-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A TR3A...Kicking accelerator pedal lowers idle?

- Thread starter karls59tr

- Start date

Offline

Could be anywhere in the linkage between pedal and carbs ... but most likely it's where the linkage passes through the firewall under the dash.

I'm lazy - it's less work to hit the pedal if it sticks, than to pull the thing apart to fix it. (The bushing at that firewall pass through is "problematic".)

Tom

I'm lazy - it's less work to hit the pedal if it sticks, than to pull the thing apart to fix it. (The bushing at that firewall pass through is "problematic".)

Tom

MGTF1250Dave

Jedi Knight

Offline

Aloha Karl,

A spray of silicone lube can help keep the throttle shaft moving freely in the nylon bushings. Other potential hang ups in the linkage are the various ball joints rod ends. Over the years you may find that where the stud was originally a sphere it has been worn to an oval and may cause the linkage to not operate smoothly. A bit of grease may help keep these joints moving easily. If the ball is badly worn the can easily pop apart.

A spray of silicone lube can help keep the throttle shaft moving freely in the nylon bushings. Other potential hang ups in the linkage are the various ball joints rod ends. Over the years you may find that where the stud was originally a sphere it has been worn to an oval and may cause the linkage to not operate smoothly. A bit of grease may help keep these joints moving easily. If the ball is badly worn the can easily pop apart.

TR3driver

Great Pumpkin - R.I.P

Offline

Oddly enough, I've been fighting a similar problem; except my idle is too high until I kick the pedal.

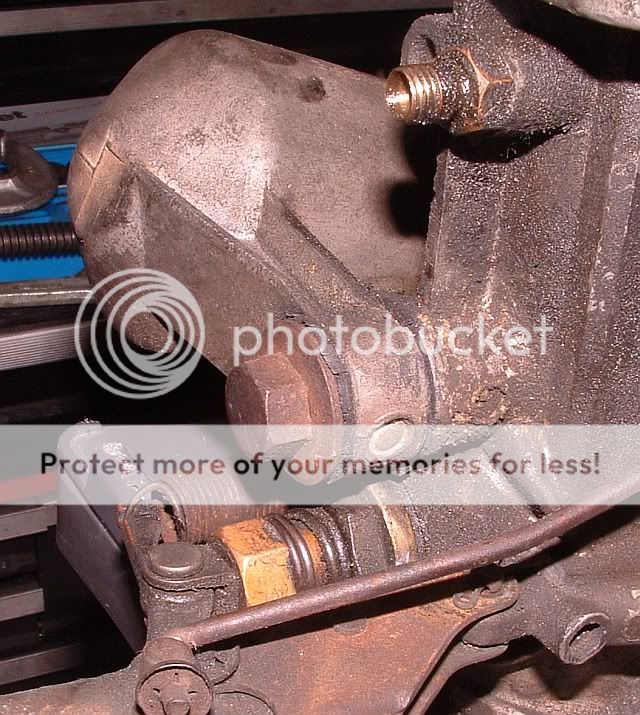

My linkage problem was that the bellcrank pivot was worn so badly that the bell crank was rubbing on the bolt that secures the pivot bracket to the intake manifold. I probably should have replaced the bellcrank, but I managed to sleeve it with some hard brass tubing.

Now it seems the problem is with the carbs themselves. I'm not sure if it is wear, or perhaps things got shifted in the accident (the carbs are the ones from the wrecked TR3A), but the idle stop lever is no longer holding the throttle plate centered in the bore. When the linkage pulls on the shaft, the shaft slides forward, and the throttle plate rubs against the inside of the bore.

I'm hoping that I can re-center the throttle plate this weekend (with the lever held up against the carb body); otherwise I'm going to move rebuilding the original carbs back to the top of the list.

Anyone know offhand who has the best price on a master rebuild kit?

PS, if your idle is "OK" when the throttle is stuck open, then just advance the idle stop screws until they hold it at the same place.

My linkage problem was that the bellcrank pivot was worn so badly that the bell crank was rubbing on the bolt that secures the pivot bracket to the intake manifold. I probably should have replaced the bellcrank, but I managed to sleeve it with some hard brass tubing.

Now it seems the problem is with the carbs themselves. I'm not sure if it is wear, or perhaps things got shifted in the accident (the carbs are the ones from the wrecked TR3A), but the idle stop lever is no longer holding the throttle plate centered in the bore. When the linkage pulls on the shaft, the shaft slides forward, and the throttle plate rubs against the inside of the bore.

I'm hoping that I can re-center the throttle plate this weekend (with the lever held up against the carb body); otherwise I'm going to move rebuilding the original carbs back to the top of the list.

