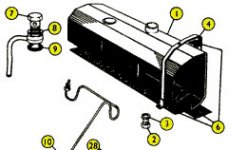

I'm installing a restored fuel tank in my TR-3A and am considering reconfiguring the fuel line connection at the tank outlet. The vendor catalogs and TR-3 Parts Catalog show two 180 degree loops in the line from the tank. Is there a technical reason, other than routing convenience, for having those loops in the line?

I have the Moss fuel line with the proper fitting and ferrule, but I'm concerned about the security of that union. It's the original tank, but the seat in the outlet is a bit rough. As a result, the ferrule isn't compressing as it should.

As a work around I found a 90 degree adapter that matches the threads on the tank and would let me mount the fuel line with a compression fitting parallel to the bottom of the tank. I've seen a photo on the forum in the past with this set up but I can't seem to find it again.

Thoughts anyone?

Rick...

I have the Moss fuel line with the proper fitting and ferrule, but I'm concerned about the security of that union. It's the original tank, but the seat in the outlet is a bit rough. As a result, the ferrule isn't compressing as it should.

As a work around I found a 90 degree adapter that matches the threads on the tank and would let me mount the fuel line with a compression fitting parallel to the bottom of the tank. I've seen a photo on the forum in the past with this set up but I can't seem to find it again.

Thoughts anyone?

Rick...

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>