-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacing the crankshaft damper [harmonic balancer]

- Thread starter pschauss

- Start date

Keoke

Great Pumpkin

Offline

I need to replace the crankshaft balancer. OK!

Can this be done with the engine in the car?----? YES

do I need to at least lift it a bit off of the motor mounts? ------> YES

What is the best kind of puller to use for this job?----> Shortest Three legged one you have that will grab it.

AS BOB Noted:

Your biggest problem will be getting the large nut off the balancer/pulley. .----> Here My Impact wrench worked a treat.

Can this be done with the engine in the car?----? YES

do I need to at least lift it a bit off of the motor mounts? ------> YES

What is the best kind of puller to use for this job?----> Shortest Three legged one you have that will grab it.

AS BOB Noted:

Your biggest problem will be getting the large nut off the balancer/pulley. .----> Here My Impact wrench worked a treat.

Last edited:

Bob_Spidell

Yoda

Offline

I did this a couple years ago. Yes, you have to unbolt the motor mounts (easiest at the chassis). You also have to disconnect the throttle shaft on the engine and the tie rod on the OD. I lifted the engine with a floor jack and a 2x4 under the pan, which left a nice impression of the 2x4 on the pan (didn't cause any problems, though).

Your biggest problem will be getting the large nut off the balancer/pulley. You have to 'lock up' the engine and use a) a large breaker bar and socket b) the starter or c) a 3/4" impact wrench which doesn't really fit between the balancer and the front chassis cross-connect. (a) and (b) didn't work for me, but (c) did with some finagling. If your water pump has 50K or more miles on it you should consider replacing it while you're at it, but I dunno a reliable source for a new one (Michael Salter does good rebuilds). Check your timing cover seal--you'll want a new one with a new/rebuilt balancer--and timing chain tensioner while you're at it.

Why are you replacing the balancer? They can be rebuilt.

Your biggest problem will be getting the large nut off the balancer/pulley. You have to 'lock up' the engine and use a) a large breaker bar and socket b) the starter or c) a 3/4" impact wrench which doesn't really fit between the balancer and the front chassis cross-connect. (a) and (b) didn't work for me, but (c) did with some finagling. If your water pump has 50K or more miles on it you should consider replacing it while you're at it, but I dunno a reliable source for a new one (Michael Salter does good rebuilds). Check your timing cover seal--you'll want a new one with a new/rebuilt balancer--and timing chain tensioner while you're at it.

Why are you replacing the balancer? They can be rebuilt.

Randy Forbes

Yoda

Offline

1-11/16"

Offline

With a BJ7, you should be able to unbolt the balancer from the pulley without removing the pulley -- if you don't want to do the other stuff as is recommended above.

I did this last time and sent my damper out to Damper Dudes to be rebuilt - quite reasonable.

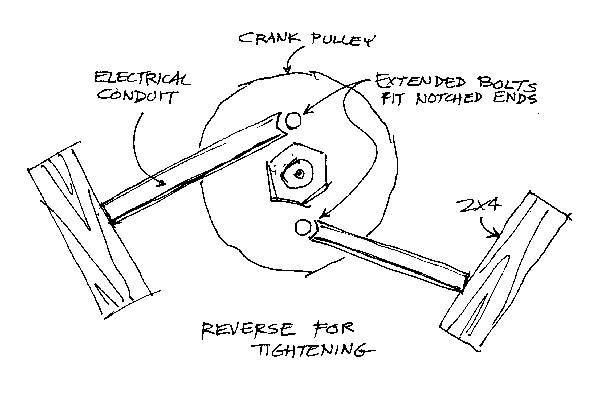

I used this setup to lock the crank:

I did this last time and sent my damper out to Damper Dudes to be rebuilt - quite reasonable.

I used this setup to lock the crank:

Keoke

Great Pumpkin

Offline

Ok. I have the engine raised enough to get the socket on the nut but the impact wrench does not budge the crankshaft nut. It is a right hand thread isn't it?

Thanks

I think SO been a while,but Impact wrench I used had a torque of 300 pounds or so!-??

