-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trailing Arm Busing Removal

- Thread starter 71tr

- Start date

trrdster2000

Luke Skywalker

Offline

71tr, take them to a machine shop and let them press them out and take the new ones with you and take care of that at the same time. Or if you must DIY and have a good size vise, get a socket just a little smaller than the bush and one slightly larger than the hole, open up the vise put the small socket, flat face towards the bush on one end and the other socket open face towards the bush all in a vise and start turning, use a lot of WD40 or such and ware safety glass, sockets have been known to shatter. As a last ditch effort, bring it up to Salisbury. Wayne

LastDeadLast

Jedi Knight

Offline

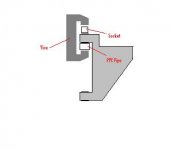

I used the "socket in the vice" method as well, but with a twist. I used a utility knife to cut the rubber lip around and edge of the training arm then cut a piece of PVC pipe to roughly resemble the profile of the side of the trailing arm OPPOSITE the side that I will be pressing the socket into. The theory being that I as press the rubber will be shoved into the center of the PVC pipe. I'm attaching a small pic that I made of my device. It was still a pain to do. It was hard to get everything lined up so it would push out. But I managed to do both training arms in one night using this method.

Attachments

LastDeadLast

Jedi Knight

Offline

You really really really need a vice

71tr

Jedi Warrior

Offline

Alright, this project is done. I kept it simple, just drilling relief holes into each bushing and then beating them out with a hammer, total project time/cost; 20 minutes and one broken drill bit. Just be sure to strike the steel sleeve with your hammer blows and not the rubber bush. Like trying to cut down a palm tree with an axe.