-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR4/4A TR3/4 Gearbox Input Shaft

- Thread starter CJD

- Start date

TR3driver

Great Pumpkin - R.I.P

Offline

And that design carries into the six boxes till they changed the mesh angle on the teeth. There use to be a lot more of the NOS bushing type available. Purchased one a dozen years ago and had a shop drill, polish and press in the needle bearing. Do remember they complained mildly about the toughness of the steel to work with (it was about a '57 date on the box) and is still in a 4A daily driver.

No, that right. It was a cost saving measure, without sacrificing reliability (sort of). Though I do remember working on at least one failed bearing back then (when the gearboxes weren't all that old). Never did see a failed bushing. Just a lot fewer man hours in production. The early bushing and mating mainshaft required a good bit more machining. They just went up to an 'off the shelf' bearing size till they felt there was adequate safety margin for the load transfer.

CJD

Yoda

Offline

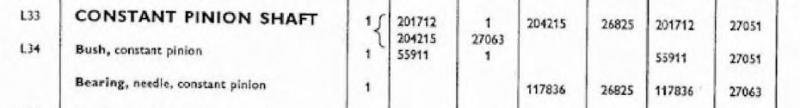

I finally got home and had a chance to take some measurements. The TR2 through TR3A input shaft has a mainshaft bearing ID of .91" The TR3B-TR6 early has the hole for the needle bearings that is 1.12".

Of note, the bearing surface of the mainshaft is the same size for both. So...it appears the input shaft for a TR2/3A will work with the TR4 box, so long as you use the bushing instead of the newer needle bearing. I would imagine the TR4 input shaft will work backwards to the TR3 also, so long as you use the needle bearings.

This may become important, as the later input shaft is becoming scarce! That seems interesting to me, as there were a lot more cars with the later shaft built. I guess those cars are getting rebuilt more frequently than the earlier cars?!?

Of note, the bearing surface of the mainshaft is the same size for both. So...it appears the input shaft for a TR2/3A will work with the TR4 box, so long as you use the bushing instead of the newer needle bearing. I would imagine the TR4 input shaft will work backwards to the TR3 also, so long as you use the needle bearings.

This may become important, as the later input shaft is becoming scarce! That seems interesting to me, as there were a lot more cars with the later shaft built. I guess those cars are getting rebuilt more frequently than the earlier cars?!?

TR3driver

Great Pumpkin - R.I.P

Offline

Since the SPC shows the mainshaft changing with the input shaft and bushing/bearing; there must be some difference. I'm guessing it had to be specially hardened to live with the needle bearings. So, if I were going to try to use a later input shaft with an early mainshaft, I might take Bob Schaller's advice and find (or machine) a bushing to fit instead of using the needle bearings.

Using a custom bushing might also be a means to saving an input shaft where that needle bearing has failed; but I haven't tried it. I've got the "ruined" input shaft though (which I use to align clutch plates).

Your last statement seems like a non sequitor to me. If there are a lot more cars, but they are being rebuilt at the same rate, it would still consume a lot more parts. But my guess is that the shortage indicates a higher failure rate, since the input shaft normally doesn't get replaced unless that bearing fails. Kind of supports Bob Schaller's. theory that the bushing gives longer service life.

https://drive.google.com/file/d/0B2...MmJmLWFiZGItNTI5ZjI3N2NjZTIy/view?usp=sharing

Using a custom bushing might also be a means to saving an input shaft where that needle bearing has failed; but I haven't tried it. I've got the "ruined" input shaft though (which I use to align clutch plates).

Your last statement seems like a non sequitor to me. If there are a lot more cars, but they are being rebuilt at the same rate, it would still consume a lot more parts. But my guess is that the shortage indicates a higher failure rate, since the input shaft normally doesn't get replaced unless that bearing fails. Kind of supports Bob Schaller's. theory that the bushing gives longer service life.

https://drive.google.com/file/d/0B2...MmJmLWFiZGItNTI5ZjI3N2NjZTIy/view?usp=sharing

mikephillips

Yoda

Offline

Seems to me that the bushing would be much more tolerant of low oil levels in the transmission. If the rollers aren't getting sufficient splash lubrication they start running with too little oil and quickly heat and start to fail where the bushing would be porous and retain oil. So that is probably why there seems to be a difference and tougher time finding a good later input shaft.