srvtribute

Member

Offline

PHOTO ATTACHED

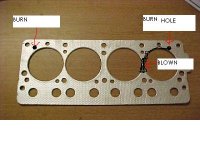

Here we go.. I assembled, torqued etc. Car ran MINT, 4 times around the block then lost cylinders 3+4 again. I disassembled the head again. Blown gasket in between 3+4 just like the previous time. NOW THE PLOT THICKENS. I compared both blown gaskets and they were identical, with burn marks in the same spot! Now, if you're leaning on the driver side fender and looking at the engine, there is a hole in the engine block at about 1 o'clock in relation to the #4 cylinder which doesn't seem to go anywhere, yet is blocked off by the head gasket. Both times the head gasket had a hole burned through it in that spot. before I reassembled the head, I assumed that this hole was an antifreeze port and there was antifreeze left in the hole before assembly. Could it be possible that the coolant in the hole boiled and blew the gasket?? HELP-

PHOTO ATTACHED

Here we go.. I assembled, torqued etc. Car ran MINT, 4 times around the block then lost cylinders 3+4 again. I disassembled the head again. Blown gasket in between 3+4 just like the previous time. NOW THE PLOT THICKENS. I compared both blown gaskets and they were identical, with burn marks in the same spot! Now, if you're leaning on the driver side fender and looking at the engine, there is a hole in the engine block at about 1 o'clock in relation to the #4 cylinder which doesn't seem to go anywhere, yet is blocked off by the head gasket. Both times the head gasket had a hole burned through it in that spot. before I reassembled the head, I assumed that this hole was an antifreeze port and there was antifreeze left in the hole before assembly. Could it be possible that the coolant in the hole boiled and blew the gasket?? HELP-

PHOTO ATTACHED

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>