Offline

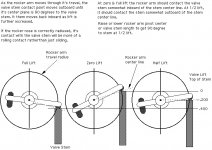

I am rebuilding the motor of my 100 BN1, I had the cam reground to M spec, neither the cam shop nor my machinist mentioned this, but the our local sports car mechanic/guru said I should do something about the rocker arm geometry change.

Should I?, I assume shaving the pedastals a hair would be the best way to put the geometry back to where it had been before.

Should I?, I assume shaving the pedastals a hair would be the best way to put the geometry back to where it had been before.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>