AHS

Senior Member

Offline

Hi, I recently did a little modification to a BT7 side shift gearbox and was wondering if anyone else has experienced or fixed a similar problem. Hopefully this post will help someone else too.

The problem is when shifting into 2nd gear, the shift lever could overtravel just a little but and move the slider just enough to rub on the next gear and make a nasty grinding sound. Once you let go of the shift lever, it fell into the detent and you could drive fine with no noise whatsoever. If you were very delicate shifting slowly into 2ng gear until you feel the detent, it could be done noiselessly, but that's no fun. Another gearbox I know doesn't do the same thing at all, so maybe most don't.

So while I was replacing the carpet I decided I might as well replace the clutch and then open up the gearbox, the way things generally tend to get out of control. Since the shift rod slides forward for 2nd gear, I was able to make a sleeve to slip over the front of the rod that hits against the inside of the case and stops forward travel just about .010" farther than it needs to go to slide into the detent. Sorry I forget the exact dimension, but I may have it written in my book if you want to know. It should be shortened to fit exactly right and this is actually the 2nd one I made, the first time I cut a little too short and started over.

I know that the depth of the shift rod recess in the bellhousing also provides a limit to the forward travel, but my my measurements, it is way too deep to do any good.

While I was at it I also made a spacer to limit the 4th gear travel even though the gearbox had no overtravel problem for 4th. This spacer hits on a portion of the inside of the case that is half as-cast and half machined flat, so it may not work as well as the second gear travel limiter that hits only a machined surface. But I figured this modification can't cause any harm, and I really didn't want to find out later that I should have done the same for 4th gear given the short time it took to make.

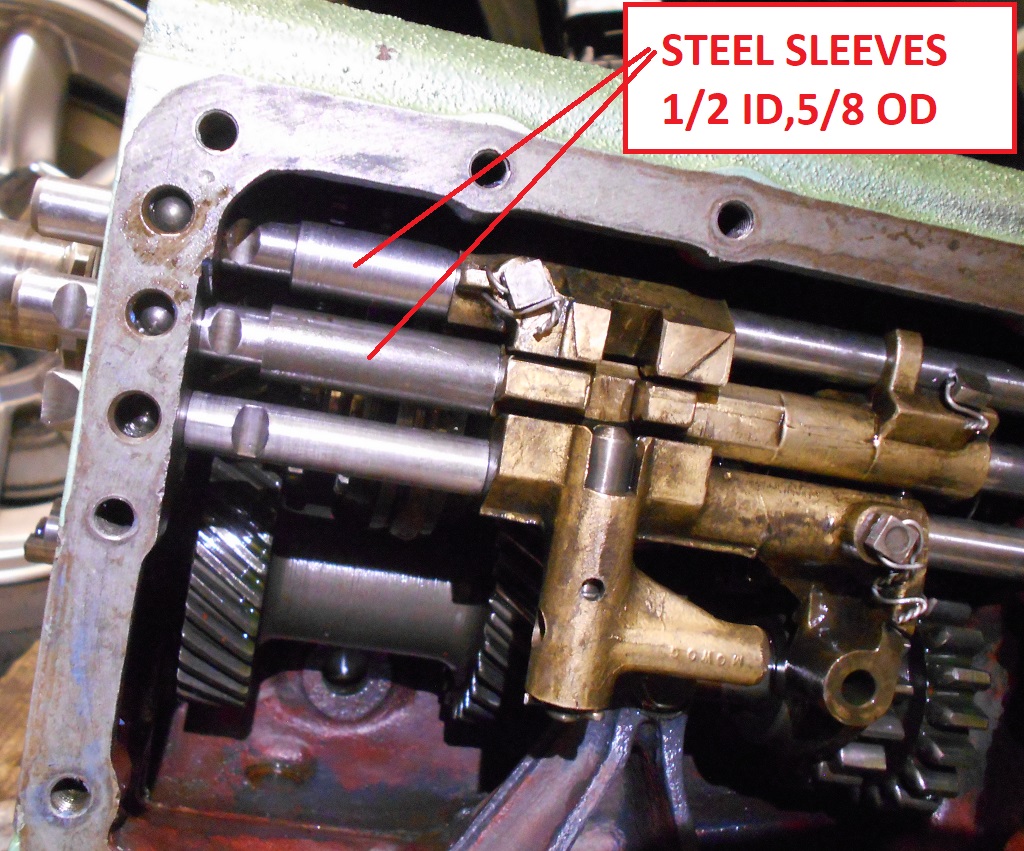

Bottom line - it made the car much more pleasant to drive. No more worries about very delicate shifts into 2nd gear. Of course if you make these, the ends must be perfectly square. I used a lathe, but that's not the only way. You must keep shortening them until just a tiny bit more (I did .010") than the entire detent notch is visible when you look straight into the detent ball hole while in 2nd gear position. Also test with the detent ball and spring in place with pressure on the spring to make sure it seats solidly into 2nd & 4th gear positions. The picture below shows neutral position, and you can see the 2nd and 4th gear detent notches inside the case opening.

The steel sleeves are free to slide around, and are a small enough OD that they don't cause any harm with shifting into any other position. 5/8" OD works, or maybe it could be a tiny bit bigger. 3/4" won't work, unless machined thinner in the portion where the shift rods need to clear the other forks in certain positions.

The problem is when shifting into 2nd gear, the shift lever could overtravel just a little but and move the slider just enough to rub on the next gear and make a nasty grinding sound. Once you let go of the shift lever, it fell into the detent and you could drive fine with no noise whatsoever. If you were very delicate shifting slowly into 2ng gear until you feel the detent, it could be done noiselessly, but that's no fun. Another gearbox I know doesn't do the same thing at all, so maybe most don't.

So while I was replacing the carpet I decided I might as well replace the clutch and then open up the gearbox, the way things generally tend to get out of control. Since the shift rod slides forward for 2nd gear, I was able to make a sleeve to slip over the front of the rod that hits against the inside of the case and stops forward travel just about .010" farther than it needs to go to slide into the detent. Sorry I forget the exact dimension, but I may have it written in my book if you want to know. It should be shortened to fit exactly right and this is actually the 2nd one I made, the first time I cut a little too short and started over.

I know that the depth of the shift rod recess in the bellhousing also provides a limit to the forward travel, but my my measurements, it is way too deep to do any good.

While I was at it I also made a spacer to limit the 4th gear travel even though the gearbox had no overtravel problem for 4th. This spacer hits on a portion of the inside of the case that is half as-cast and half machined flat, so it may not work as well as the second gear travel limiter that hits only a machined surface. But I figured this modification can't cause any harm, and I really didn't want to find out later that I should have done the same for 4th gear given the short time it took to make.

Bottom line - it made the car much more pleasant to drive. No more worries about very delicate shifts into 2nd gear. Of course if you make these, the ends must be perfectly square. I used a lathe, but that's not the only way. You must keep shortening them until just a tiny bit more (I did .010") than the entire detent notch is visible when you look straight into the detent ball hole while in 2nd gear position. Also test with the detent ball and spring in place with pressure on the spring to make sure it seats solidly into 2nd & 4th gear positions. The picture below shows neutral position, and you can see the 2nd and 4th gear detent notches inside the case opening.

The steel sleeves are free to slide around, and are a small enough OD that they don't cause any harm with shifting into any other position. 5/8" OD works, or maybe it could be a tiny bit bigger. 3/4" won't work, unless machined thinner in the portion where the shift rods need to clear the other forks in certain positions.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>