-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question about jack stands

- Thread starter nevets

- Start date

bob hughes

Luke Skywalker

Offline

I use axle stands under the frame with wooden blocks as spacers, I notice that if I put them front and back, the front being somewhere around the front suspension position and the back at the rear of the rear suspension, the door gap closes. This is due to the fact that the rear suspension pick up points are quite far apart and where as the axle shares the load between the two, I am putting the load on the rear end as it were.

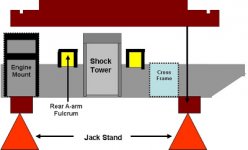

I place the hydraulic jack under the front suspension area with a spreader bar across the frame and to the rear I place it under the rear cross member with a spreader bar across the frame.

Bob

I place the hydraulic jack under the front suspension area with a spreader bar across the frame and to the rear I place it under the rear cross member with a spreader bar across the frame.

Bob

Keith_M

Jedi Knight

Offline

I have put my Healey on 4 jack stands many times, trying to position them as close to the suspension mounts as possible. I have never noticed the door gaps closing up. However, my car underwent a complete restoration, and we replaced the inner sills using the now-available heavier gauge replacements. I suspect that older cars with the original sills and possibly with some rust weakening of the sills might have enough flex to close the door gap a little. I suppose you could avoid the problem Bob describes by placing the rear jack stands under the axle.

Bob_Spidell

Yoda

Offline

Unless I need to unload the coils, I put quality jackstands--the kind with the solid iron, Y-shaped yokes--under the A-arms just outboard of the spring pan. In the rear I put quality jackstands under the leaf springs just behind the U-bolt brackets (don't want to mess up the threads of the U-bolts). Of course, you should be on level, flat and strong concrete only. FWIW, my BJ8 was suspended in this fashion and rode through a ~4-Richter earthquake without budging.

If I need to unload the coils I put a 2x4 under the chassis crosspiece by the radiator with jackstands on either side. I also use the 2x4 to jack up the front; on the rear I use the diff with a pan on the floor jack (that's a no-no for some cars like my Mustang, but I think the Healey axle housing can handle it).

If I need to unload the coils I put a 2x4 under the chassis crosspiece by the radiator with jackstands on either side. I also use the 2x4 to jack up the front; on the rear I use the diff with a pan on the floor jack (that's a no-no for some cars like my Mustang, but I think the Healey axle housing can handle it).

drambuie

Jedi Warrior

Offline

If your not doing wheel work, Rino ramps work very well! However, No matter if im using jack stands or ramps... I always shore up the frame with a stack of 4x4s just as a back up! I had a jack stand go right through a frame member one time! Grease was hiding the frame rot! That Tr4 fell faster then i could say it! I was just about to crawl under for a inspection! I still think about it every time i jack up a car.... I won't trust just one set of anything anymore!

bob hughes

Luke Skywalker

Offline

Wow drambuie, that was a lucky break - pardon the pun

Bob

Bob

RAC68

Darth Vader

Offline

Iusually place jack stands under the front suspension and under the rear crossmember on wood pads when the car is in the air. Also, if not supporting the car from under the suspension and as per themanual, I placing a 2” wood block under the shock arm for front suspension supportand to eliminate stress on the rubber rebound bumper.

When repairing my frame tare with the suspension removed, I supported the carby placing 2 cut 4x4s under the frame. The cuts were made to secure sidemovement and also to relieve space for the frame weld. Later, I installed abolt and 2 large washers just before each main cut to (hopefully) preventseparation when jacking from the center of the beam. These beams allow me tomove support and stability to additional areas of the frame as when working onthe tare or removing the suspension.

Ray (64BJ8P1)

When repairing my frame tare with the suspension removed, I supported the carby placing 2 cut 4x4s under the frame. The cuts were made to secure sidemovement and also to relieve space for the frame weld. Later, I installed abolt and 2 large washers just before each main cut to (hopefully) preventseparation when jacking from the center of the beam. These beams allow me tomove support and stability to additional areas of the frame as when working onthe tare or removing the suspension.

Ray (64BJ8P1)

Last edited:

drambuie

Jedi Warrior

Offline

Wow drambuie, that was a lucky break - pardon the pun

Bob

Hello Bob..... Yes... I still Thank God I wasn't tattoed to the bottom of that evel Tr4..... But it still left a big "impression" on me!