Anyone know offhand who has the best price on a master rebuild kit?

PS, if your idle is "OK" when the throttle is stuck open, then just advance the idle stop screws until they hold it at the same place.

Marvin Gruber

Yoda

Offline

Same with mine. I however don't drive mine enough. If I drive it a few times, it seems to settle in and does fine. The 250 is the one driving me nuts. Going to change out the linkage on it next. I did have a problem with the mounting flange making the front throttle stick. Loosened all four nuts, retightened and no problem.

Marv

Marv

3 Likely Possibilities.

1) Check that the throttle linkage is not rubbing on intake manifold.

This is easy to miss; just look closely where the link goes by the intake manifold.

Easy fix,just loosen nut & move arm down a hair.

2) The brass throttle shafts wear the soft metal of the carbs badly. This happens a lot with SU carbs. The carbs can be reamed & bushed which eliminates this problem. Check for slop of the shafts.

3) Make sure choke cable is all the way OFF & that hi speed idle screw is not engaging when choke is off.

Bob

1) Check that the throttle linkage is not rubbing on intake manifold.

This is easy to miss; just look closely where the link goes by the intake manifold.

Easy fix,just loosen nut & move arm down a hair.

2) The brass throttle shafts wear the soft metal of the carbs badly. This happens a lot with SU carbs. The carbs can be reamed & bushed which eliminates this problem. Check for slop of the shafts.

3) Make sure choke cable is all the way OFF & that hi speed idle screw is not engaging when choke is off.

