aeronca65t

Great Pumpkin

Offline

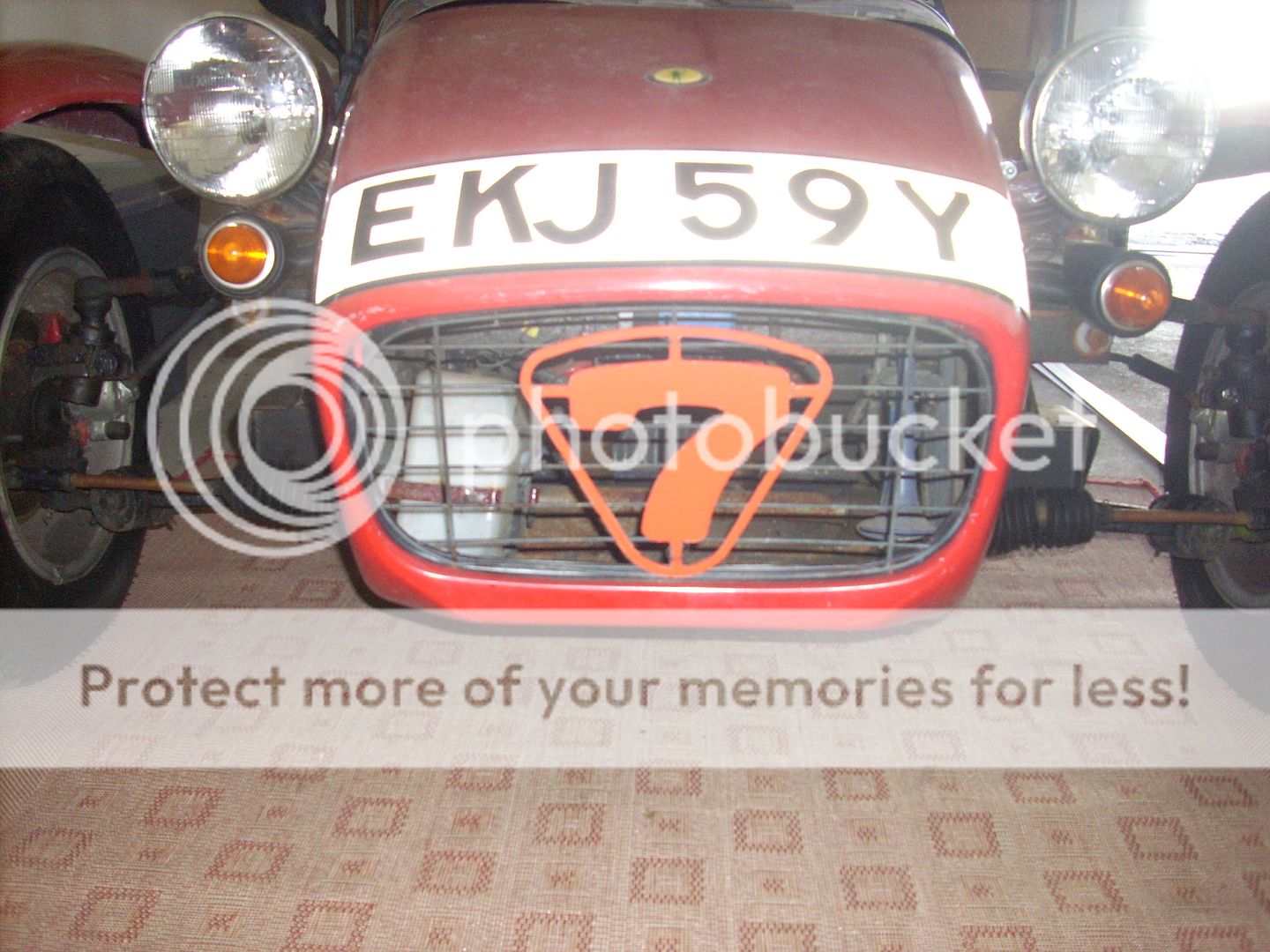

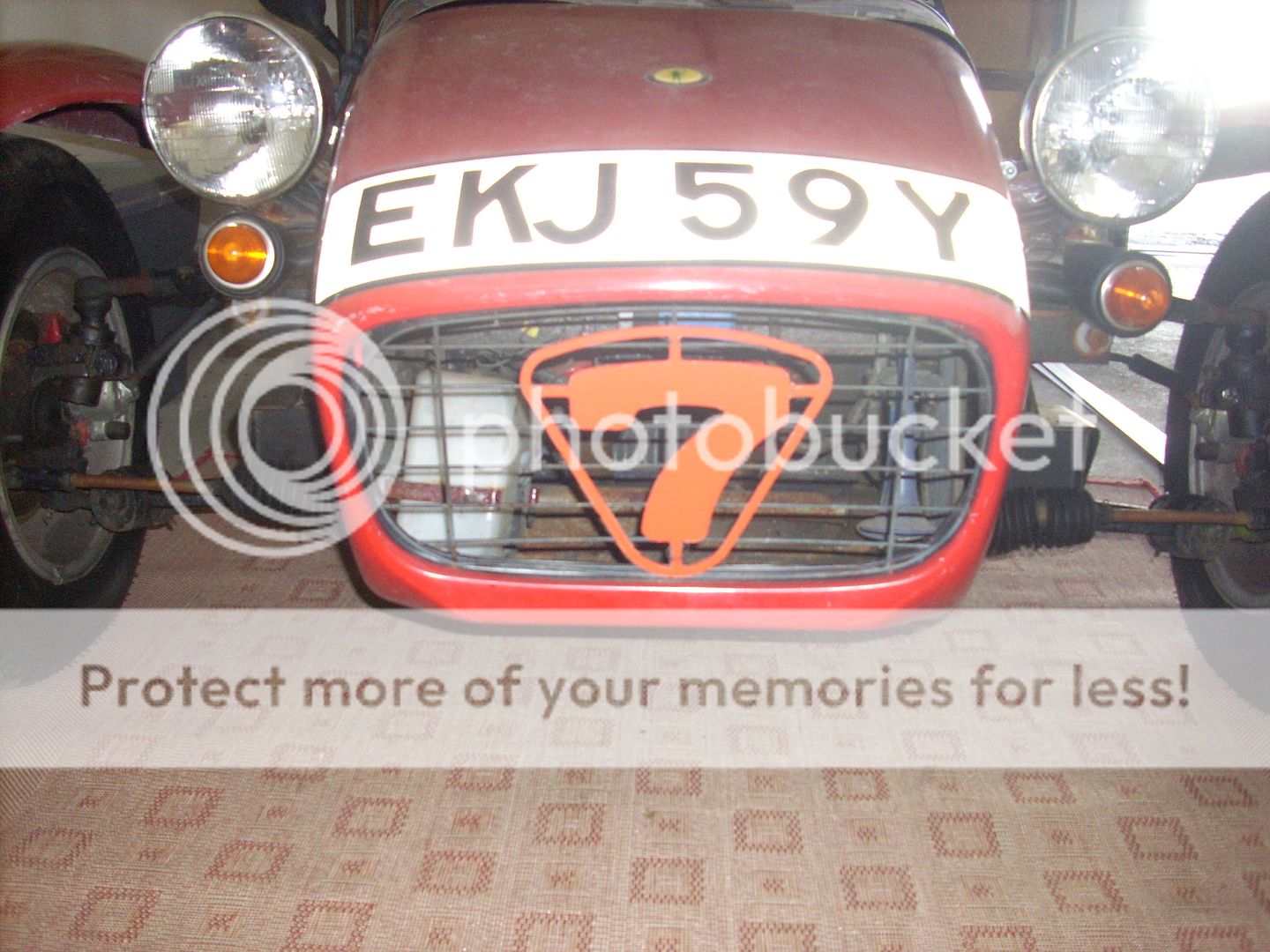

One of the details I like on the various, modern versions of the Lotus 7 is the large "7" in the grill. I think this is a Caterham design. In any event, I think it looks pretty fetching.

Especially since I could probably make one (I looked on eBay UK....they're not cheap).

