Dadandson said:

So then the second number is a percentage of increase by moving the fulcrum?

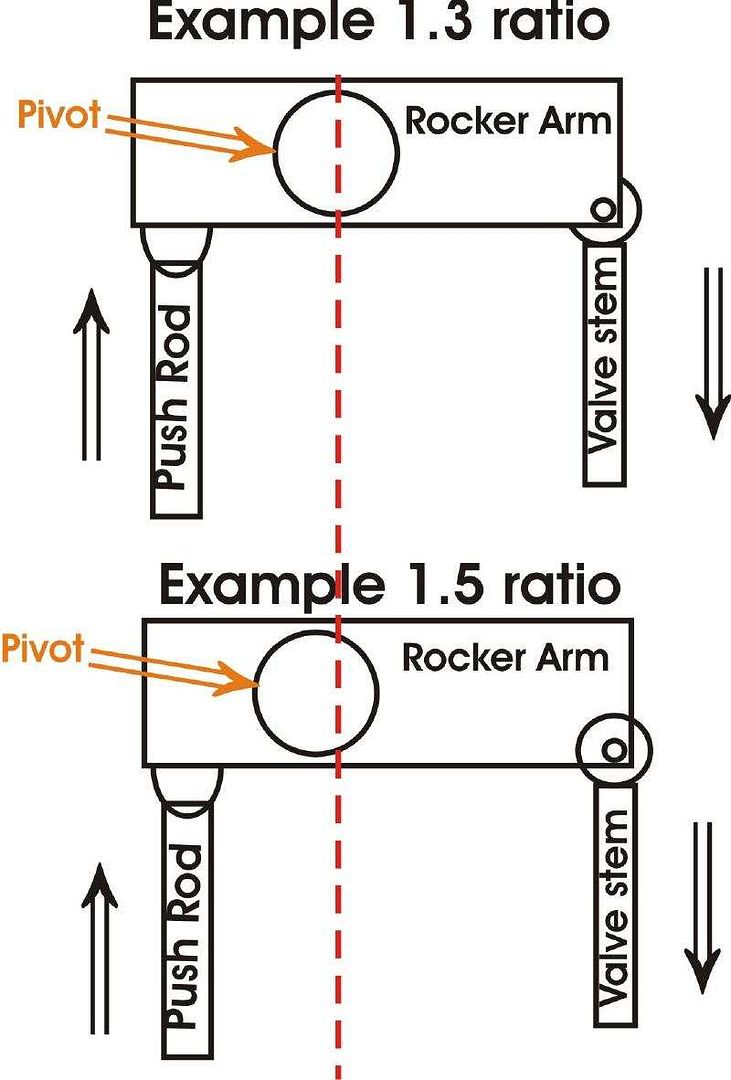

Yes and this has to happen at the shaft, that why when significent ratio changes are made the pedestal holes must change. Titan rocker 1.5 ratio sets for example come with new pedestals, and the HS 1.3 units mess up the geomentry, and cause pushrod interference

I throw this in as well, since a roacker arms moves in a arc, and most engineers fiquire ratios horizontally, then almost all rocker arms lose ratio thru the arc, the more they depress the valve the more ratio is lost, and of course then most of us go out and get a higher lift cams so we lose even m more ratio, if the high lift cam lifts enough, sure we see a gain, but the ratio loss rate is enlarging the more we lift. The real rick is to get a racker that stay true to it's claim thru out the lift, Keith Dodds forged rocker are the only one I know that does.

Tim you can fiquire out your 'real" ratio of your rockers, by simply throwing ratio at them x cam lobe lift, until the applied ratio x cam lobe lift matches te actual measurement you are seeing in cam lift measured at the valve.

Amazing feat by the way Tim, but I think you can even further develop it, and come up with something people will buy. I like to talk to you more about this, and maybe lead you to someone that could be even more help in the etire theory of this. I have no idea if you just wanred to make a set of racker for yourslef, or if you wantto get into the rocker arm business, but if it's the later, then I have some builders that would love to talk to you in the development stages. Call me or PM me anmber wher I can reach you, all my contact info is on my website. Thanks.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<