Bob

TR3driver

Great Pumpkin - R.I.P

Offline

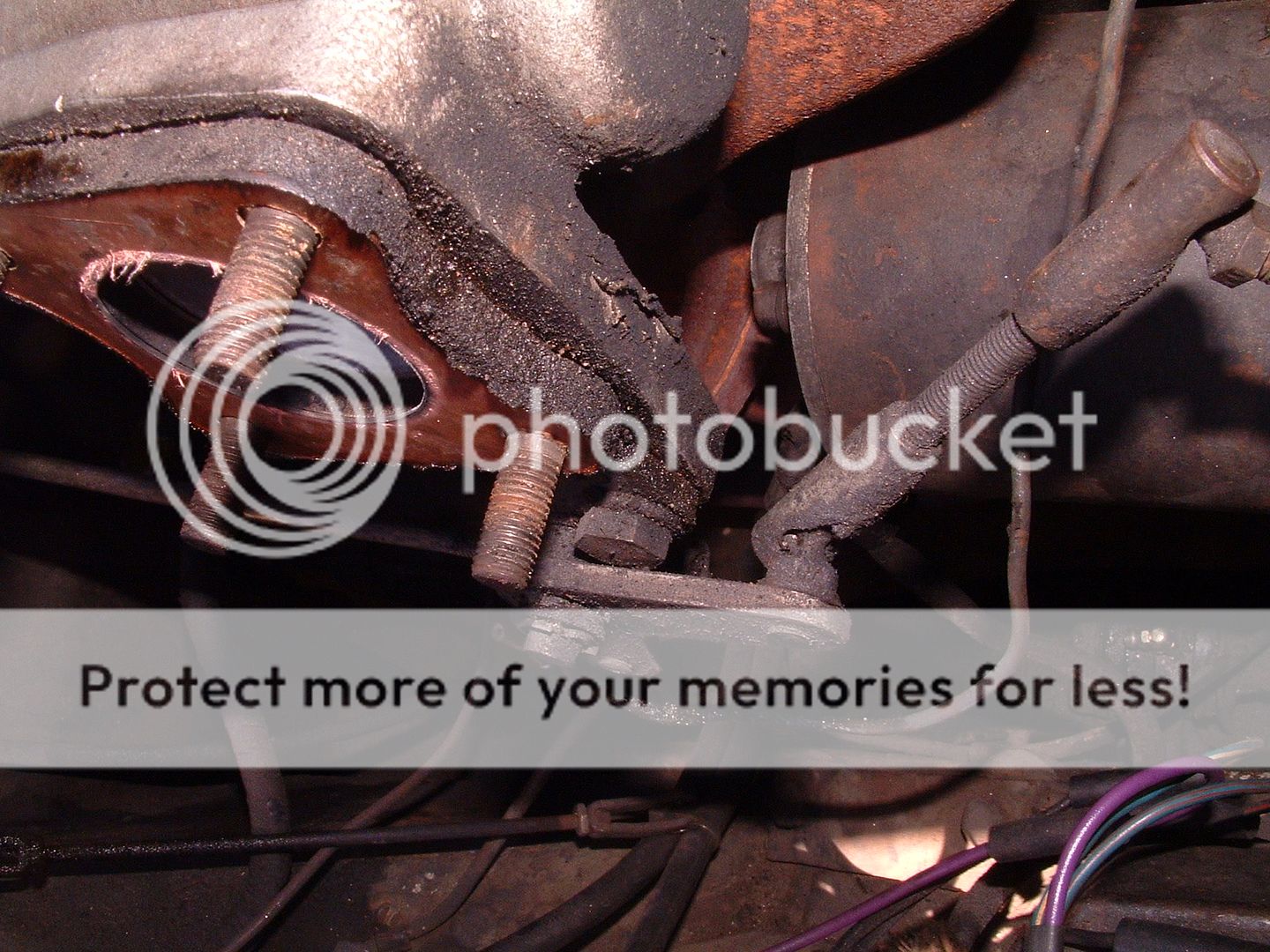

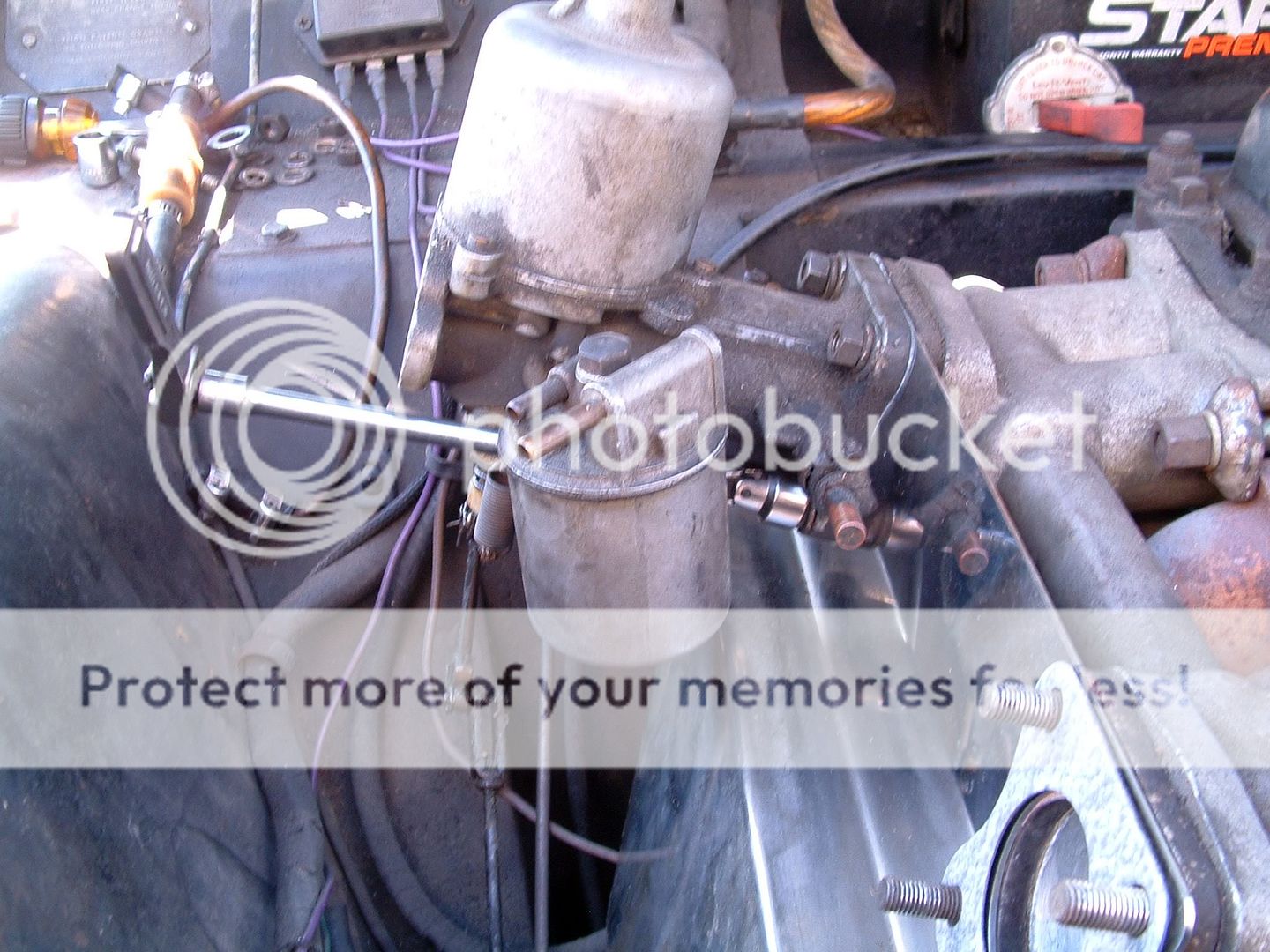

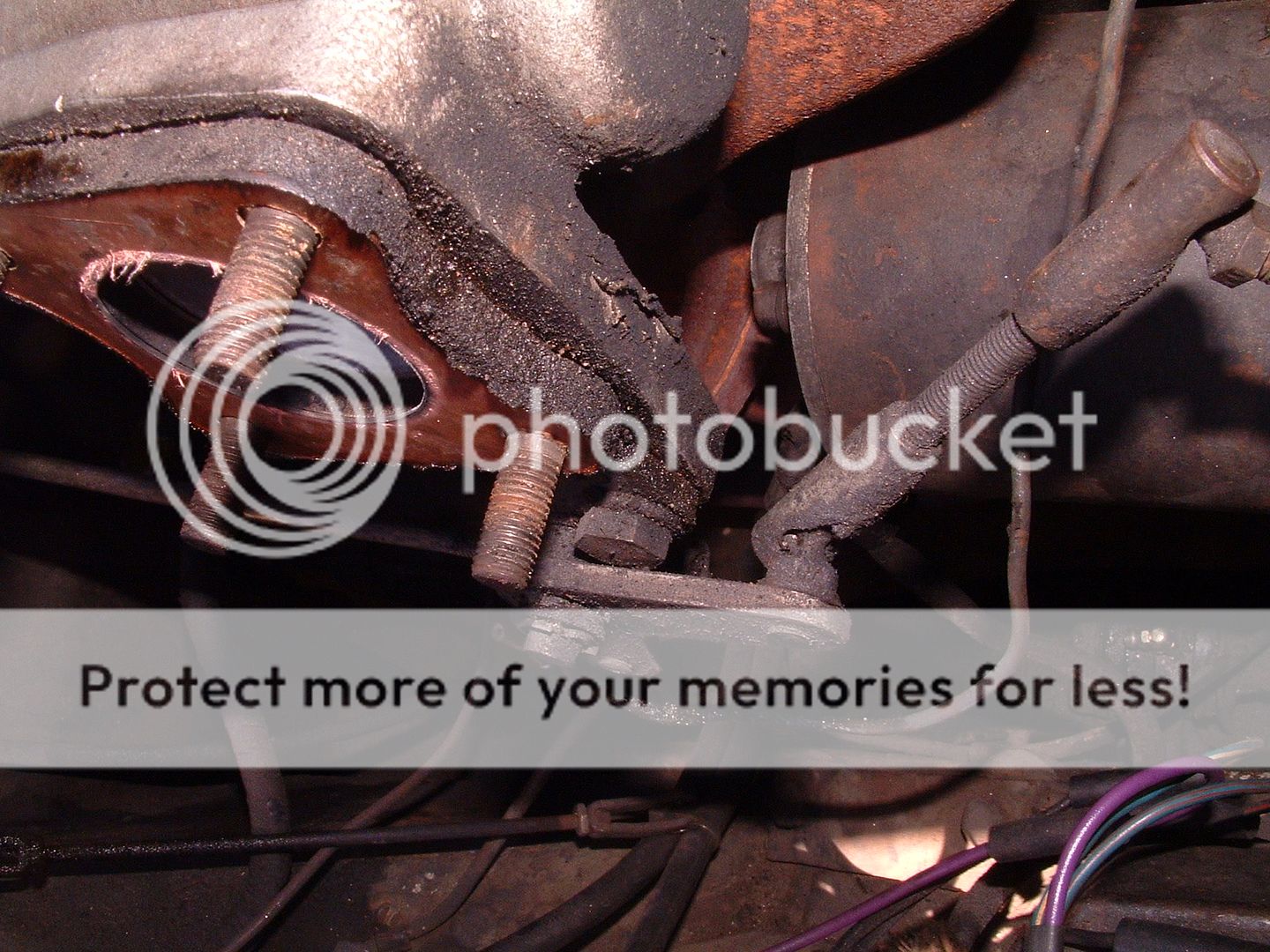

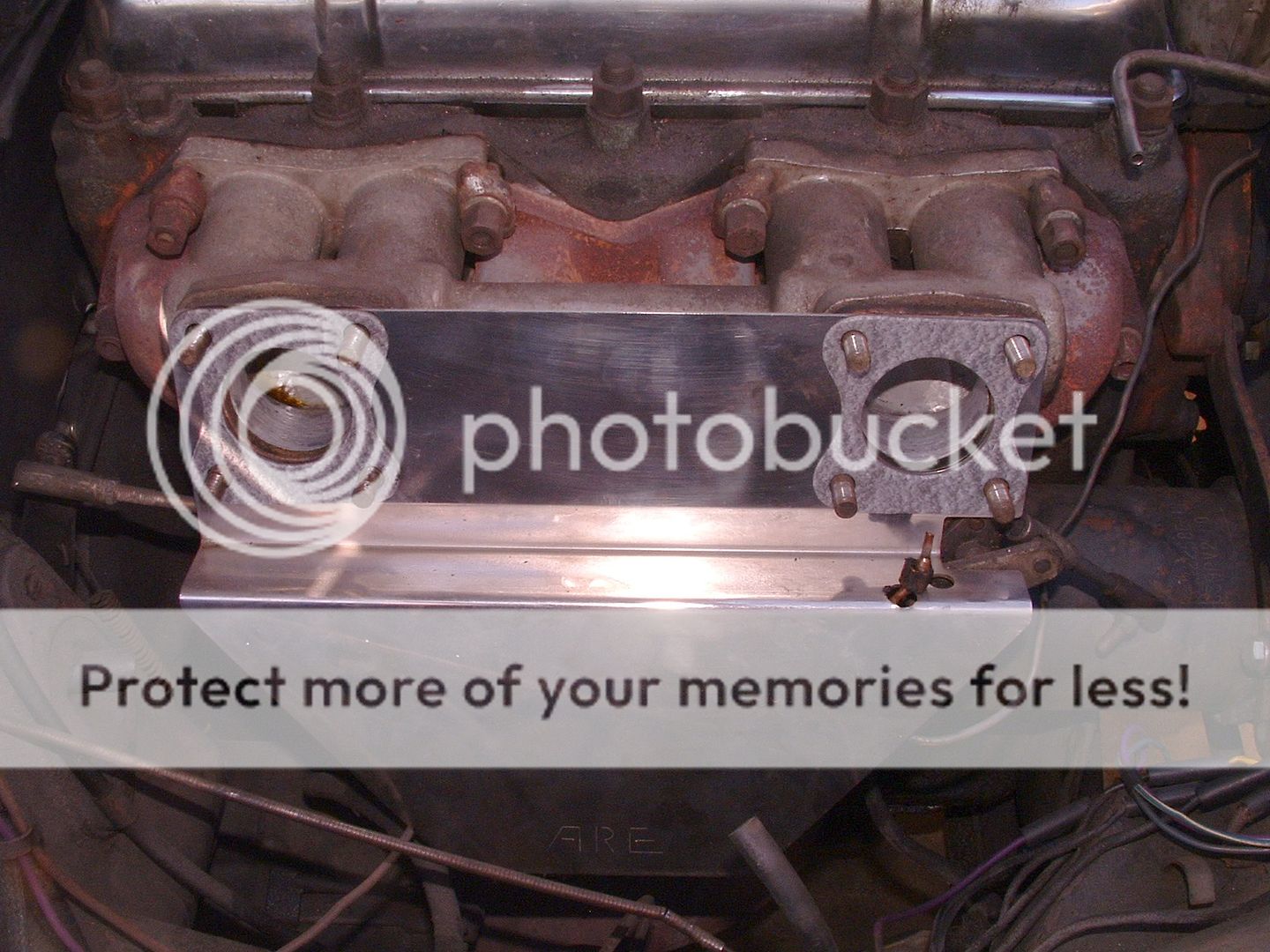

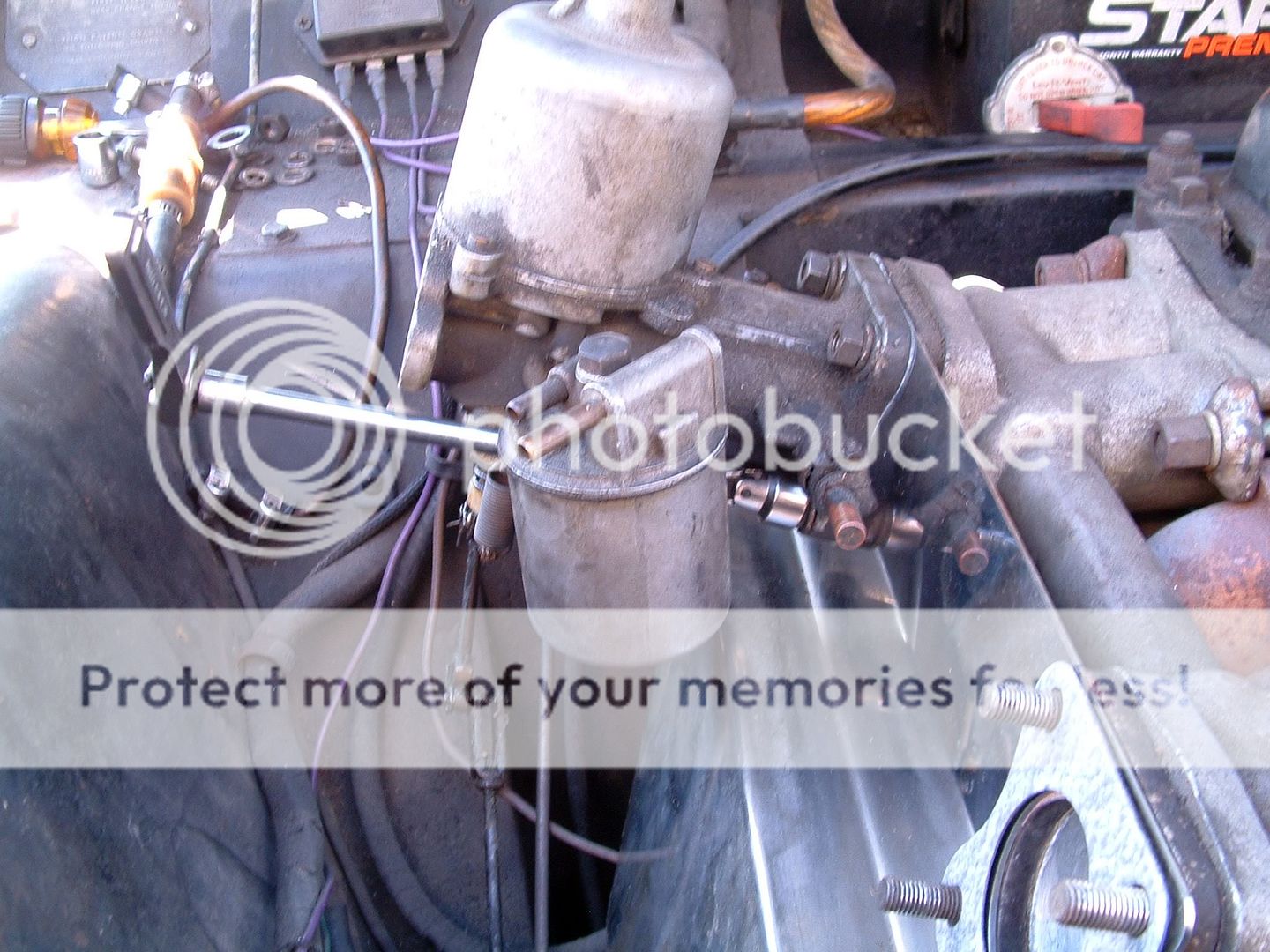

Here's a shot of where the linkage was rubbing on the bolt head. Very hard to see with things assembled, so I grabbed a shot while the carb was off.

Last weekend, I pulled the shaft out of the front carb, and added a spacer between the idle stop bracket and the carb body. That allowed me to center the throttle plate, with the stop bracket held firmly against the carb; then adjust the return spring on the other side to hold it there.

The result was most satisfactory, no more hangup at all, and I could back off on both return springs. That in turn reduced the flex in the throttle linkage (I have a split pin in one of the joints that really should have a solid pin) and made the throttle seem much more responsive.

