CraigLandrum

Jedi Hopeful

Offline

OK, carbs are tuned and throttle linkage back on, but for the life of me I can't seem to get the choke cable hooked back up in such a way as to be able to be operated by a human.

- Its a new choke cable from Moss

- New choke linkage rod and cable attachment pin

- I'm pulling the mixture rods back to take out the slack (like tghe book says to do), just to the point that any more would start changing the mixture, then I tighten the cable

- The cable seems to work smoothly when not hooked up, but once its is hooked up, seems to require way too much pull, and the rods barely move on the carbs - not even close to full travel. The required pull to get even as far I get is such that I'm scared I will break something if I use more.

The carbs are tuned up and engine runs smoothly, mixture is not too rich, not too lean.

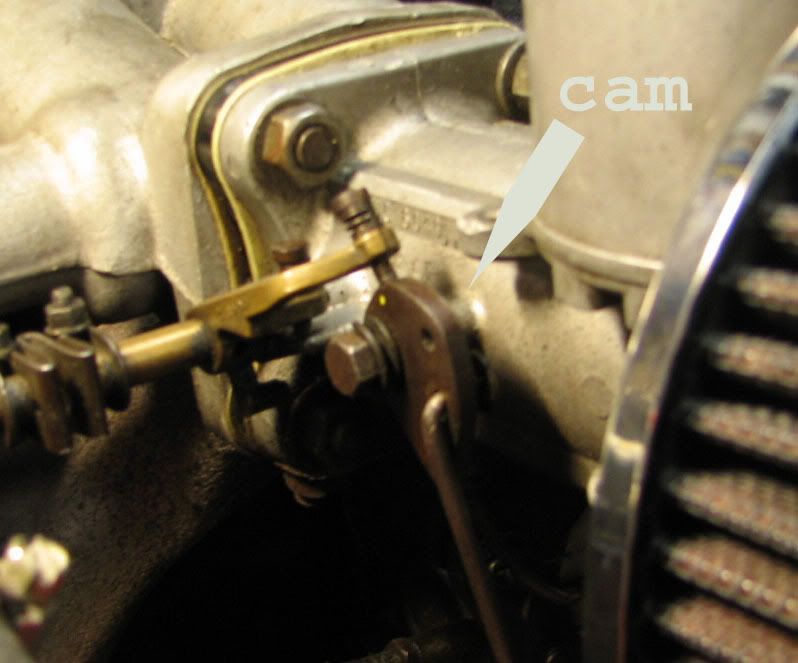

The cable casing gets clamped to an extension arm at the point the actual cable emerges from the casing at the end. The cable then extends out for about a couple inches or so and then gets threaded through the hole in the pin that goes through the mixture rod coupling.

When we installed the new choke cable we cut off surplus casing from the end of the cable to get rid of a bunch of slack that hung down inside the cockpit under the dash. Could we have cut off too much, thus making the cable bind under the tension that occurs when you pull on the knob?

FYI, the carbs were rebuilt - could something have gotten overtightened?

Any suggestion or insights would be welcome.

- Its a new choke cable from Moss

- New choke linkage rod and cable attachment pin

- I'm pulling the mixture rods back to take out the slack (like tghe book says to do), just to the point that any more would start changing the mixture, then I tighten the cable

- The cable seems to work smoothly when not hooked up, but once its is hooked up, seems to require way too much pull, and the rods barely move on the carbs - not even close to full travel. The required pull to get even as far I get is such that I'm scared I will break something if I use more.

The carbs are tuned up and engine runs smoothly, mixture is not too rich, not too lean.

The cable casing gets clamped to an extension arm at the point the actual cable emerges from the casing at the end. The cable then extends out for about a couple inches or so and then gets threaded through the hole in the pin that goes through the mixture rod coupling.

When we installed the new choke cable we cut off surplus casing from the end of the cable to get rid of a bunch of slack that hung down inside the cockpit under the dash. Could we have cut off too much, thus making the cable bind under the tension that occurs when you pull on the knob?

FYI, the carbs were rebuilt - could something have gotten overtightened?

Any suggestion or insights would be welcome.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>