Adnausum, Jeff.

Pulled the master side clyinder out, found three of the small holes in the piston with crap in them and also a bit of crap when I pumped out the MC into a bucket with a towel in the bottom. The tube to the slave seemed clear.

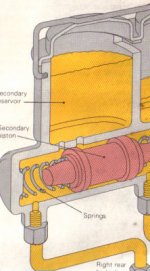

Now, there are two holes in the MC from the top into the piston chamber. One large and one small, the large to the front of the car. It looks like the small one charges the piston/line and the large one is a bypass for what ever gets by the piston seal??

No clue what to do else. Nor any real idea as to just exactly where the piston should be in relation to the holes when put back together. However, at rest I think both of those holes should be open to the piston chamber ie not covered.

Seem right??

Intresting how that works when you think about it, simple, it just moves a fluid column back and forth unlike the brake side which has pressure on it all the time. No wonder it can be difficult to bleed.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>