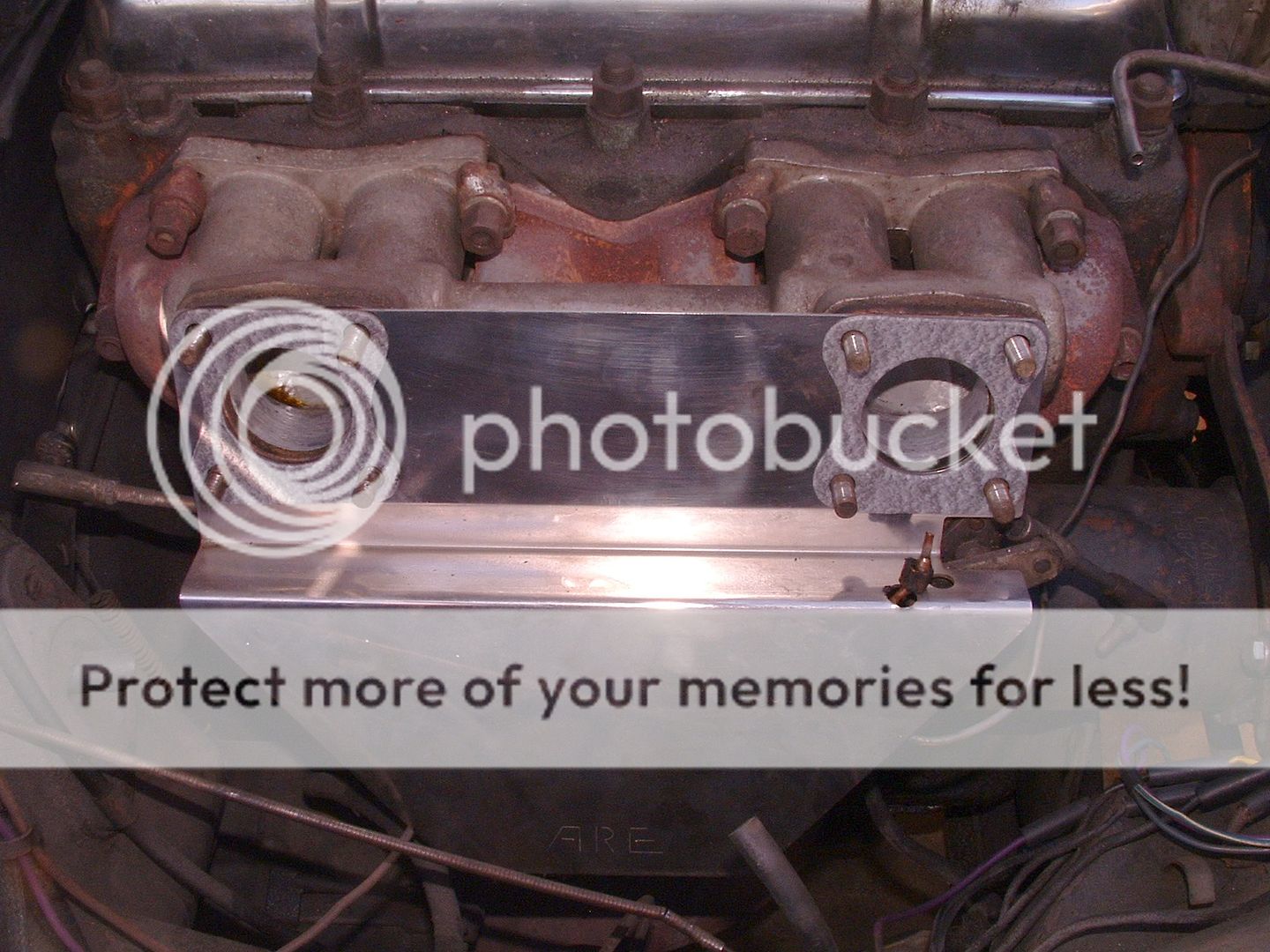

While I was in there, I also installed one of Joe Alexander's heat shields. Fit like it belonged there; the only tricky part was the vacuum line to the front carb. Next time, I'll attach the line to the carb through the shield first, before installing the rear carb.

Last weekend, I pulled the shaft out of the front carb, and added a spacer between the idle stop bracket and the carb body. That allowed me to center the throttle plate, with the stop bracket held firmly against the carb; then adjust the return spring on the other side to hold it there.

The result was most satisfactory, no more hangup at all, and I could back off on both return springs. That in turn reduced the flex in the throttle linkage (I have a split pin in one of the joints that really should have a solid pin) and made the throttle seem much more responsive.

While I was in there, I also installed one of Joe Alexander's heat shields. Fit like it belonged there; the only tricky part was the vacuum line to the front carb. Next time, I'll attach the line to the carb through the shield first, before installing the rear carb.

Offline

Randall - those are really interesting pictures.

My eyes aren't what they used to be ... what did you change to stop the linkage rubbing on the bolt head? Do you have an "after" picture?

Now I'm going to check mine, and see if I've got a similar issue. "Ay, there's the rub!"

Thanks.

Tom

My eyes aren't what they used to be ... what did you change to stop the linkage rubbing on the bolt head? Do you have an "after" picture?

Now I'm going to check mine, and see if I've got a similar issue. "Ay, there's the rub!"

Thanks.

Tom

Anthony_S

Senior Member

Offline

Hey Randall, I don't know if you purchased your master rebuild kit yet but I bought mine from Moss. I am hoping to install it this weekend. One thing to keep in mind is that they also sell a jet bearing kit which has things the master kit doesn't have you might want. So I bought both just to be sure and redo the whole thing.

What is the purpose of the heat shield? I kind of know but I'm curious what everyone else thinks about it. Is it a good idea to have?

What is the purpose of the heat shield? I kind of know but I'm curious what everyone else thinks about it. Is it a good idea to have?

