Offline

Hi all,

I am near completion on my TR4A assembly, crossing off the last items on the “to-do list”. My throttle linkage is a bit sticky. If I push the accelerator pedal, it does not (always) return.

I have not yet debugged the problem. (I replaced the bushings and three springs with new during assembly.) I plan to take apart one joint at a time and see where the “sticky bit” is; hopefully I can isolate it to one joint, not several.

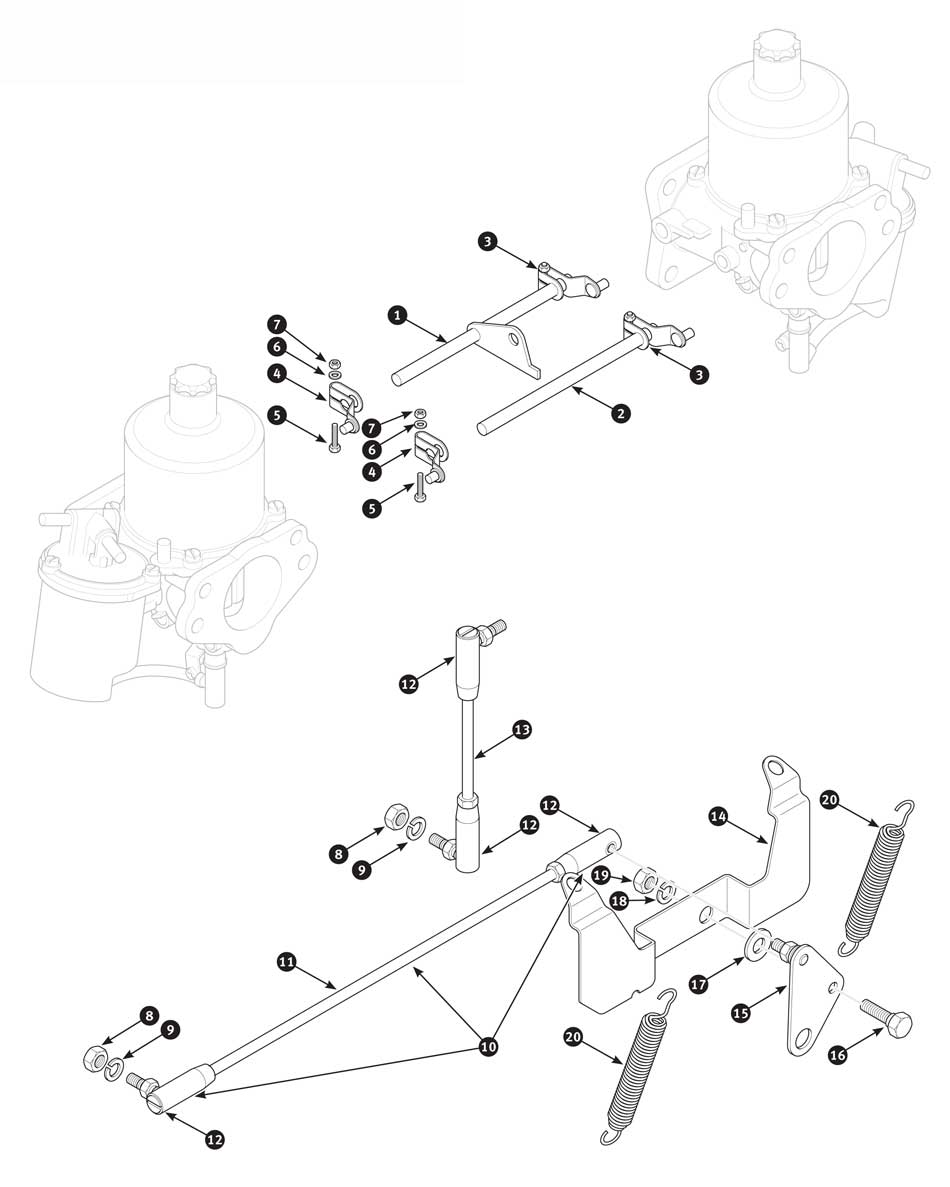

However: what is the correct procedure for installing the adjustable links? Parts 14 and 145077, parts #10 and 13 in attached image. They thread into a mating piece, and a lockwasher plus nut are threaded on. Should the threaded part be screwed tightly to the mating part, followed by a tight nut? Or should the threaded part only be tightened a little, allowing space between the moving surfaces and the nut used as a locknut?

Also, I assume the ball joints in the links should be lubricated? (With graphite??)

(SU HS6 carbs)

thanks!

I am near completion on my TR4A assembly, crossing off the last items on the “to-do list”. My throttle linkage is a bit sticky. If I push the accelerator pedal, it does not (always) return.

I have not yet debugged the problem. (I replaced the bushings and three springs with new during assembly.) I plan to take apart one joint at a time and see where the “sticky bit” is; hopefully I can isolate it to one joint, not several.

However: what is the correct procedure for installing the adjustable links? Parts 14 and 145077, parts #10 and 13 in attached image. They thread into a mating piece, and a lockwasher plus nut are threaded on. Should the threaded part be screwed tightly to the mating part, followed by a tight nut? Or should the threaded part only be tightened a little, allowing space between the moving surfaces and the nut used as a locknut?

Also, I assume the ball joints in the links should be lubricated? (With graphite??)

(SU HS6 carbs)

thanks!

Last edited:

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>