Paul Slice

Jedi Hopeful

Offline

DJThom,

On the 78 the origional plan was to paint the rubber bumpers body color, like Paul is talking about, untill I removed them and realized just how heavy that they feel. Once off they were never reinstalled and 4 years later I would without hesitation do the mod again.

The top of the grill and the bottom of the hoods(bonnet) fitment is very hard to get correct but does not show much when the car is finished and painted, the turn signal placement is also critical to the looks of the finished product.

The Sebring panels you are using will look great but I was lazy and used the Fibreglass spoiler bumper which required no bodywork except mounting the indicator lights.

The best part is that after it is completed you can sit nearby at car shows and watch the faces of the people as they walk by your car, some will love it others will look like they have a sudden need to use the portajohn /bcforum/images/%%GRAEMLIN_URL%%/smile.gif

Good luck,

Paul S

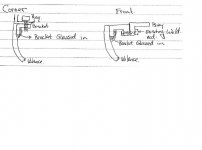

my rubber bumperless 78

On the 78 the origional plan was to paint the rubber bumpers body color, like Paul is talking about, untill I removed them and realized just how heavy that they feel. Once off they were never reinstalled and 4 years later I would without hesitation do the mod again.

The top of the grill and the bottom of the hoods(bonnet) fitment is very hard to get correct but does not show much when the car is finished and painted, the turn signal placement is also critical to the looks of the finished product.

The Sebring panels you are using will look great but I was lazy and used the Fibreglass spoiler bumper which required no bodywork except mounting the indicator lights.

The best part is that after it is completed you can sit nearby at car shows and watch the faces of the people as they walk by your car, some will love it others will look like they have a sudden need to use the portajohn /bcforum/images/%%GRAEMLIN_URL%%/smile.gif

Good luck,

Paul S

my rubber bumperless 78

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>