So, after procrastinating nearly all month, it was finally time to get down to business. This year, the mechanical focus is mainly on the front end -- brake job, replace some of the bushings, rack boots. I only get a chance to work for about an hour at a time, and I'm definitely taking my time, especially with the brakes, since there is no "90% right" when it comes to brakes...and I've never tried brake work before.

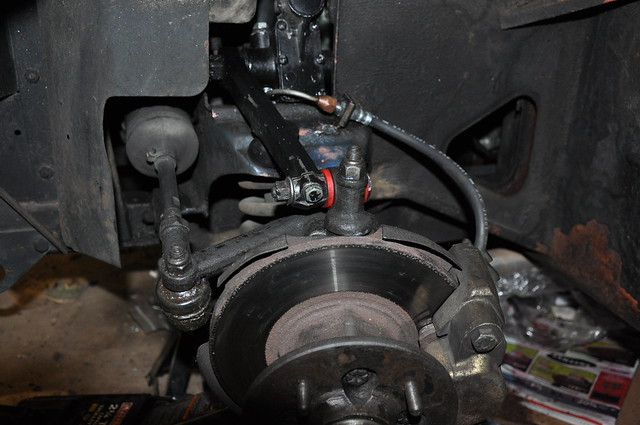

Brake pads out! One these were out, the rotor spun freely, but I hear a bit of bearing clatter, so I imagine I need to repack the wheel bearings.

DSC_0002 by David Cohen, on Flickr

DSC_0002 by David Cohen, on Flickr

Caliper off - I am replacing the brake hoses, too, and will likely pull the rotors, although I don't think they need turning.

DSC_0004 by David Cohen, on Flickr

DSC_0004 by David Cohen, on Flickr

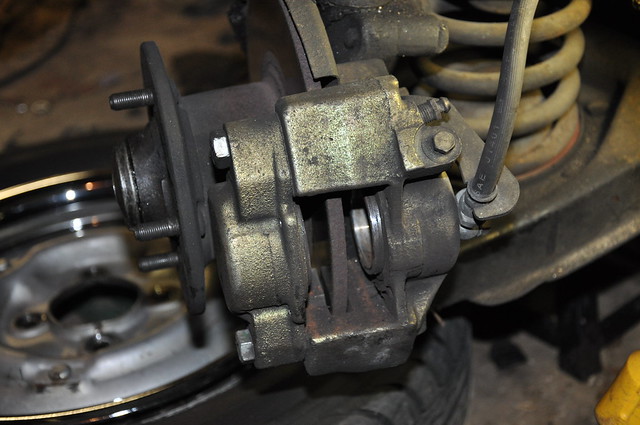

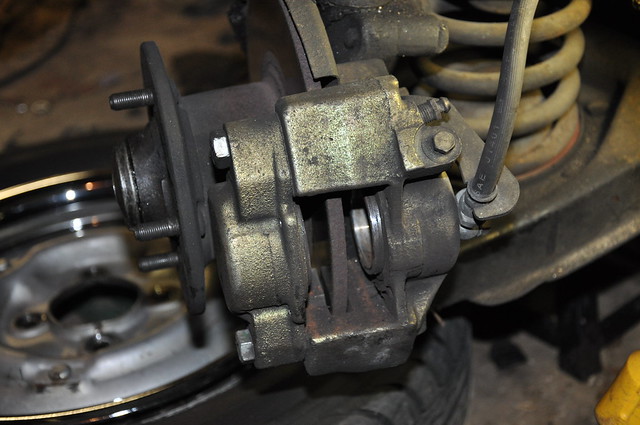

Caliper on the workbench -- I'm cleaning up the parts as I go along. Not going too terribly crazy, but clearing any loose dirt and grime from them

DSC_0005 by David Cohen, on Flickr

DSC_0005 by David Cohen, on Flickr

With the tire off, I cleaned up underneath the wheel well. I was pleasantly surprised to find that it was fairly clean underneath. Looks like someone may have done a rattle can paint job at some point, but the painting underneath seems to be more uniform than that. Overall, once I removed some of the grime, I found the condition to be better than I thought:

DSC_0006 by David Cohen, on Flickr

DSC_0006 by David Cohen, on Flickr

More pics to come as work progresses!

Brake pads out! One these were out, the rotor spun freely, but I hear a bit of bearing clatter, so I imagine I need to repack the wheel bearings.

DSC_0002 by David Cohen, on Flickr

DSC_0002 by David Cohen, on FlickrCaliper off - I am replacing the brake hoses, too, and will likely pull the rotors, although I don't think they need turning.

DSC_0004 by David Cohen, on Flickr

DSC_0004 by David Cohen, on FlickrCaliper on the workbench -- I'm cleaning up the parts as I go along. Not going too terribly crazy, but clearing any loose dirt and grime from them

DSC_0005 by David Cohen, on Flickr

DSC_0005 by David Cohen, on FlickrWith the tire off, I cleaned up underneath the wheel well. I was pleasantly surprised to find that it was fairly clean underneath. Looks like someone may have done a rattle can paint job at some point, but the painting underneath seems to be more uniform than that. Overall, once I removed some of the grime, I found the condition to be better than I thought:

DSC_0006 by David Cohen, on Flickr

DSC_0006 by David Cohen, on FlickrMore pics to come as work progresses!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>