deadair

Jedi Hopeful

Offline

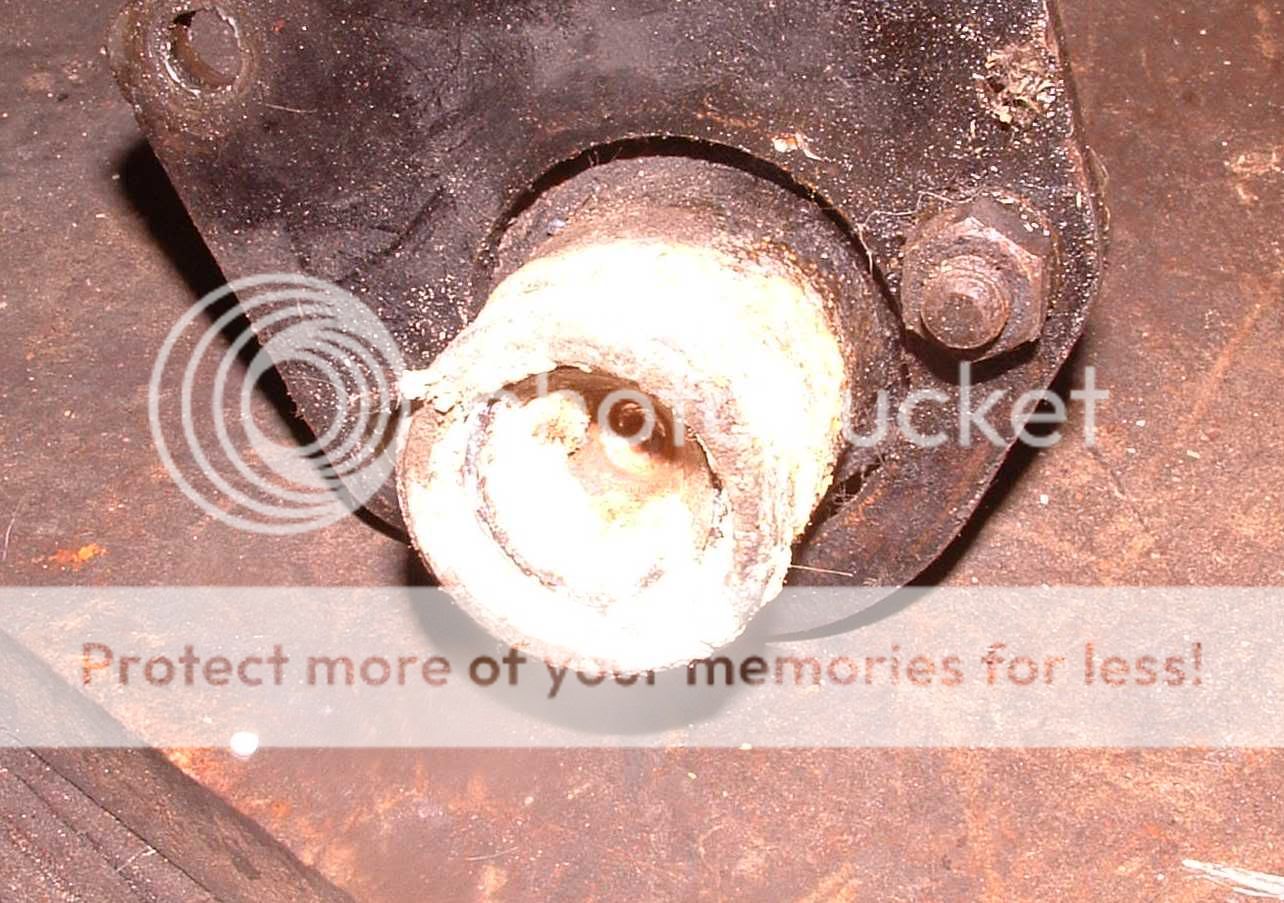

I'm having an impossible time removing one brake piston on each caliper. Here's what I've done so far:

1) Blown compressed air into the caliper. One piston comes out. It's the piston opposite the piston on the hose side on each caliper, which is the stuck one.

2) Pushed the removable piston back in and secured with a c clamp. Blow in compressed air. No joy on either caliper.

3) Removed the rubber seal on each stuck piston and sprayed WD-40 around each piston.

4) Repeat step 2. No joy.

5) Continue with steps 2 and 3 several times. No joy.

I've also tried prying the pistons out by inserting a pry bar in the piston groove and prying. No joy.

Any other ideas? I'm running out of my own.

1) Blown compressed air into the caliper. One piston comes out. It's the piston opposite the piston on the hose side on each caliper, which is the stuck one.

2) Pushed the removable piston back in and secured with a c clamp. Blow in compressed air. No joy on either caliper.

3) Removed the rubber seal on each stuck piston and sprayed WD-40 around each piston.

4) Repeat step 2. No joy.

5) Continue with steps 2 and 3 several times. No joy.

I've also tried prying the pistons out by inserting a pry bar in the piston groove and prying. No joy.

Any other ideas? I'm running out of my own.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.