Offline

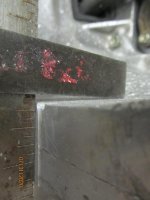

I apologize but I have tried to search for this with no luck. I think, not too long ago, someone posted about drilling a hole in the bottom of the Smitty bell housing similar to what was done on our original gearboxes to allow oil to drain. I am looking for some information on the best place to drill that hole. Perhaps I have the wrong Forum/email list, not sure. Can anyone here help me with what I am looking for?

Thanks,

Lin

Thanks,

Lin

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>