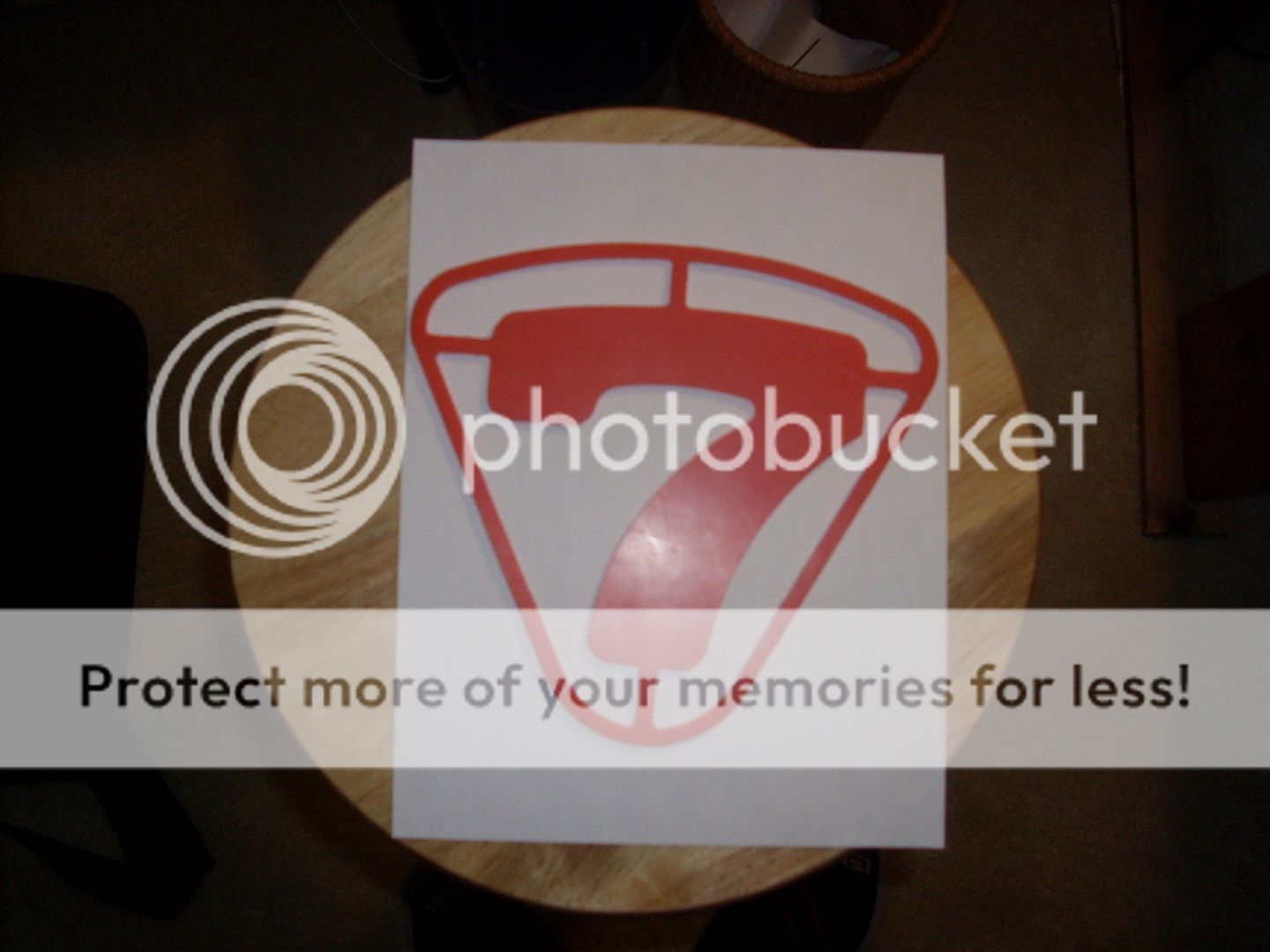

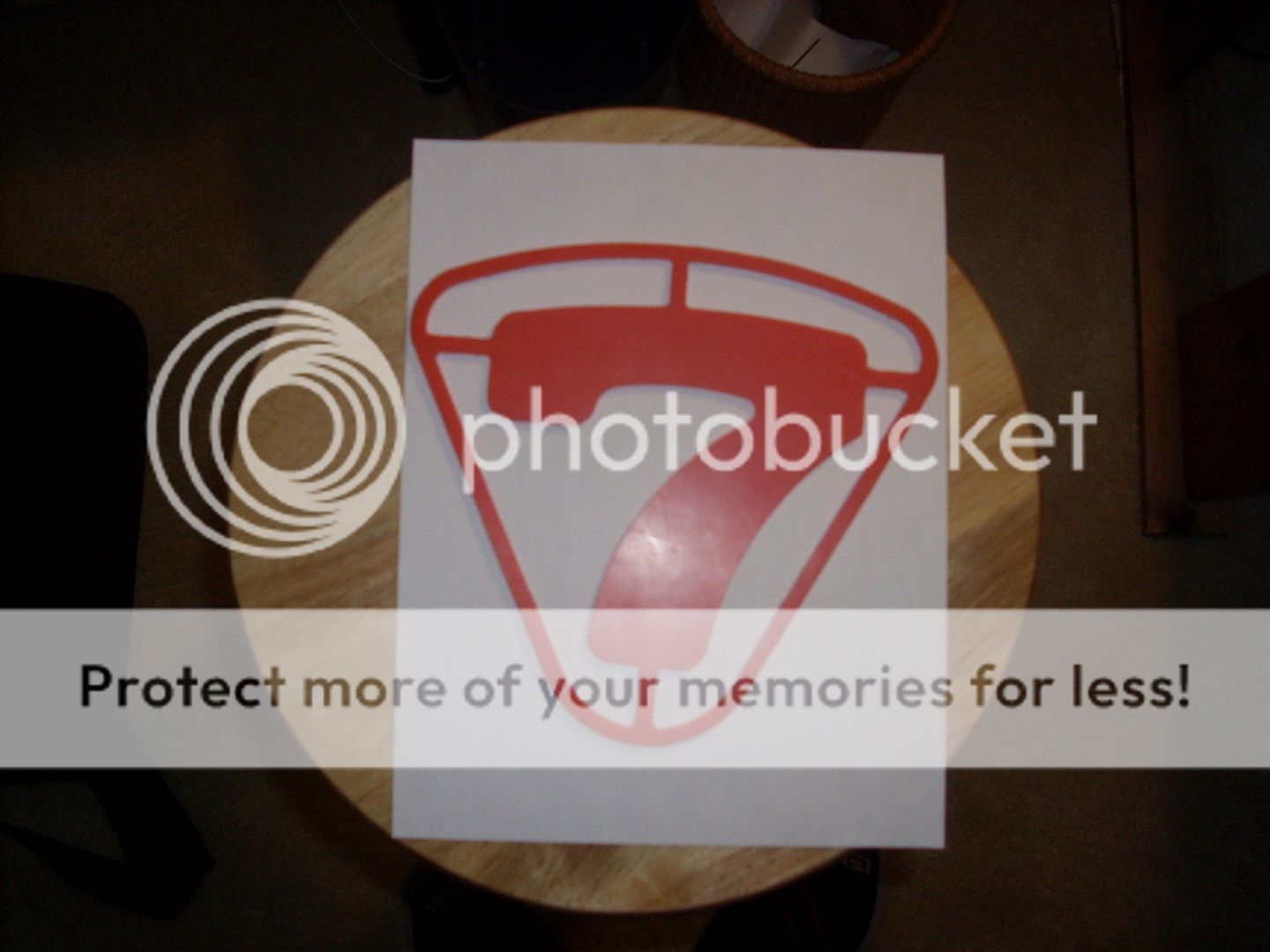

I began by saving a picture of this design by searching Google Images.

Once a jpg. image was saved, I processed the photo through WInTopo which is a free raster to vector software convertor. In other words, it converts a photo image (such as ".jpg") to a CAD format (such as ".dxf").

After cleaning up the CAD drawing and scaling it to an appropriate size, I post-processed the geometry to convert it to CNC code. I used PowerStation (not free....we use it at work).

The CNC code required a little de-bugging but otherwise looked good.

