Just to be clear:

here is a quick description of the operation of the Synchro.

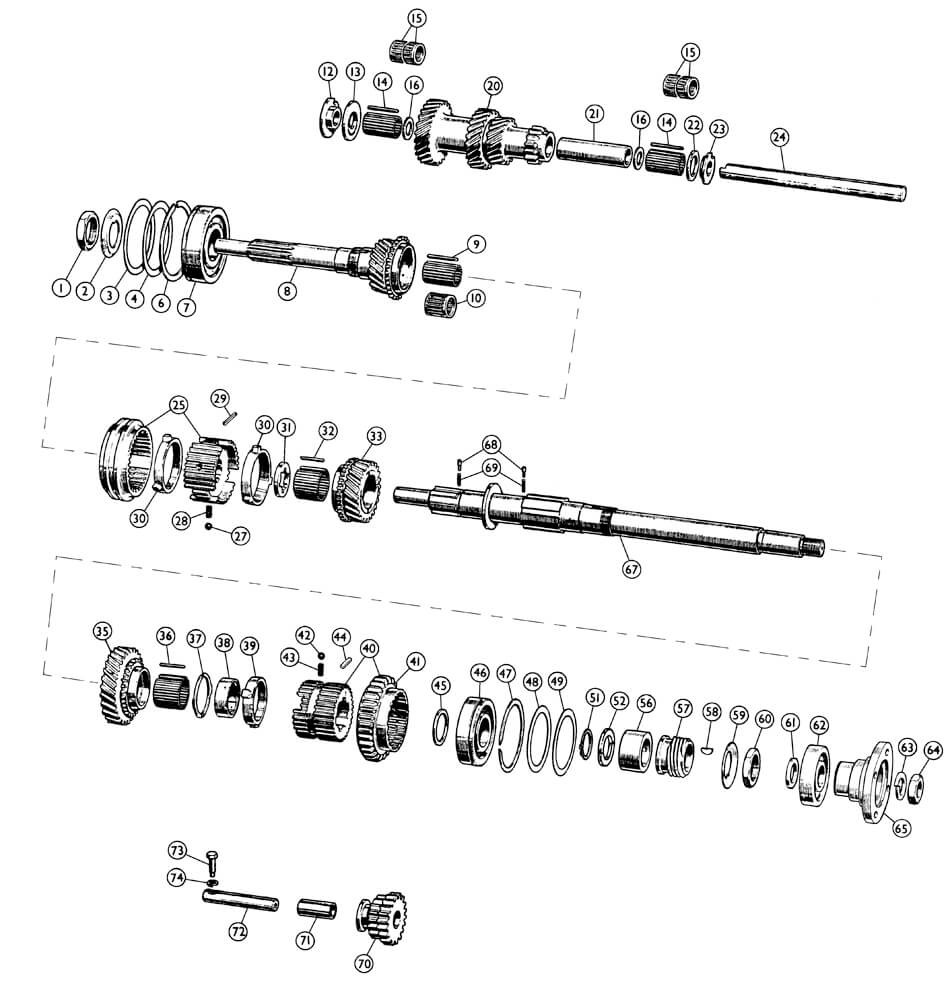

1.0 The gears are always in mesh, but spin freely in relation to the main shaft. They are selected by the dog clutch operation of the outer ring grooves sliding over the inner protrusions (“dogs”) On the gear itself. The inner hub is locked in step with the main shaft and the outer ring by the grooves. With no synchromesh, you would have to match revolutions (double de-clutch) to smoothly change gear, as you do in the non-synchromesh first gear.

2.0 So, synchromesh system A. A cone was added to the gear, and a matching inverted cone was added to the inner hub. As well, the inner hub had the spring loaded balls that engaged depressions in the outer hub, which was moved by the selector. As the outer hub was pushed towards the new gear, the outer hub engaged with the spring loaded balls, and pushed the inner hub + cone over the corresponding cone, before the dog clutch could engage. This bought the gear Protrusions and the outer ring up to the same speed, and allowed a crash less engagement of the dog clutch. BUT:

3.0 It was still possible to push the outer ring quickly enough to push the dogs together before the synchro had fully synchronised the gears (CRUNCH) (Hello, pre 4.2 E-Type Jaguar Moss boxes!). Hence the introduction of the Baulk (Synchro) Rings. Their purpose is to ensure that the full synchronisation has happened BEFORE the dog clutch engages, and hold out the outer ring until synchro has happened. The ring now sits between the inner hub and the gear, and has protrusions that prevent the outer ring sliding over the dogs, as it is twisted slightly out of synch with its matching slots on the outer ring, until the dogs and slots are in synch. (isn’t that a boy band?).

4.0 (and this is where I get into surmise, as I cannot find any literature on this) All well and good, but a slight issue, probably arising when the same gearbox was used in commercial situations. If the hub went one way for one gear, and the other for a second gear, it was possible that as you move the outer hub out of engagement, the springs and balls, although not in their true depressions, can take the inner hub towards the other gear, effectively trying to synchronise the other gear before the first has been disengaged. (another possibility I need to look into is if the outer hub is also redesigned to use the spring and balls to keep some pressure on the outer ring and in gear, the inner hub must be stopped from pushing the Baulk/synchro rings against the other gear, effectively wearing them out very quickly). Hence the ”beans”. Each bean is pressed into its matching slot by a ramp on the outer ring, stopping the inner hub from moving towards the other gear until released by the ramp once the gear has fully disengaged. As this effect would not be noticed in normal driving with out the beans, it is entirely possible for a bean to drop out to the bottom of the gearbox during assembly, and not be missed.

5.0 In order to get the beans working properly with the Dennis Welch hub, I first relieved the holes for the beans slightly, using a drill bit the same size as the Welch hole and working it back and forth a bit (air didn’t take much relieving, and then carefully ground down the ”hump” on the two ramps with a Dremel bit, followed by 1200 grit wet or dry, and finished with polish, to achieve a smooth surface. My tulip gearbox is now working beautifully!! As the three day Jaguar Mountain Rally over last weekend proved. A great test of one‘s relationship, if your partner is the navigator!

The one night stand that went wrong … 42 years later!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>