richberman

Jedi Warrior

Offline

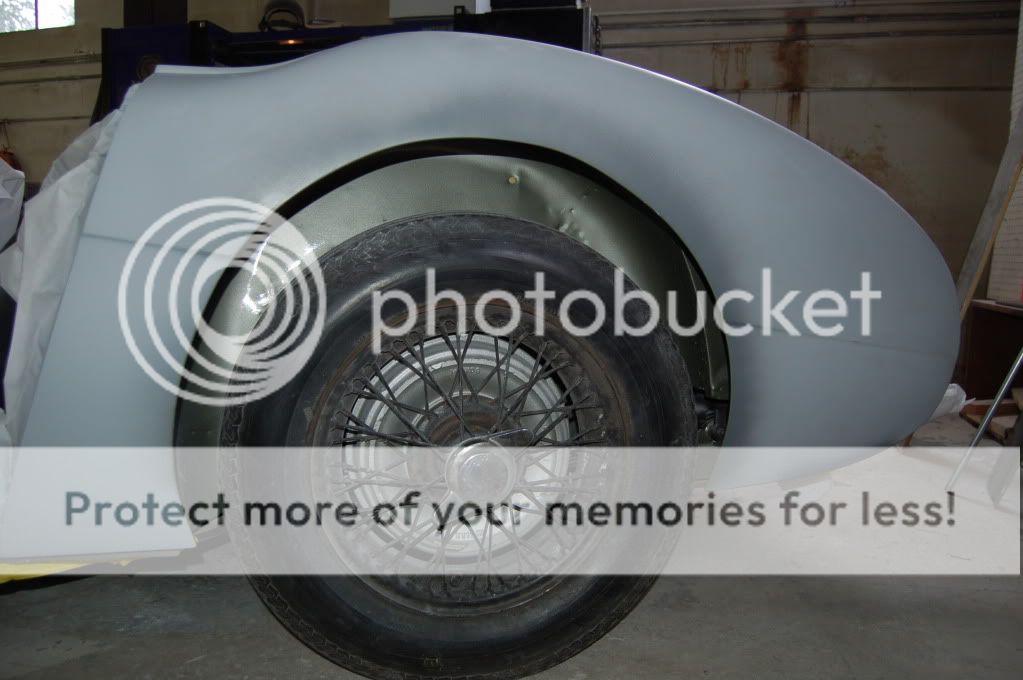

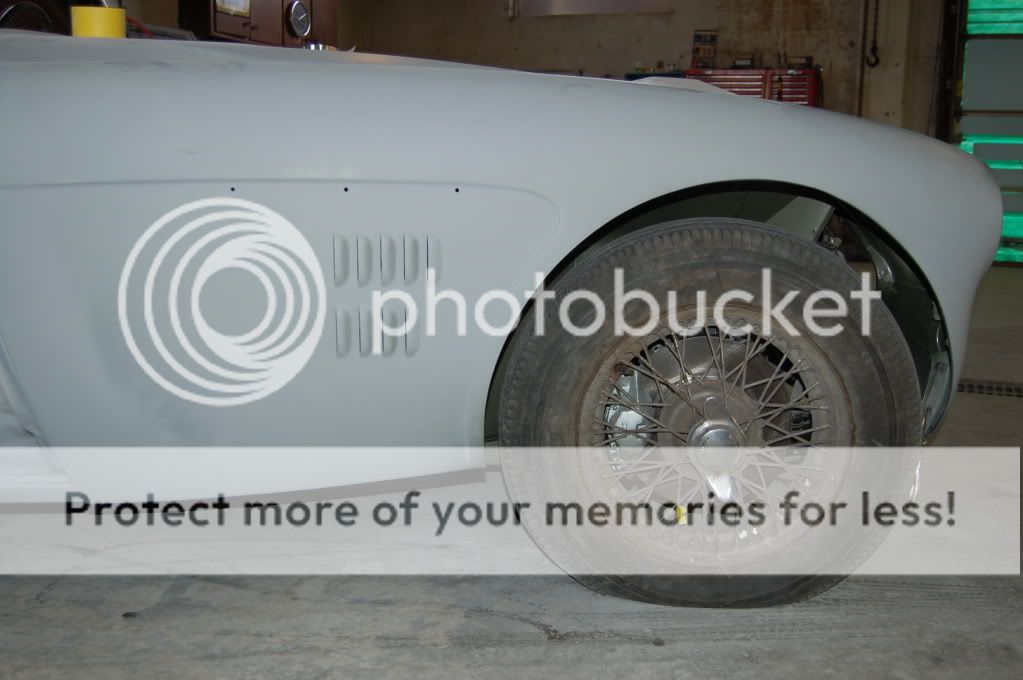

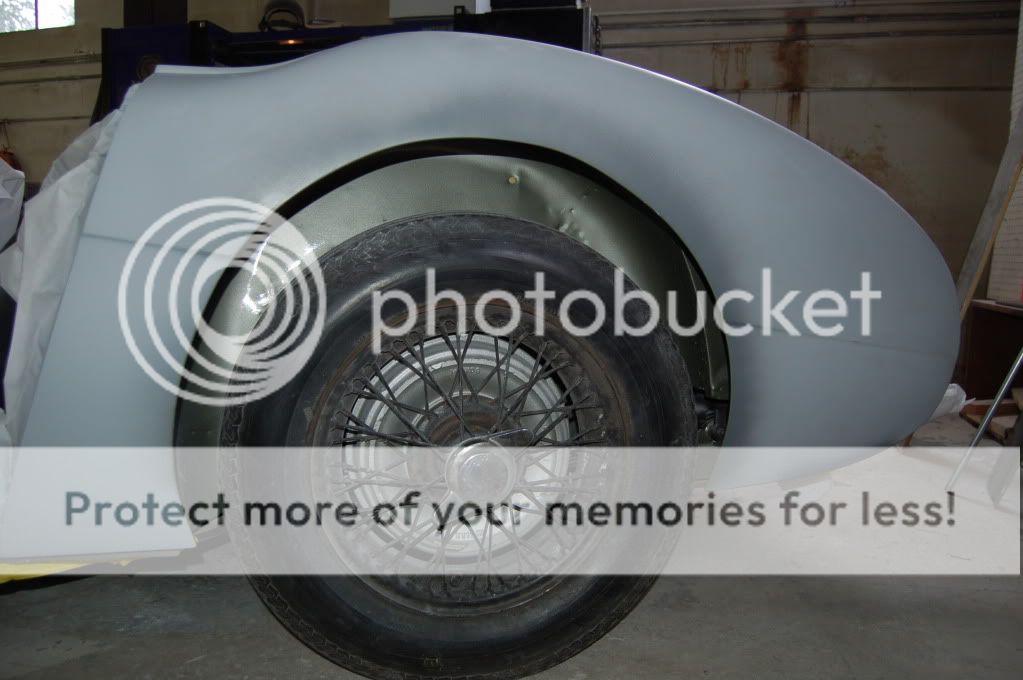

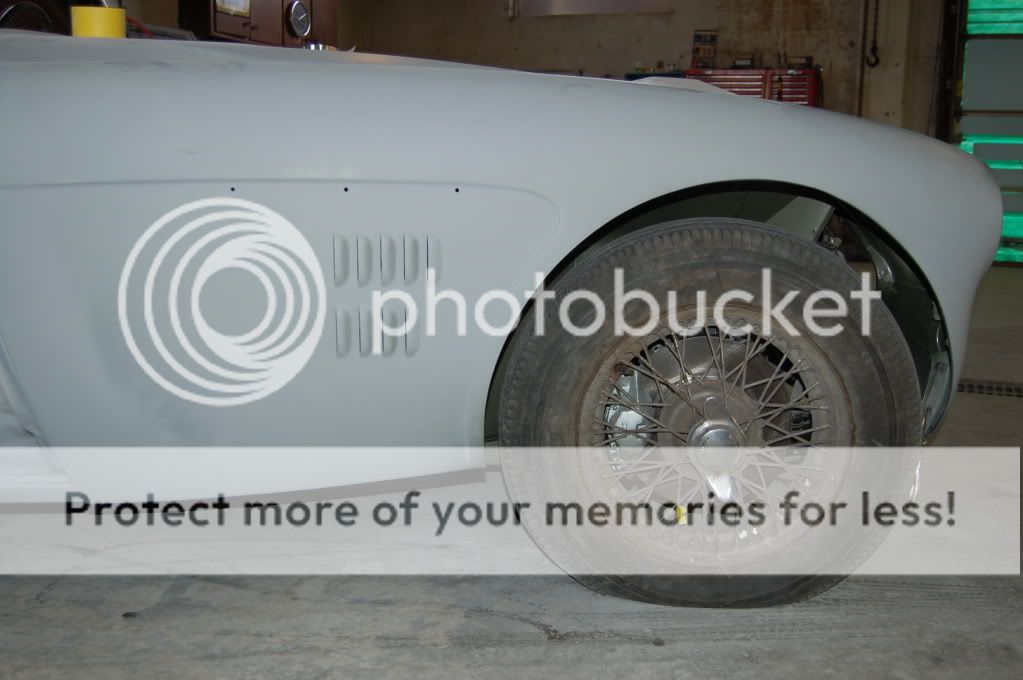

Well I got to see my car today at the bodyshop and I noticed that that the car tires did not seem to fit symmetrically in the wheel wells. When I backed up I noticed that the car sits up higher on the entire left side. I know the frame was straight because I had it checked at that stage. I had the rear springs checked as well. I know the tires on the right are flatter but even when we filled them it still cants. I looked under the rear end and noticed that the rear axle case sits about 1" above the frame cross member on the right but only 1/4"-1/2" on the left. Did I connect the rear springs wrong? What should I check?

Thanks.

Rich

Thanks.

Rich

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>