TexasKnucklehead

Jedi Knight

Offline

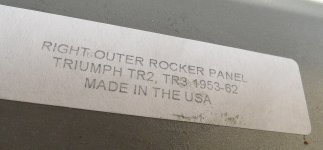

We all know the outer rocker panels are different on pre and post 60k cars, but I got a set marked "TR2 TR3 1953-1962". The one marked "right" is for the left and the one marked "left" is for the right. -I think. The rear of the rocker has a 90 degree bend over, about 1/4" and is perpendicular to the top and bottom edge. The front is at an angle where it meets the front fender. The front has a hole cut where Don has recently shown a small recess needs to be for door opening clearance. However, the replacements do not have additional material that goes under the front fender. Obviously some attention is required of the cut out hole, but is the additional fold under the front fender required?

I have a 1959, pre 60k...

My new rocker panels are flat, the ones on the car are curved to match the doors. Has anyone simply straightened the doors, instead of matching the curve along the length of the rocker? Or, could post 60k doors be used, instead of messing with the curve?

I have a 1959, pre 60k...

My new rocker panels are flat, the ones on the car are curved to match the doors. Has anyone simply straightened the doors, instead of matching the curve along the length of the rocker? Or, could post 60k doors be used, instead of messing with the curve?

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.