aeronca65t

Great Pumpkin

Offline

This brutal Winter combined with other projects at work and at home have kept me away from working on #909. But I knew I needed to get back into the engine before the '14 race season started.

For one thing, the 1275 is pushing a bit of oil out of the rear main scroll "seal". I haven't really changed anything in terms of crankcase venting so I've been assuming crankcase pressure has increased for some reason. The engine has about 50 hours on it, so it's due.

It's important to note here that the engine was running OK and still able to pull almost 7000 in 4th gear. But the oil leak spoke to emerging, related problems. I've been decent with maintenance; new oil / filter every event (20W/50 racing). Valves checked/adjusted regularly (although these are stock rockers so they are hardly ever off at all).

Last week, with reasonable temps, I decided to do a leak down test. The test confirmed my guess: 60% leak down in cylinder #3 with others in the 40% range. During the test I also ran about 60 psi directly to each cylinder and used a piece of 3/4" plastic pipe (as a sort of primitive stethoscope) to listen for leaks. Cylinder #3 was allowing a lot of air into the sump (I could hear it via the dipstick hole). And cylinder #2 was allowing a lot of leakage via its intake valve (it was audible from the from carbs).

So, off comes the head.

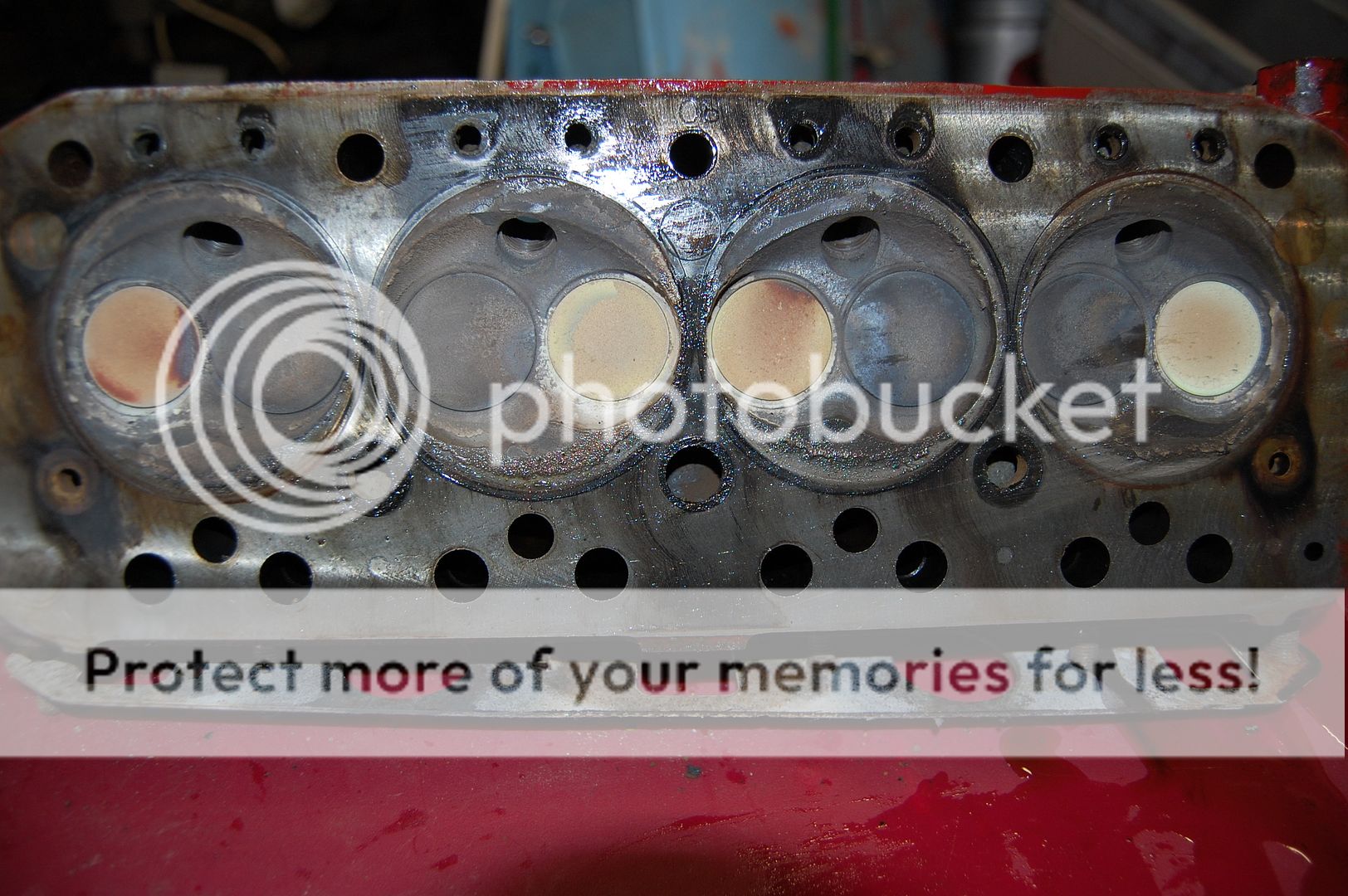

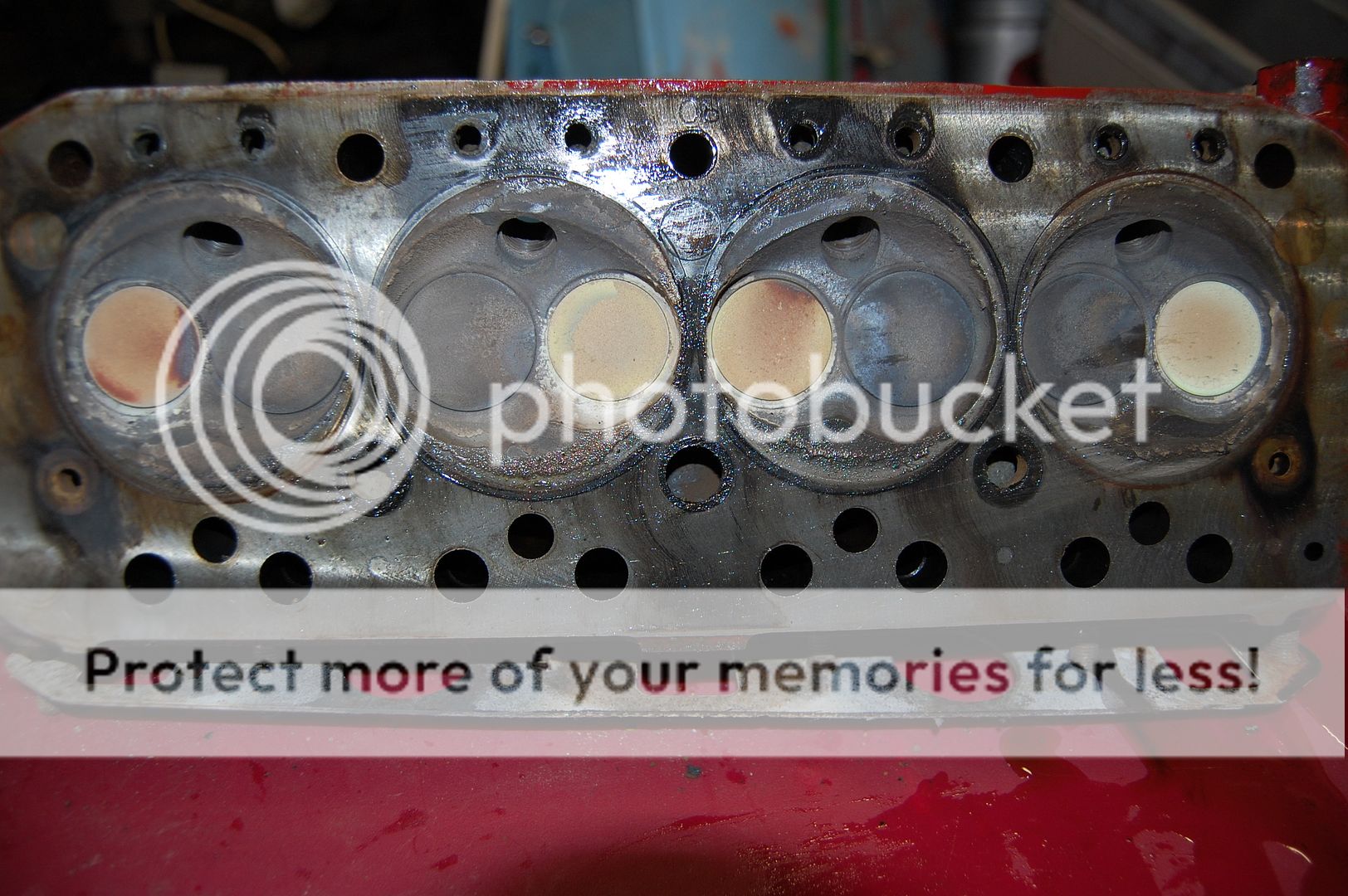

None of the valves actually looked too bad. Margins are a bit skinny (I ground them 2 years ago) so I will replace all with new ones.