Moseso

Jedi Knight

Offline

I had it. It did it's job and did keep the carbs cooler. It got in my way one-too-many times when I had to do something on the carb side of the motor. Need to hold your starter in your hands? First, out come the carbs. There was something else, but I can't remember what. I left it off after that and have not suffered any terrible problems in its absence.

TR3driver

Great Pumpkin - R.I.P

Offline

NutmegCT said:what did you change to stop the linkage rubbing on the bolt head? Do you have an "after" picture?

That IS the after picture! (about 2 years after) I unfortunately didn't take any "before" pictures, partly because I just didn't think of it, and partly because I didn't remove the carbs at the time. The main change was to insert a bushing into the bellcrank (cut from a piece of thinwall brass tubing from the local hobby shop). But I also ground away a bit of the bolt head, to increase the clearance. The bolt originally had some kind of raised logo on the head.

I'm also going to try to remember to put a drop of oil on that joint once in awhile (which is why it's so dirty), along with all the other moving joints in the throttle linkage.

Heim joints might last longer; but honestly, are you worried about having to replace those joints again in another 50 years? Heavy duty trucks use the same kind of joints and they last for literally millions of miles.

It doesn't happen often for me, but I have had situations where the carbs got hot enough for the fuel to boil. For example, last summer my Dad & I went on a run with the local club starting from the high desert and going up into the San Gabriel mountains. Even in the mountains, I'd estimate the air was 80+F and the sun was bright, a beautiful day. But, after we made a 5 minute "pit stop" at the top of a grade, the TR3 was very hard to start, blew black smoke, and didn't want to idle. (I wasn't the only one.) So, I'm hoping the carb shield will help with that.

I'm not too worried about starter access; I've never had a moments trouble since switching to a gear-drive unit back in 2001. But before that, the big Lucas wouldn't come out the top without removing the rear carb anyway. I found that, with some careful prying against the motor mounts, I could work it out the bottom. I also added a Helicoil to the top starter hole, to make it easier to install without removing the carb.

I also have a feeling that the rather toasted appearance of the float bowl gaskets

has something to do with excess heat radiating from the exhaust manifold.

TR3driver

Great Pumpkin - R.I.P

Offline

Anthony_S said:Hey Randall, I don't know if you purchased your master rebuild kit yet but I bought mine from Moss. I am hoping to install it this weekend. One thing to keep in mind is that they also sell a jet bearing kit which has things the master kit doesn't have you might want.

Thanks for the tip, Anthony. But when I went to look for another set of float bowl gaskets, I discovered that I already have all the parts on the shelf. And since the shim worked out so nicely, I'll move the carb rebuild to the back burner and concentrate more on the rear axle first.

TR3driver

Great Pumpkin - R.I.P

Offline

sp53 said:I am not sure, but it seems to me that if the idle is only raised a couple of hundred Rs that the vacuum of the running engine is holding the piston up just a little and when I hit the gas just a little that breaks the vacuum and lets the idles come down some.

The pistons are supposed to be lifted a small amount at idle, by the vacuum (aka depression) produced by the air flowing through the venturi (narrow space under the piston). It is possible for them to stick and affect idle rpm, by altering the mixture; but they have to be quite a bit out of place to change it by very much. In fact, that is the way you check that the mixture is correct, by lifting the pistons a bit and observing that the idle rpm doesn't change.

The most common way for a piston to bind at idle is for the jet to not be centered properly. This is a serious problem in itself, IMO, and should be addressed promptly. The needle rubbing on the jet will wear both of them over time, and change the mixture curve so it goes rich at idle. Then when you adjust the idle mixture to be correct, the mixture will be too lean at cruise, leading to loss of power, poor fuel mileage and overheating.

Unfortunately, I didn't realize that was the problem with Dad's TR3A until after it spit most of #3 cylinder out the tail pipe.

TR3driver

Great Pumpkin - R.I.P

Offline

NutmegCT said:Here's the thing that clue'd me in to the linkage binding as it passed through the firewall. If the warm engine started idling fast, I found I could gently lift the gas pedal with my foot about 1/4 to 1/2" inch. That would reduce the idle to normal.

But, that would also apply extra force to the linkage all the way to the throttle plates. I could also pop the throttles closed that way when the bellcrank was dragging on the bolt head. (And I went through all the hassle of replacing those bushings, with absolutely no improvement at all.)

IMO it's better to disconnect the various sections, and see which one binds with the others disconnected. This last time around, I could disconnect the linkage right at the front carb, and still get them to bind with the engine hot.

Got_All_4

Luke Skywalker

Offline

Hay Randall I often thought of getting a heat shield too for my 3 but was concerned that the shield would hold more heat in the lower engine compartment. Being that the generator pulls it's cooling air from the back side, wouldn't it pull in super heated air and over hea he generator?