MichiganTed

Senior Member

Offline

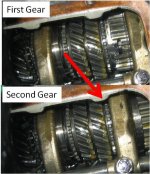

I just got the engine and brakes working sufficient to go around the block for the first time in my 65 Sprite project. Clutch feels good - goes into first no problem, no grinding. But I don't have second gear. It doesn't grind while trying to shift into second, there is just nothing there when shifting from 1-2 or from a 3-2 downshift. In the driveway, the shifter while trying 2nd gear doesn't go back into the "H" pattern as far as 4th gear goes. Possible linkage or broken shift rod?

Also, reverse is very hard to find. Wiggle wiggle push and jiggle and oh - there's reverse. But again, feels like linkage. Slides in clean once you find it and doesn't pop out of gear once your in it, it's just very hard to find.

I'm wondering if the two are related? Likely not. And if either / both are an in-vehicle repair or am pulling the trans? I haven't tried anything yet. and pulling the shifter cover plate won't likely reveal much. Thoughts?

Also, reverse is very hard to find. Wiggle wiggle push and jiggle and oh - there's reverse. But again, feels like linkage. Slides in clean once you find it and doesn't pop out of gear once your in it, it's just very hard to find.

I'm wondering if the two are related? Likely not. And if either / both are an in-vehicle repair or am pulling the trans? I haven't tried anything yet. and pulling the shifter cover plate won't likely reveal much. Thoughts?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>