Offline

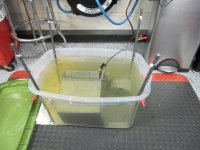

I am trying to do some rust removal on the heater box of my Jaguar MK2 restoration project ( I still love my Healey more!). A Jaguar email lister recommended molasses so I did a little research and I thought I would share two sources with you that may be of interest since we all know how prone Healeys are to rust..

The first one is about molasses and is frankly pretty remarkable if you have the time:

https://blog.1aauto.com/2011/02/21/did-you-know-that-molasses-is-a-rust-remover/

The second is a Hot Rod magazine article comparing many rust removal products, chemical and blasting.

https://www.hotrod.com/techarticles/body/hrdp_0901_rust_removal_guide/viewall.html

Whether you need to use any of these products or not, I think you will find the short articles of interest.

Lin

Lin Rose

1959 AN5 Bugeye - pure driving enjoyment, go-kart with a body.

1960 BT7 "The Bloody Beast" - owned since 1971, my first car and still have it!

1964 Jag MKII - current project

The first one is about molasses and is frankly pretty remarkable if you have the time:

https://blog.1aauto.com/2011/02/21/did-you-know-that-molasses-is-a-rust-remover/

The second is a Hot Rod magazine article comparing many rust removal products, chemical and blasting.

https://www.hotrod.com/techarticles/body/hrdp_0901_rust_removal_guide/viewall.html

Whether you need to use any of these products or not, I think you will find the short articles of interest.

Lin

Lin Rose

1959 AN5 Bugeye - pure driving enjoyment, go-kart with a body.

1960 BT7 "The Bloody Beast" - owned since 1971, my first car and still have it!

1964 Jag MKII - current project

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>