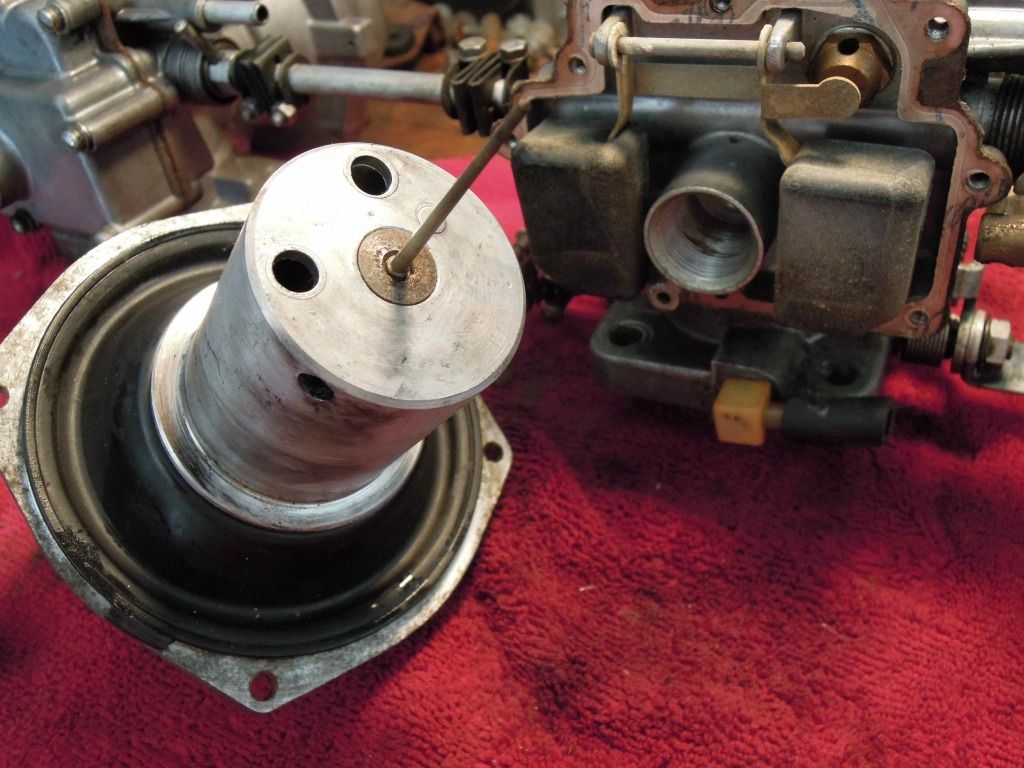

Finally got around to going through the carbs, before I put on any miles other than around the neighborhood,and it's probably a good thing. 13 years in the barn were not kind to them, even with less than 20k miles. I have a question about the "notch" in the bushing screw (1st picture.) I can't figure it makes any difference but thought I should ask.

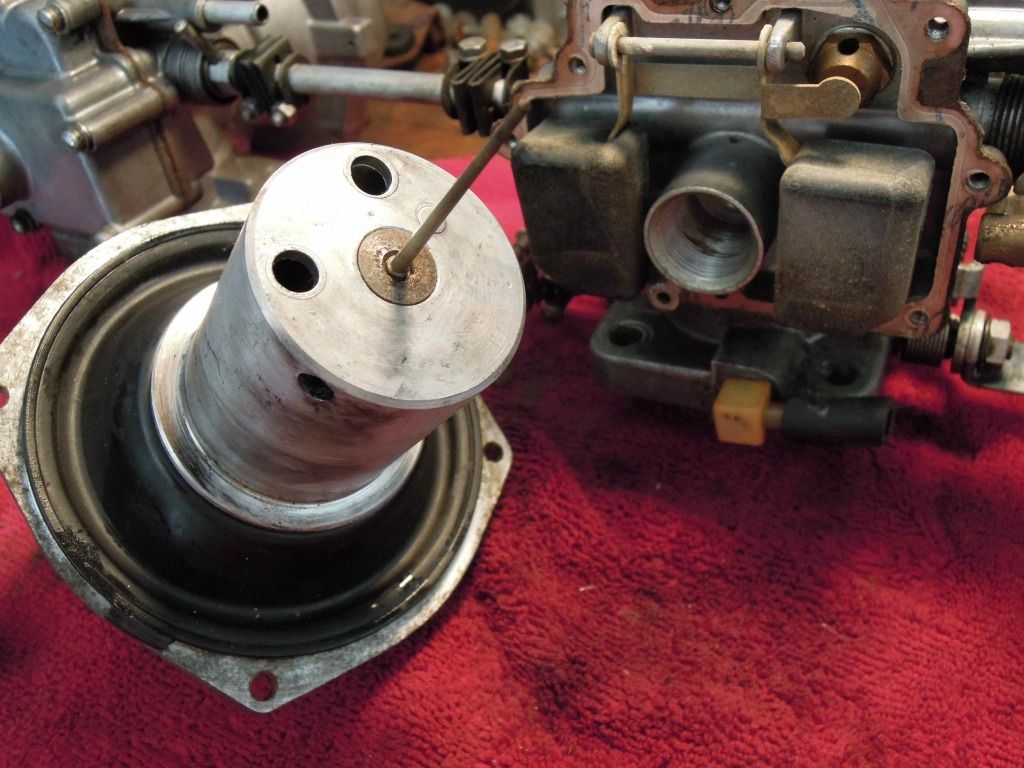

Before shot, everything is cleaning up well and all rubber seems ok.

Chunks that fell out during disassemble!

fine powder from the float chamber corner!

hopefully I'll get the other done today too.

Thanks

JD

Before shot, everything is cleaning up well and all rubber seems ok.

Chunks that fell out during disassemble!

fine powder from the float chamber corner!

hopefully I'll get the other done today too.

Thanks

JD

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>