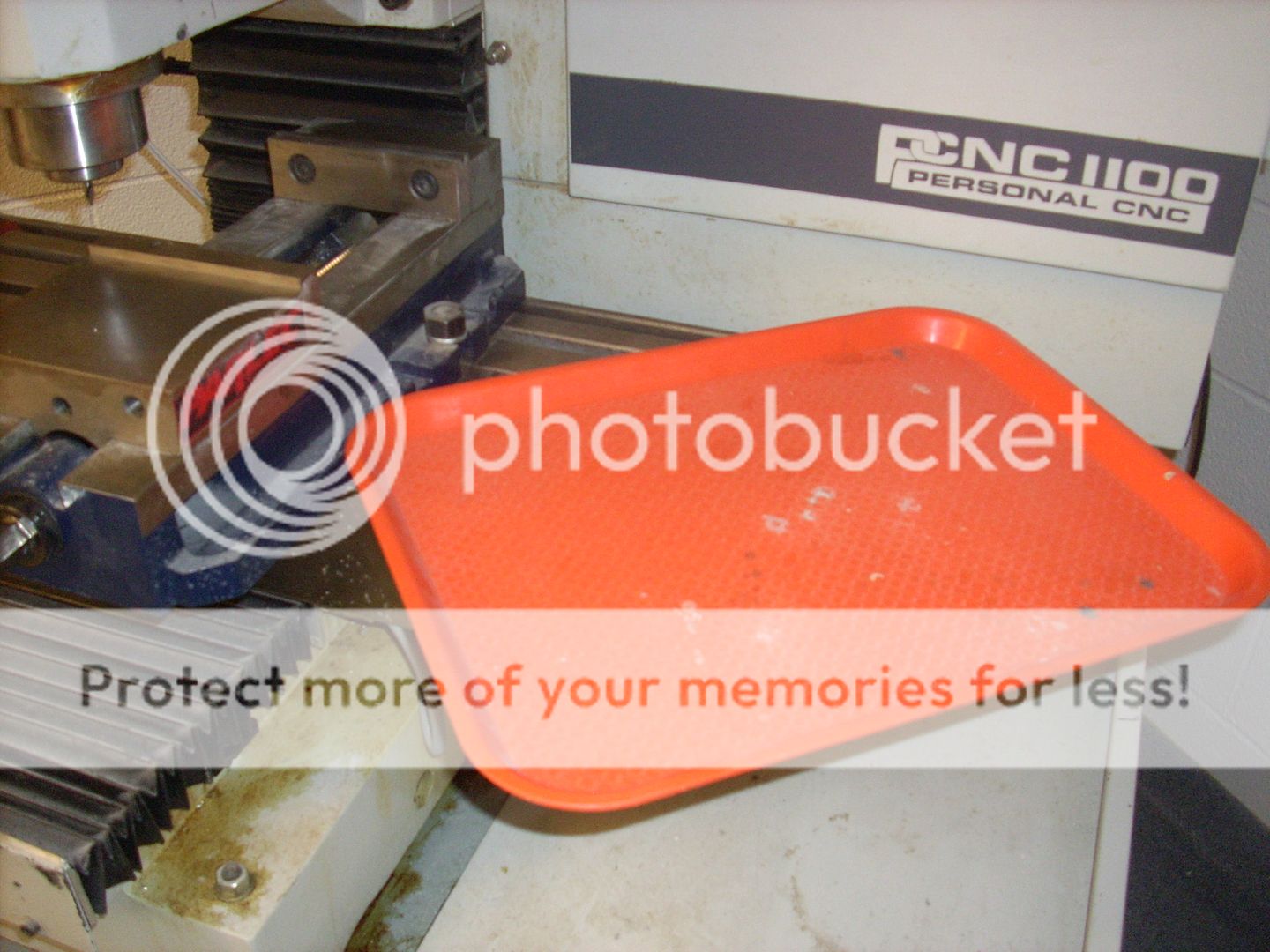

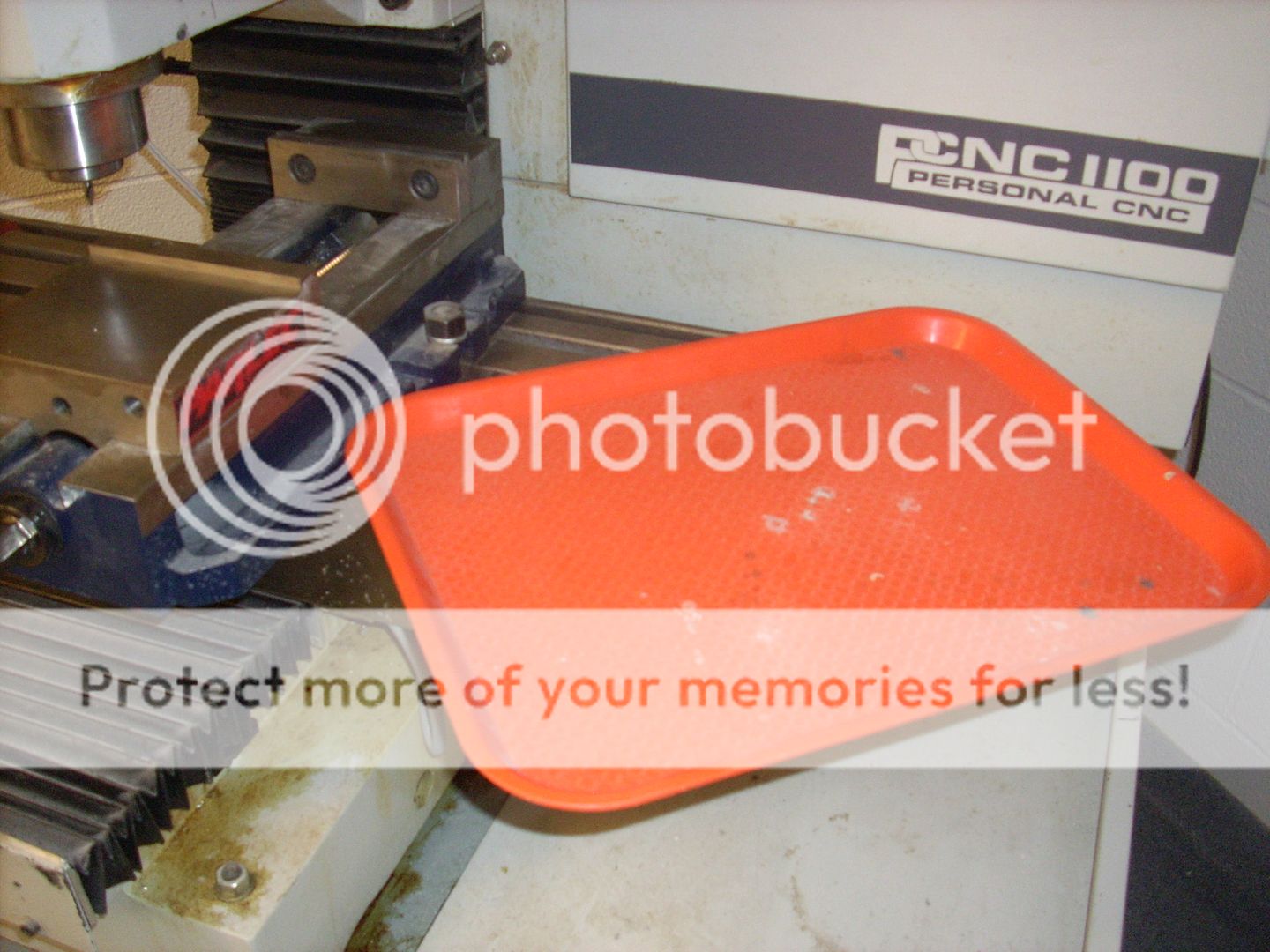

I wondered what to do a test cut on? Then I remembered we had some old cafeteria trays laying around (our cafe got rid of all their trays a few years ago). So I screwed a tray to a piece of plywood and clamped the plywood into the vise on our Tormach CNC mill. I used a 3/16" two flute mill running about 2000 rpm at around 10 ipm. The result wasn't too bad.

So I cut another one out of a piece of scrap aluminum (also screwed to the plywood). It's the last photo below.

I may make a third one (the aluminum one is made out of pretty thin scrap). But anyway, you get the idea in the pictures below.

~WinTopo freeware~

~PowerStation free demo~

~Tormach 1100 CNC mill~

Especially since I could probably make one (I looked on eBay UK....they're not cheap).

I began by saving a picture of this design by searching Google Images.

Once a jpg. image was saved, I processed the photo through WInTopo which is a free raster to vector software convertor. In other words, it converts a photo image (such as ".jpg") to a CAD format (such as ".dxf").

After cleaning up the CAD drawing and scaling it to an appropriate size, I post-processed the geometry to convert it to CNC code. I used PowerStation (not free....we use it at work).

The CNC code required a little de-bugging but otherwise looked good.

I wondered what to do a test cut on? Then I remembered we had some old cafeteria trays laying around (our cafe got rid of all their trays a few years ago). So I screwed a tray to a piece of plywood and clamped the plywood into the vise on our Tormach CNC mill. I used a 3/16" two flute mill running about 2000 rpm at around 10 ipm. The result wasn't too bad.

So I cut another one out of a piece of scrap aluminum (also screwed to the plywood). It's the last photo below.

I may make a third one (the aluminum one is made out of pretty thin scrap). But anyway, you get the idea in the pictures below.

~WinTopo freeware~

~PowerStation free demo~

~Tormach 1100 CNC mill~

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>