Offline

Hello all,

I'm a lucky guy: my wife's grandmother found a spot weld gun at the Ft. Myers flea market, which she gave me for Christmas. (I knew my wife was a good catch, but who knew her grandmother would be too!!)

It does not come with directions, however I found the same at Eastwood:

https://www.eastwoodco.com/jump.jsp?itemID=1227&itemType=PRODUCT

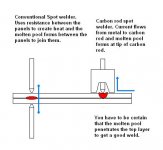

Does anyone have any experience with these? Tips to give? Do thise welders provide quality spot welds? The one concern I have is the welder pushes from one side, to use it properly there needs to be some sort of support from the back.

Baiscally, I would need an arc welder to use it. I have a Hobart 140 MIG welder, so I would buy a cheapie stick welder off Craig's list. Before I do that, is the tool worthy?

Thanks,

Mike

66 TR4A

I'm a lucky guy: my wife's grandmother found a spot weld gun at the Ft. Myers flea market, which she gave me for Christmas. (I knew my wife was a good catch, but who knew her grandmother would be too!!)

It does not come with directions, however I found the same at Eastwood:

https://www.eastwoodco.com/jump.jsp?itemID=1227&itemType=PRODUCT

Does anyone have any experience with these? Tips to give? Do thise welders provide quality spot welds? The one concern I have is the welder pushes from one side, to use it properly there needs to be some sort of support from the back.

Baiscally, I would need an arc welder to use it. I have a Hobart 140 MIG welder, so I would buy a cheapie stick welder off Craig's list. Before I do that, is the tool worthy?

Thanks,

Mike

66 TR4A

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>