Hi All,

I have found it difficult to find servicers that know and can balance wheels and drums and have heard many glowing comments about Hendrix Wire Wheel. However, since knowledgeable local servicers are disappearing with rapidity, a while back, I decided to experiment with a fixture that could be used to have my rear elements balanced using locally available standard dynamic spin balancers. Additionally, since it would be difficult to apply standard commonly-available weights to balance drums alone, my thought was to balance both drum and wheel as a unit and, therefore, apply a small mark on both to key the alignment of drum and wheel when installing on my Healey.

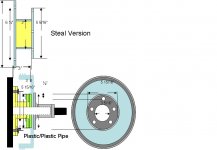

The fixture allows bolting drum and an old rear hub to a flat base plate, if the balancer supports that type of mounting, or a large cone on the in-side and small cone on the outer side of the balancer's bar. The drum would be bolted onto an old wheel hub with the wheel held on the hub with an old spinner that has an appropriately sized hole drilled in it to allow the balancer bar pass through. A small cone would be placed on the bar to center the outer side of the fixture and tightened down in the standard manor. This combination would then be balanced with all necessary weights placed on the wheel. Although this had been successful for me, the wheel must be indexed to the drum as balanced and mounted that way. Additionally, I had inappropriately assumption that the common balance would allow a fixture to be mounted on a flat plate or have a:

1. Long enough mounting pipe.

2. Small mounting cone for centering the loaded fixture through the hole drilled within the Healey spinner.

As always, any suggestions on improving this fixture or modifying the approach, would be appreciated.

Ray(64BJ8P1)

Hi Guest!

Hi Guest!