TimK

Jedi Knight

Offline

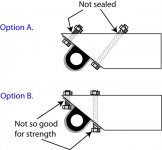

My front anti-sway bar has two brackets with rotted rubber bushings. The brackets are held on with 2 bolts each that go into a box frame member. There must be welded nuts inside, but they are no longer welded. The bolts just turn without unscrewing. The only thing I can think of is cutting off the bolt heads and drilling all the way up through the top of the boxed frame and installing longer bolts with nuts on the top of the frame section. The cutoff bolts and nuts would end up rattling around inside the frame member, I guess.... :frown:

Any better ideas?

Any better ideas?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>