Thanks for all of the advice. One of the engineers I work with suggested that I might need more airflow to my impact wrench. He suggested that I increase the pressure at the tank by 10 psi to compensate for the fact that I was using a 3/8" hose instead of 1/2". I had to let the impact wrench hammer on the nut for a few minutes but it finally broke it loose.

Since my gear puller removed damper and the pulley together I am going to replace the front seal while I have access to it. Can this be done without removing the timing chain cover?

Peter

1963 BJ7

Since my gear puller removed damper and the pulley together I am going to replace the front seal while I have access to it. Can this be done without removing the timing chain cover?

Peter

1963 BJ7

RestoreThemAll

Jedi Warrior

Offline

Why not at least inspect the timing chain/gear/guide/tensioner? You're almost there. Also, you might take a close look at the crank shaft snout. Mine needed a little cleaning up. It was a little rough around the seal area. Not concerning but I bet it would have leaked if it were left that way. That's easier done with the timing chain cover off.

Thanks for all of the suggestions so far. I pulled the timing chain cover and everything in there looked to be in good shape. (The engine has about 30k miles on it since it was rebuilt 19 years ago.)

I successfully installed the combined damper and pulley that I got from Moss Motors.

Next question: The new damper has a deep recess where for the crankshaft nut. What is the best way to access the locking washer to bend it up to lock the nut?

Thanks,

Peter Schauss

1963 BJ7

I successfully installed the combined damper and pulley that I got from Moss Motors.

Next question: The new damper has a deep recess where for the crankshaft nut. What is the best way to access the locking washer to bend it up to lock the nut?

Thanks,

Peter Schauss

1963 BJ7

Randy Forbes

Yoda

Offline

That would fall into the by any means necessary category! I think I would try levering it up with an appropriate-sized screwdriver, keeping the flat-blade parallel to a flat on the nut. If required, you could finish it off with a pair of Channellocks.Thanks for all of the suggestions so far. I pulled the timing chain cover and everything in there looked to be in good shape. (The engine has about 30k miles on it since it was rebuilt 19 years ago.)

I successfully installed the combined damper and pulley that I got from Moss Motors.

Next question: The new damper has a deep recess where for the crankshaft nut. What is the best way to access the locking washer to bend it up to lock the nut?

Thanks,

Peter Schauss

1963 BJ7

After more than six weeks of working on the car off and on, I have the car back on the road. As I mentioned in a previous post, the new lock washer barely fit into the recess in the new damper so that there was no way to get any tool on it to bend it up against the nut. I talked to the tech rep from Pro-Race and the Moss technical people and both agreed that if I using blue Loctite and torqueing the nut to 90 ft-lb would be sufficient. I will be checking it regularly.

If I had to do this again I would replace the bolts which hold the motor mounts to the chassis with longer bolts before lifting the engine. When reassembling the car, I spent a number of hours trying to get the holes to line up. Ultimately, I had to remove the carburetors and the heat shield so that I could get the mount on the driver's side bolted down.

Thanks for all of the advice.

If I had to do this again I would replace the bolts which hold the motor mounts to the chassis with longer bolts before lifting the engine. When reassembling the car, I spent a number of hours trying to get the holes to line up. Ultimately, I had to remove the carburetors and the heat shield so that I could get the mount on the driver's side bolted down.

Thanks for all of the advice.

Offline

I used studs and that allowed me to easily line up the motor mounts with the frame holes. Very easy to do with studs!After more than six weeks of working on the car off and on, I have the car back on the road. As I mentioned in a previous post, the new lock washer barely fit into the recess in the new damper so that there was no way to get any tool on it to bend it up against the nut. I talked to the tech rep from Pro-Race and the Moss technical people and both agreed that if I using blue Loctite and torqueing the nut to 90 ft-lb would be sufficient. I will be checking it regularly.

If I had to do this again I would replace the bolts which hold the motor mounts to the chassis with longer bolts before lifting the engine. When reassembling the car, I spent a number of hours trying to get the holes to line up. Ultimately, I had to remove the carburetors and the heat shield so that I could get the mount on the driver's side bolted down.

Thanks for all of the advice.