Head gasket looks like it may have been compromised between #2 and #3. I'll have to look at that.

Ring end-gaps were all pretty loose. Cylinder #3 was over 0.035" (it should be around 0.010" or so). One ring came out cracked but that may have been my fault. There was a large built-up of crud at the top of the bore and I may not have cleaned it up as well as I could have before knocking out the piston.

One thing that I always notice is the excess build-up of crud on valves, pistons and the upper cylinder bore. I would guess these are lead deposits because I never see this much gunk on cars running unleaded street gas. I'm also running a slightly rich fuel mix, but this looks more like lead than carbon.

I think the heavy bore deposits may be related to the fact that the 21253 AE pistons place the upper ring pretty low relative to normal pistons. This make the upper part of the piston stronger but leaves a space for deposits to build up

When I had my first MGA back in the '60s, this sort of heavy lead deposit was common (I don't really think it's carbon). Build up of lead on plugs was very noticeable even after 1000 miles. The owner's manual for my old TR-3 used to advise that you should "remove the head and de-coke every 10,000 miles".

Two of the pistons I removed have scuffing on the skirts of the pistons. I'm not sure why; the other two are perfect. So I'll buy two of the 21253 pistons (+.040) and re-ring the old pistons. Then I'll balance the piston/rod assemblies, run a dingleberry hone up and down the bores and hope for the best. These are pretty mild, dished pistons designed for 9.75:1 compression.

Combined with a "fast road" cam (276 Kent), stock carbs and a non-LCB header the engine is overall, pretty mild. I'd guess maybe 75 horsepower.

Rod bearing journals measure good so I'll just replace them with new tri-metal bearings (-.010" in my case).

Right now, I'm waiting for parts from Moss and 7Enterprises. Then the fun part begins.

For one thing, the 1275 is pushing a bit of oil out of the rear main scroll "seal". I haven't really changed anything in terms of crankcase venting so I've been assuming crankcase pressure has increased for some reason. The engine has about 50 hours on it, so it's due.

It's important to note here that the engine was running OK and still able to pull almost 7000 in 4th gear. But the oil leak spoke to emerging, related problems. I've been decent with maintenance; new oil / filter every event (20W/50 racing). Valves checked/adjusted regularly (although these are stock rockers so they are hardly ever off at all).

Last week, with reasonable temps, I decided to do a leak down test. The test confirmed my guess: 60% leak down in cylinder #3 with others in the 40% range. During the test I also ran about 60 psi directly to each cylinder and used a piece of 3/4" plastic pipe (as a sort of primitive stethoscope) to listen for leaks. Cylinder #3 was allowing a lot of air into the sump (I could hear it via the dipstick hole). And cylinder #2 was allowing a lot of leakage via its intake valve (it was audible from the from carbs).

So, off comes the head.

None of the valves actually looked too bad. Margins are a bit skinny (I ground them 2 years ago) so I will replace all with new ones.

Head gasket looks like it may have been compromised between #2 and #3. I'll have to look at that.

Ring end-gaps were all pretty loose. Cylinder #3 was over 0.035" (it should be around 0.010" or so). One ring came out cracked but that may have been my fault. There was a large built-up of crud at the top of the bore and I may not have cleaned it up as well as I could have before knocking out the piston.

One thing that I always notice is the excess build-up of crud on valves, pistons and the upper cylinder bore. I would guess these are lead deposits because I never see this much gunk on cars running unleaded street gas. I'm also running a slightly rich fuel mix, but this looks more like lead than carbon.

I think the heavy bore deposits may be related to the fact that the 21253 AE pistons place the upper ring pretty low relative to normal pistons. This make the upper part of the piston stronger but leaves a space for deposits to build up

When I had my first MGA back in the '60s, this sort of heavy lead deposit was common (I don't really think it's carbon). Build up of lead on plugs was very noticeable even after 1000 miles. The owner's manual for my old TR-3 used to advise that you should "remove the head and de-coke every 10,000 miles".

Two of the pistons I removed have scuffing on the skirts of the pistons. I'm not sure why; the other two are perfect. So I'll buy two of the 21253 pistons (+.040) and re-ring the old pistons. Then I'll balance the piston/rod assemblies, run a dingleberry hone up and down the bores and hope for the best. These are pretty mild, dished pistons designed for 9.75:1 compression.

Combined with a "fast road" cam (276 Kent), stock carbs and a non-LCB header the engine is overall, pretty mild. I'd guess maybe 75 horsepower.

Rod bearing journals measure good so I'll just replace them with new tri-metal bearings (-.010" in my case).

Right now, I'm waiting for parts from Moss and 7Enterprises. Then the fun part begins.

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>