified that measurement with a dial gauge, with averaging, I assume everything must be right and that I could not have been on the wrong stroke.

I’m actually off by 2.5 degrees, and I understand if I flip the cam sprocket I might eliminate that—though it might be trial and error, as it might get 2 degrees worse.

Anyway, I guess I’m just looking for some guidance on the difference between the compression and exhaust strokes, and why it seems there are confusing statements made. I note that in the Youtube video, which really is great, I believe Yakov says he first started with the crank on the compression stroke and then rotated the crank to bring intake valve tappet #1 to its highest point, fully open. I assume when he did that he was then on the exhaust stroke. I say that because the other extremely detailed article on this makes a big point of being on the exhaust stroke for the adjustments. See Engine Rebuild (nonlintec.com)

Finally, is there a simple test that I have everything right—the head is off and I’m nowhere near complete with the engine. In the article, it is stated:

"I measured the crank positions for a specific intake and exhaust tappet height above the minimum (I used 25 mils). Because of slack in the chain, these points must be approached while turning the crank and camshaft clockwise, the normal direction of the engine. If the chain is adjusted right, these points will be equally spaced either side of TDC; the actual value is not important. I measured precisely 7 degrees for both, so I was confident that the chain was installed correctly and the timing was right."

I guess by “above the minimum” he means you rotate the crank until the tappets are at their lowest point, then proceed from there.

Oh, well, I guess that’s it for now. Happy Thanksgiving everyone!

Yakov says I'm done and that I can fix the chain and move on, but I'm puzzled why I can't verify any of the other timing data shown in the Shop Manual. For example, shouldn't I be able to rotate the crank and see valve cam action corresponding to shop manual specs?

Also, I’m wondering about the two crank strokes, compression and exhaust. If I had the intake for Piston #1 at its highest point and set the crank to the correct corresponding degree (110 ATDC), and then verified that measurement with a dial gauge, with averaging, I assume everything must be right and that I could not have been on the wrong stroke.

I’m actually off by 2.5 degrees, and I understand if I flip the cam sprocket I might eliminate that—though it might be trial and error, as it might get 2 degrees worse.

Anyway, I guess I’m just looking for some guidance on the difference between the compression and exhaust strokes, and why it seems there are confusing statements made. I note that in the Youtube video, which really is great, I believe Yakov says he first started with the crank on the compression stroke and then rotated the crank to bring intake valve tappet #1 to its highest point, fully open. I assume when he did that he was then on the exhaust stroke. I say that because the other extremely detailed article on this makes a big point of being on the exhaust stroke for the adjustments. See Engine Rebuild (nonlintec.com)

Finally, is there a simple test that I have everything right—the head is off and I’m nowhere near complete with the engine. In the article, it is stated:

"I measured the crank positions for a specific intake and exhaust tappet height above the minimum (I used 25 mils). Because of slack in the chain, these points must be approached while turning the crank and camshaft clockwise, the normal direction of the engine. If the chain is adjusted right, these points will be equally spaced either side of TDC; the actual value is not important. I measured precisely 7 degrees for both, so I was confident that the chain was installed correctly and the timing was right."

I guess by “above the minimum” he means you rotate the crank until the tappets are at their lowest point, then proceed from there.

Oh, well, I guess that’s it for now. Happy Thanksgiving everyone!

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>