KVH

Obi Wan

Offline

I'm having an issue again.

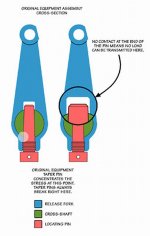

I'm looking at my new clutch shaft for my 4A and new, hardened taper pin.

Do I really need to drill a hole through the fork and shaft and install a horizontal pin (e.g., a bolt) as a precaution, or hasn't the strengthened pin supposedly resolved the issue?

If I drill through, I'll need one good carbide bit and better have a good eye to hit dead center through the fork and shaft, then I need the hole to fit tight with the bolt, etc. In other words, not terribly difficult but no cakewalk either.

Am I headed down overkill lane? I seem to go there frequently (and I'm too embarrassed to mention what I did recently, though maybe I'll get over it and share the story to spare others some grief, or to provoke mirth).

Thanks again.

I'm looking at my new clutch shaft for my 4A and new, hardened taper pin.

Do I really need to drill a hole through the fork and shaft and install a horizontal pin (e.g., a bolt) as a precaution, or hasn't the strengthened pin supposedly resolved the issue?

If I drill through, I'll need one good carbide bit and better have a good eye to hit dead center through the fork and shaft, then I need the hole to fit tight with the bolt, etc. In other words, not terribly difficult but no cakewalk either.

Am I headed down overkill lane? I seem to go there frequently (and I'm too embarrassed to mention what I did recently, though maybe I'll get over it and share the story to spare others some grief, or to provoke mirth).

Thanks again.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>