Merlin63Tr4

Jedi Trainee

Offline

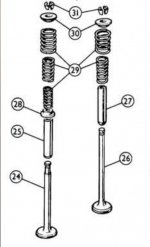

While helping a buddy trying to solve an overheating problem on his ’62 TR4 we discovered that the cylinder head had been reworked and converted to 5/16” exhaust valves, bronze valve guides and dual valve springs all around.

The issue we are not sure about is that the DPO’s machine shop used an exhaust valve guide collar (#28) on all the valves, intake and exhaust, and also seems to have used the valve spring set for the triple spring exhaust valve version (minus the small inner spring) and reused the valve spring collar (#30) used for triple exhaust valve springs cylinder heads.

The question is, should my buddy replace the current setup with all new valve spring collars for dual springs and a new dual spring valve spring set and remove the exhaust valve guide collar (#28) from all valves?

As far as I have been able to research qty (4) exhaust valve guide collar (#28) were only used on the exhaust valves using triple springs on TR3s and TR4s engines to CT21470E

Currently the cylinder head is all disassemble and soaking in Evapo-rust to dissolve a breathtaking amount of rust from the cooling passages. So replacing the springs, collars, etc would be trivial.

M.

The issue we are not sure about is that the DPO’s machine shop used an exhaust valve guide collar (#28) on all the valves, intake and exhaust, and also seems to have used the valve spring set for the triple spring exhaust valve version (minus the small inner spring) and reused the valve spring collar (#30) used for triple exhaust valve springs cylinder heads.

The question is, should my buddy replace the current setup with all new valve spring collars for dual springs and a new dual spring valve spring set and remove the exhaust valve guide collar (#28) from all valves?

As far as I have been able to research qty (4) exhaust valve guide collar (#28) were only used on the exhaust valves using triple springs on TR3s and TR4s engines to CT21470E

Currently the cylinder head is all disassemble and soaking in Evapo-rust to dissolve a breathtaking amount of rust from the cooling passages. So replacing the springs, collars, etc would be trivial.

M.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>